November 3, 2023

Below is a complete build-log of my progress as I built this guitar. First, some pictures of my finished guitars:

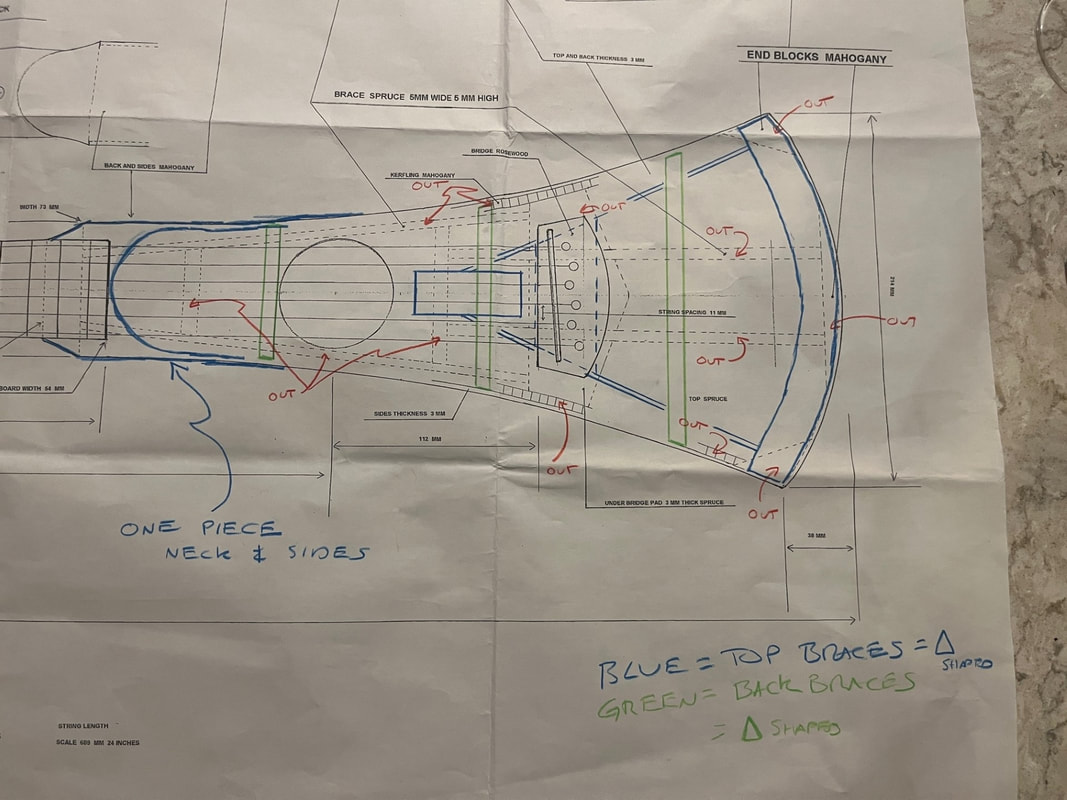

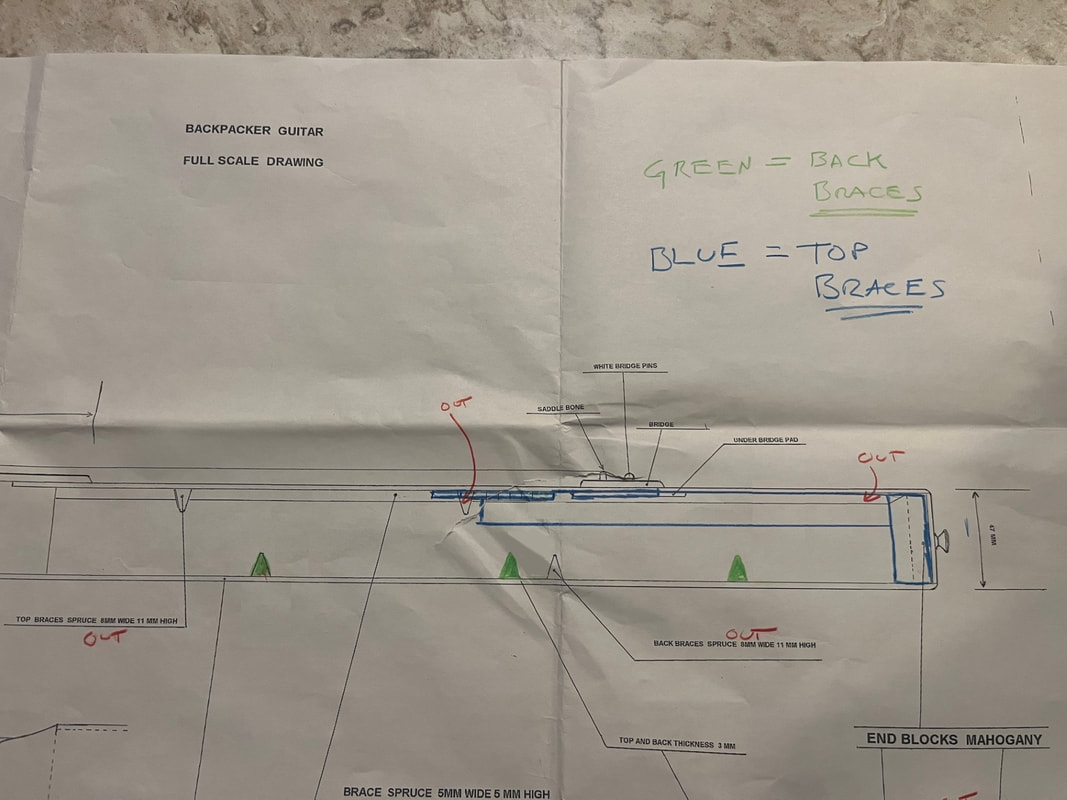

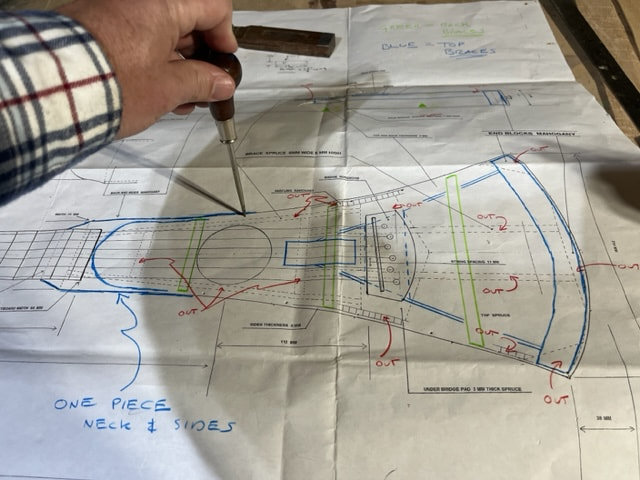

Drawings for a guitar in the style of the Martin Backpacker Guitar:

Further down the page is the fun photo journal of building this guitar, but first some technical notes on the drawing I used. You will find these notes helpful if you intend to build this guitar using the drawings I also used.

