SCAMP Centerboard:

• I calculated area and depth required to pour 10lbs of lead in each half of the centerboard

• Based on 0.41lbs/cubic inch I decided to go with a cavity of 0.25”x6”x16.375” in each half. This is rounding up a bit, as I planned to fill any remaining void with epoxy.

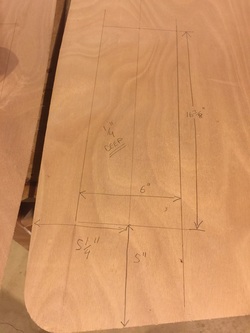

• Drew lines on each half of center board for cavity

• Used router to create the cavity in each side. I did not use a template or guide; just moved the router by hand, as I figured this was an internal cavity to be filled with lead and epoxy, and at such a low routing depth, very good manual accuracy can be attained.

• Based on 0.41lbs/cubic inch I decided to go with a cavity of 0.25”x6”x16.375” in each half. This is rounding up a bit, as I planned to fill any remaining void with epoxy.

• Drew lines on each half of center board for cavity

• Used router to create the cavity in each side. I did not use a template or guide; just moved the router by hand, as I figured this was an internal cavity to be filled with lead and epoxy, and at such a low routing depth, very good manual accuracy can be attained.

• Weighed 20lbs of lead, and threw in a bit over 20lbs by adding some sinkers, to account for lead that might remain in the melting

pot.

• Leveled the centerboard pieces in both directions

• Right around 0degF outside, chilly day!

• Propane stove melted lead fast, maybe 8 minutes to start melting, and once the pot was hot the new lead that I added melted

quicker than that.

•20lbs capacity cast lead melting pot was used.

pot.

• Leveled the centerboard pieces in both directions

• Right around 0degF outside, chilly day!

• Propane stove melted lead fast, maybe 8 minutes to start melting, and once the pot was hot the new lead that I added melted

quicker than that.

•20lbs capacity cast lead melting pot was used.

- I had 3lbs of lead left because the lead cooled so fast that I couldn't get the pour perfectly level (0degF temps outside the garage, with the other garage door open for ventilation didn't help it run smooth). So I added about 2.5" x 4.5" of 1/4" depth cavity per side and filled those with the remaining lead. 20lbs of lead poured.

- Then poured unthickened epoxy all around any voids over and between the lead and the routed cavity. Let cure overnight.

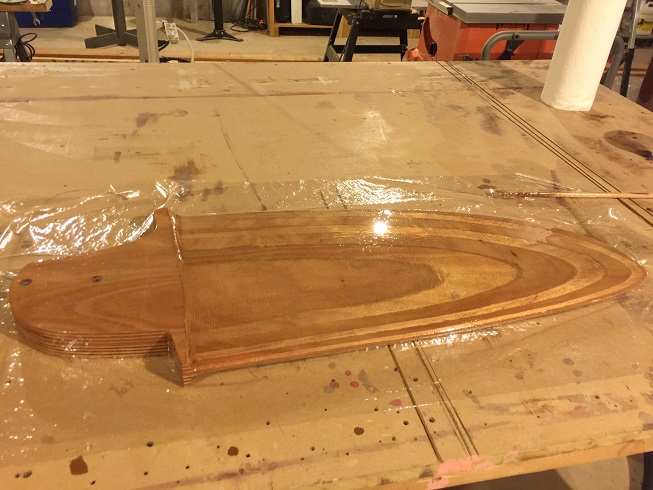

- Coated both inner centerboard faces with thickened epoxy and then clamped them together. Be sure to block up the centerboard in the middle, under the weight (tiles in my case), so that the weight in the middle does not create a bowed shape in your centerboard.

- I am now applying 2 layers of fiberglass to the "end grain" on the bottom of the center board, and wrapping that up the sides a bit, and one layer of fiberglass on the end-grain of the top/front/back flats of the centerboard