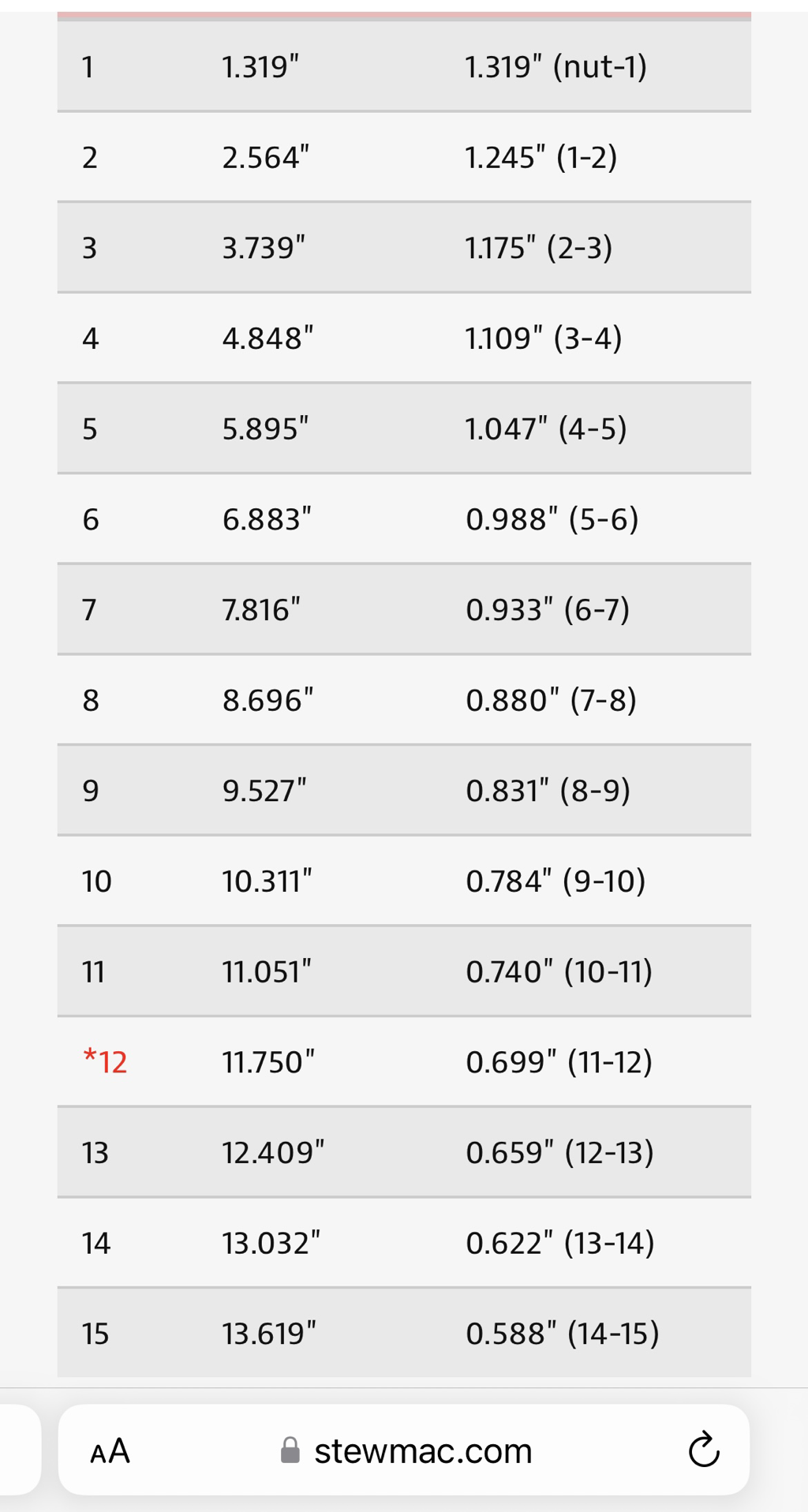

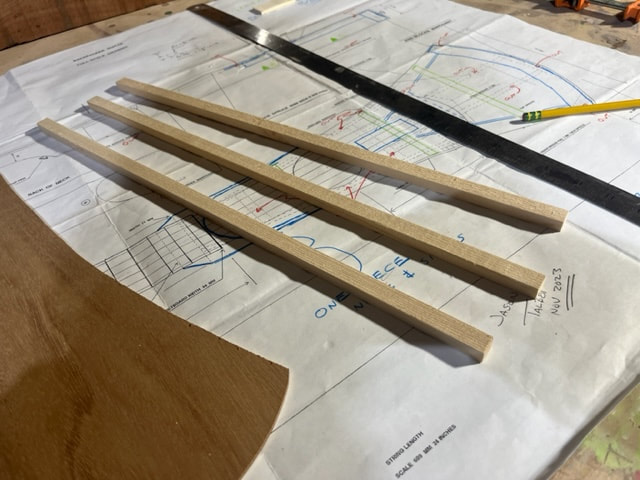

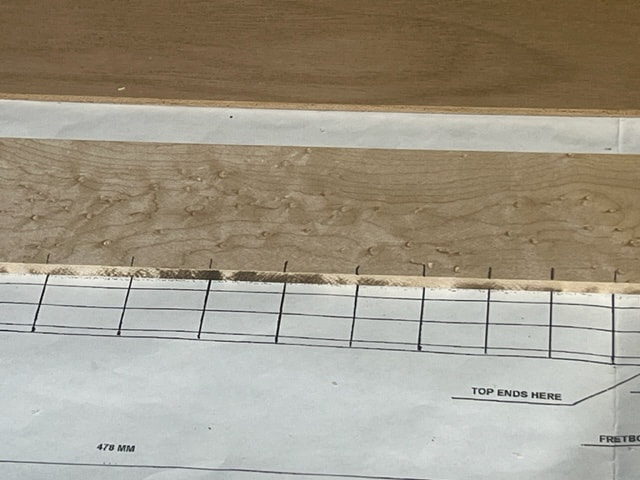

I bought a full size set of drawings from ebay that say they were made by Jesus Raymond. It is an OK full size print, with metric and imperical calculations/dimensions shown for fret locations. I checked the overall outer dimensions, and they seem correct but there are real issues , in my opinion, with the drawing itself and the dimensions provided. The biggest issue with the drawing and dimensions regards the fret locations and scale. According to Stewmac, the scale is the distance between the front of the nut and the top of the saddle; and the distance from the nut to the 12th fret should be half this length. Be aware that Mr.Raymond’s design considers the scale to be the distance from the nut to the string pegs. On the drawing this would indicate a scale of 23.5”. The fret locations on the drawing are correct for this 23.5” scale but be aware that the fret spacing in the written charts on the drawing correspond to a true 24” scale and these dimensions do not match the drawn lines on the drawing. Below I show the recalculated fret spacing that I used, which was done using on Stewmacs standards and calculator based on a 23.5” scale. I had already glued on my bridge and drilled peg holes when I noticed this so I stuck with the 23.5” scale. If you want to use the written out fret spacing on the drawing, which correspond to a true 24” scale, then I would move the bridge back such that the saddle was 24” from the front of the nut. The internal