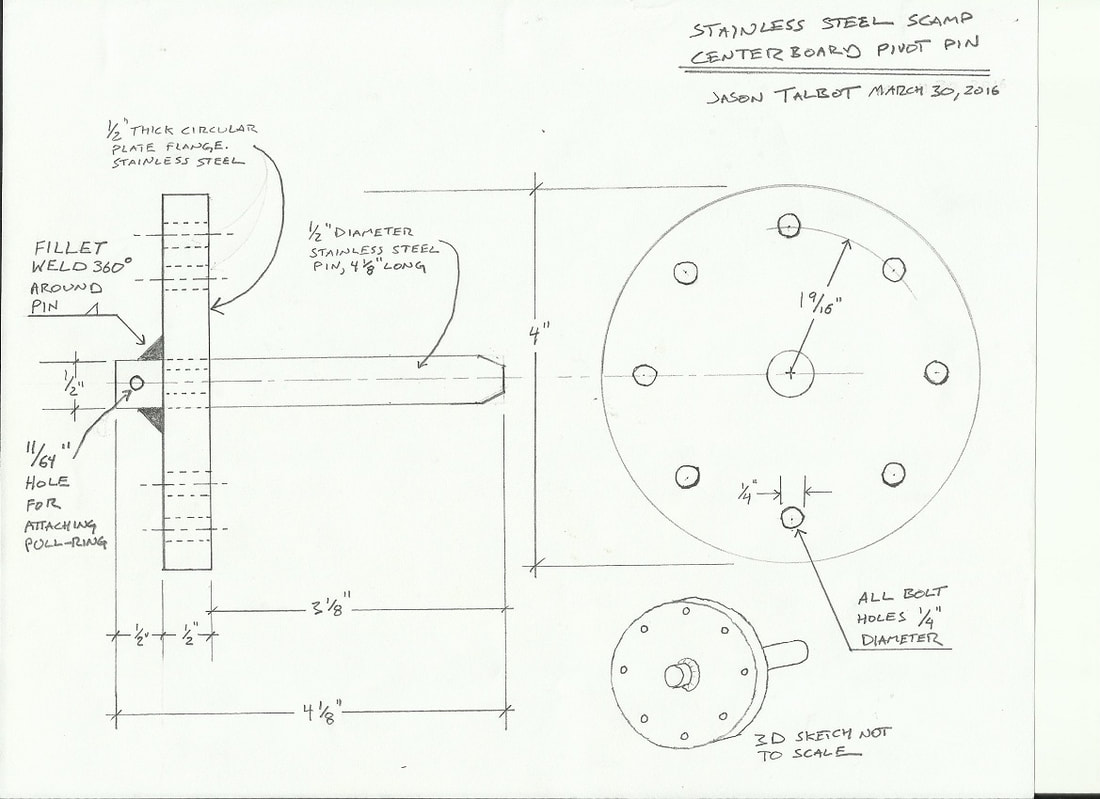

SCAMP Centerboard Pivot Pin

I wanted a strong centerboard pivot pin that would give me peace-of-mind regarding retention of the centerboard and elimination of risk of the pin backing-out. To that end, I designed a fabricated stainless steel flanged centerboard pin. I had purchased a stainless centerboard bolt, and was going to go that route, which is cheaper, and I have seen some great centerboard bolt retention designs out there....that said, I went a little overboard and went for the stainless fabricated centerboard pivot pin below. It will be retained using 1/4" stainless steel hex head lag screws. Based on feedback from Simeon, I updated the design to feature a more tapered end on the pin, and added a hole in the stub end, where a pulling ring can be anchored, in order to make pulling the pin out easier.

Later in the project, with the boat flipped upright, I installed the centerboard.

- Make sure the centerboard is supported from below so that it does not just fall through the centerboard case.

- In my case, the boat is on the trailer, and the trailer bunk is directly beneath the centerboard case.

- I dropped in the centerboard, careful not to pinch my fingers.

- I held a screwdriver (in my left hand) in the centerboard-pin-hole and shuffled the centerboard around with my right hand until the hole was found, then I held it tight with my right hand and pushed in the centerboard pin. This took a couple tries.

- The pin was then tightened down and I am very happy with the result.

That's all for now on the centerboard. For detail on the hardware used for centerboard tackle, visit the hardware page

For information on the final rigging of the centerboard uphaul, please visit the SCAMP Sailboat ARGO Rigging Page

SCAMP Tiller:

- Over the years my father has gathered up a reliable inventory of neat roughsawn hardwood boards, and looking through it with him today, we found an absolutely perfect tiger-patterned straight , tight-grained piece of hickory. This will be my tiller.

- There are some very detailed, well-dimensioned drawings online of tillers for SCAMP. That said, rightly or wrongly, I just unscientifically drew out by hand, my tiller on this piece of 1.375" thick by 43" long by 4" wide hickory that I found. I drew it with a curvature and taper that I thought looked good. Then I rough-cut the tiller on the bandsaw to create the blank below. I am excited about how it will look when carved, sanded and finished. I plan to finish it with 3 coats of epoxy and 3 coats of spar varnish.