construction details such as kerfing and bracing on Jesus Raymonds design are different than those on the Martin Backpacker; perhaps they are is improved recommendations. I will utilize the design elements from Martin, not from Mr.Raymond, as I think Martin must have thought their design through quite a bit and they build very many of these. This was the only drawing I could find to launch my project; just use this drawing with caution.

I found a youtube video showing the disassembly and repair of a Martin Backpacker, which shows the Martin design of internal braces and such. https://www.youtube.com/watch?v=IcMx2hm6y28. Thank you Dave Moore for this very helpful video. Here are some key photos from Dave Moore's video, showing the inside of a Martin Backpacker Guitar.

Fret spacing I used:

This is the distance from where the nut meets the fretboard to the centerline of the fret.

Very noticeable to me is the thick mahogany bracing/liner at the butt end of the Martin Backpacker. To me , this would add both needed counterweight, and also durability for when the guitar is set down. I will be using this very thick liner at the bottom of the interior of my guitar. Current Martin Backpackers are built with sides that are separate pieces of wood from the neck. I plan to build the neck and sides of my guitar from one solid piece of wood, as I think earlier backpackers were made.

I thought the bridge on the drawing also looked far too thin, so I will make it 11/32" thick as shown in my sketch below.

Other items that I will not make according to Raymond Jesus' design are:

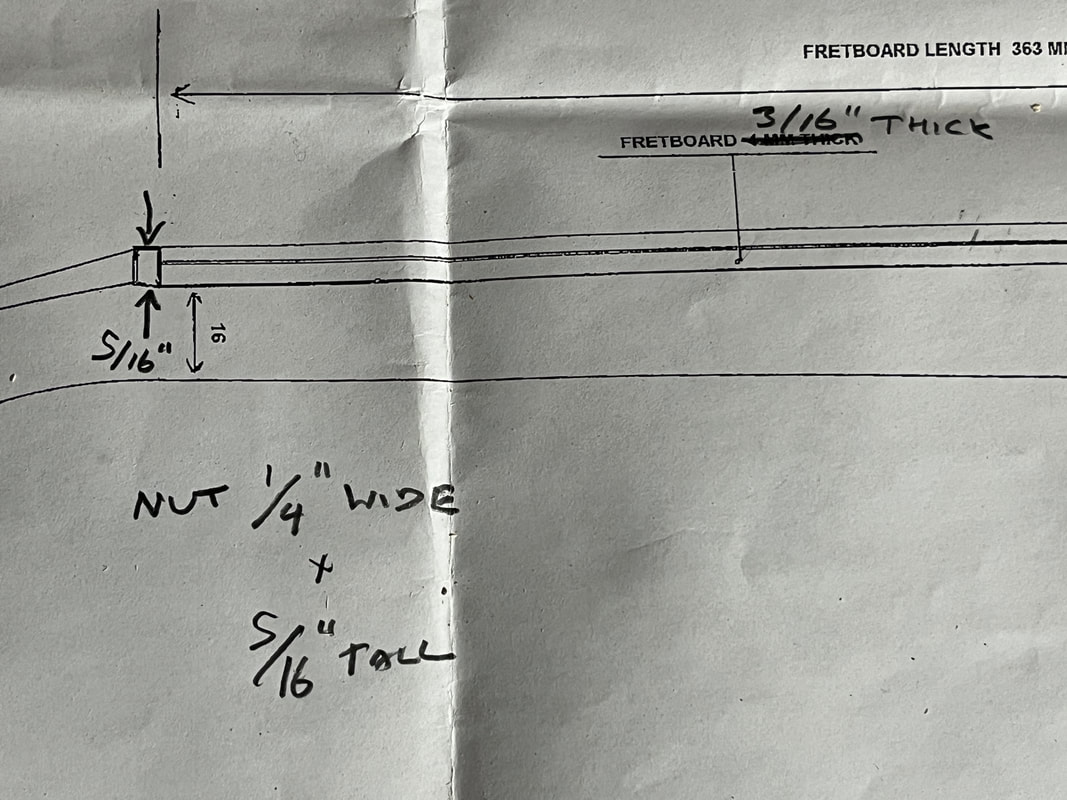

- The nut on his drawing looked narrow and short, I will make one 1/4" wide and 5/16" tall. NOTE that final dimensions will be determined when I finish the guitar and I will adjust the NUT height to achieve the correct spacing of the strings above the fretboard. Same story with the bridge and saddle, I will make final adjustments and dimensions may be different than my sketches/notes here.

- The fretboard on the drawing was 5/32" thick I will make mine 3/16" thick

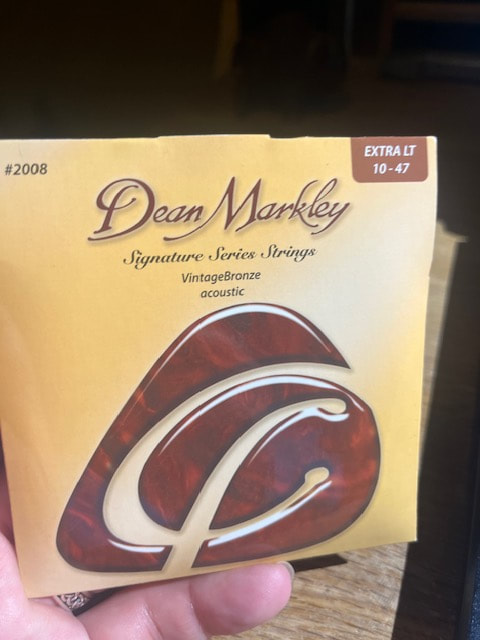

Materials I Used For Building My Backpacker Guitar

Some ideas for places to look for these materials would be: Kettle Moraine Hardwoods, Stewmac, Ocooch Hardwoods, Bell Forest Products.