SCAMP Rudder:

- As with the centerboard, the rudder materials were purchased from Small Craft Advisor. They send a rudder in two halves, that is already rough shaped to the correct foil cross section. The two halves must be glued together with epoxy, and covered with fiberglass.

- Mixed 6oz of slow set epoxy

- coated the surfaces to be glued together with thin coat of unthickened epoxy

- thickened the remaining epoxy with Colloidial Silicone

- Applied thickened epoxy to the surfaces to be joined

- clamped together with medium pressure and made sure the two halves were aligned to each other

- I had too much epoxy to chip off of my bench-top after gluing up the centerboard, so I wised up this time and put down Saran wrap under the rudder during glue-up.

- Centerboard and Rudder glued together and sanded:

- Fiberglassing the rudder. Cut a 36" x 16" piece of fiberglass. Mixed 6oz of slow set epoxy. Cut a slit where the sharp edge is located at the transition from the top of the rudder to the foiled section, did this to allow the fiberglass to break over this edge without "bubbling" up. Coated surface of one side of the rudder with epoxy. Layed down the fiberglass and coated the fiberglass with remaining epoxy.

- Trimmed the excess fiberglass with a razor knife and sanded it smooth. Flipped the rudder over, sanded off the epoxy that had dripped onto the other side (so that I would have a fresh clean wood surface to fiberglass-to). Applied fiberglass to the other side.

- Trimmed fiberglass

- Cut a strip to cover the "end-grain" at the top of the rudder, and held rudder in a vertical position

- fiberglassed top of rudder

- Gave the rudder a sanding and clamped it in a horizontal position, leading edge pointing up

- Applied an 8" wide strip of fiberglass on the leading edge of the rudder, carried over each side 4". filled the fiberglass and also gave the whole rudder a coat of epoxy

- I was concerned with durability of just one layer of fiberglass on the rudder, so I went for a final complete coverage of fiberglass. This will result in two layers of fiberglass on the whole rudder and 3 layers on the leading edge. Third layer being applied below.

- Sanded rudder

- 2 more epoxy coats in progress:

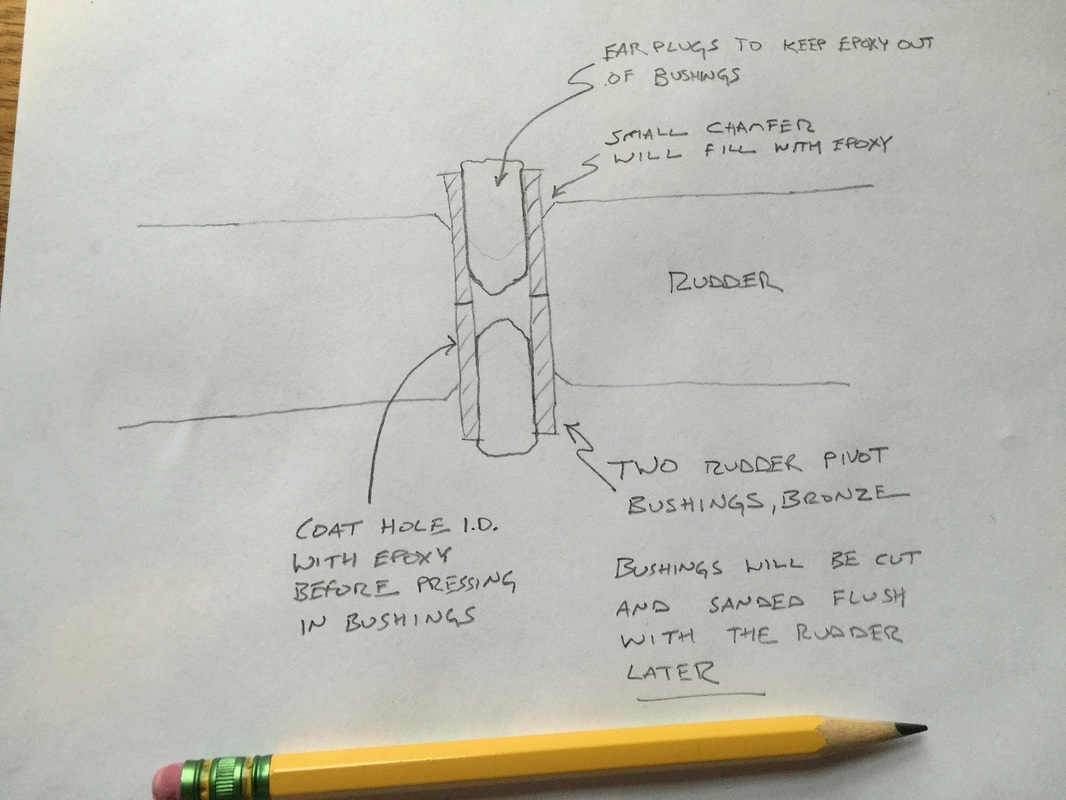

Above photo: 3/8" hole drilled for rudder uphaul: this will be filled with epoxy and drilled to 1/4" to accept the 1/4" rudder uphaul line. 1/2" hole drilled for rudder pivot (will have bushings installed in it), and 1" diameter hole drilled to provide access to rudder-downhaul. A 3/8" hole is drilled into the end of the rudder: this hole will be filled with epoxy and a 1/4" hole will be drilled through the epoxy for the rudder downhaul line. Downhaul line alignment groove has been cut into the top of the rudder with a file.

- Then applied three coats of Epifanes Gloss Spar Varnish

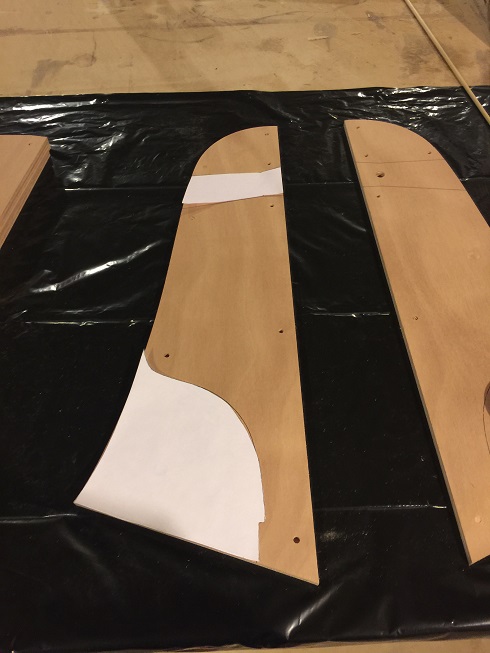

Starting construction of the SCAMP rudder Head Stock. I purchased the SCAMP kit from SCA, which included these parts. The internal blocking is made from glued up sheets of plywood and the outer stock plates are plywood also. Here I have traced out the areas where the tiller and rudder-foil will be. There is no blocking in these areas, and I will fiberglass and graphite-epoxy them to provide abrasion resistance to the motion of the rudder foil and tiller.

- Next, I drilled two 1/4" holes for the copper rudder uphaul/downhaul tubes. The 1/4" holes were too small and tight to fit the 1/4" copper tube through, so I drilled them to 5/16" diameter.

- Flared one end of each copper tube, filled the holes with epoxy and then pushed the tubes up through the liquid epoxy so that they were completely encased in epoxy. I filled the ends of the tubes with modeling clay to keep epoxy out.

- After the epoxy mostly hardened but was still malleable, I cut and flared the other end of the tubes. I flared by pounding the tube-ends with a conical piece of steel, worked well.

Jam cleats installed on underside of tiller. Uphaul line length was cut such that when extended 2 wraps around the jam will leave a short tail, and then retracted 3 wraps will leave a short tail. In the photo the red line (uphaul) has two wraps, and the blue (downhaul) has three. If I raise the rudder the red line would be reset with three wraps and the blue with two; and there would not be long tails after the cleats. The first really holds the line enough, and subsequent wraps are to keep lines tidy.

A bowline makes the uphaul fast to the tiller. The hole in the tiller was drilled oversize, filled with epoxy, and then drilled to final size. The downhaul line enters the head of the rudder through a hole similarly made, and then a figure eight stopper knot dipped in epoxy forms the stopper inside the rudder.

Note the auto-release camcleat added to the bottom of the tiller. In shallow water, I will be able to use this in lieu of the jam cleat, for the rudder downhaul. In the event of the rudder hitting bottom the auto-release cleat will allow the rudder to pop up. I also switched the lines to Hempex, which will be used throughout the rigging (other than the anchor rope....because hempex floats)

Detail on mounting the gudgeons to the transom may be found on the Mounting Hardware Page