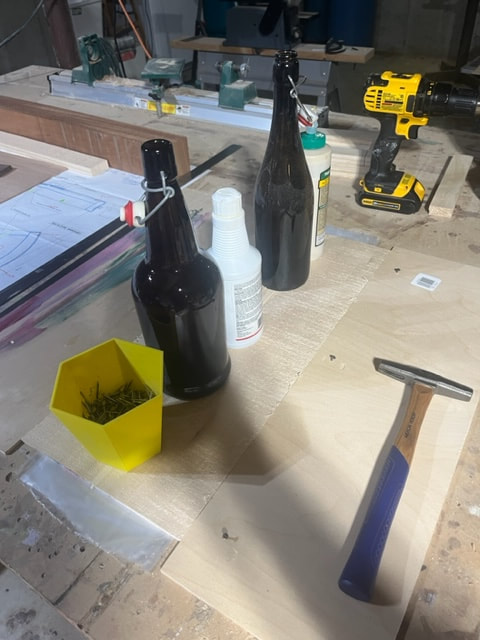

Tools: Straight edges, squares, sliding bevel, japanese pull saw, planes, xacto fine tooth saw, hammers, mallets, compass, awl, chisels, shinto rasp, spoke-shave, small and large files, files, drill bits and large forstner bits, clamps, measuring calipers, dremel, drill press, table saw, surface planer, band saw, random orbit sander, belt sander, miter saw, razor blades, bench vise....etc...

Now for some specialty fixtures and tools that I think will help me build this guitar:

Making a Saddle Routing Fixture

I ordered all of the wood for the guitar (learned these fine guitar-worthy woods are called "tonewood".). As I wait for it to arrive, I will build a little jjig to guide my dremel/router in order to make a properly oriented, and straight, and correct length groove in the bridge for the saddle to press into. A sketch of my design is below.

Gluing up the bottom plate and the middle layer that includes the recess for the bridge to fit snuggly into. I wil place the bridge blank in the recess, clamp of the top frame/router-guide frame, and then rout the slot. I drilled a couple holes through the bottom plate to allow me to pop out the bridge when I'm done.

Making a Fret Saw

Or more accurately; improving a fret saw. I bought a fret saw to ensure the width of the blade was correct, but saw some photos of other fret saws that had nice adjustable depth-fences built right in. I decided to make an adjustable brass depth gauge/fence for my fret saw.

Now, On With The Show! Building the Backpacker Guitar: First I will show how I built the various pieces and further below I will show final assembly and finishing.

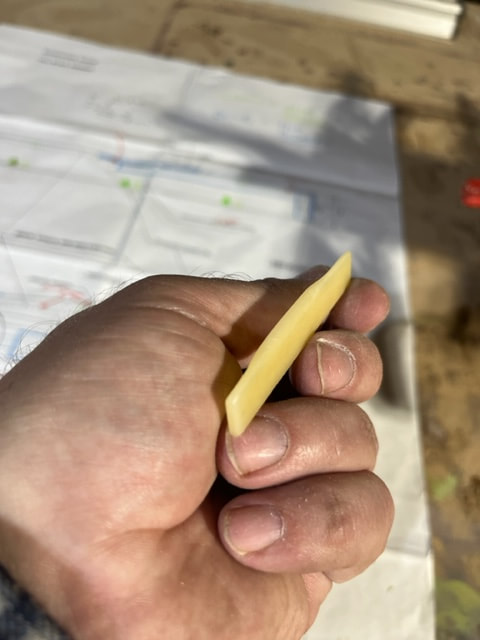

Making the nut and the saddle from unbleached bone

I cut the saddle to length with a fine-toothed x-acto saw, and used a file to shape it, then sanded with fine sandpaper.

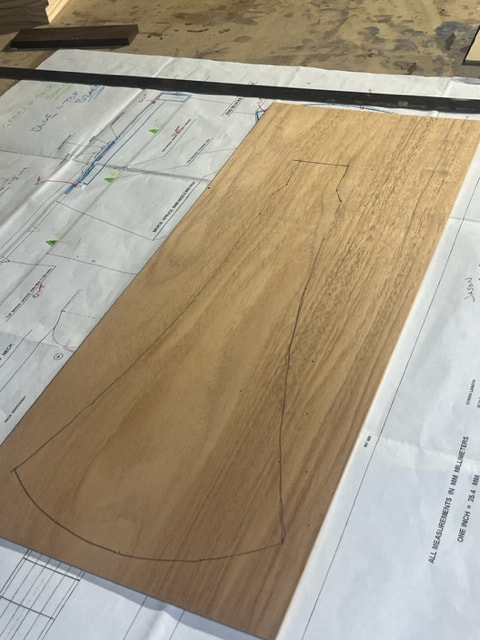

Making the Front and Back Pieces

I will make the back from a single piece of solid Mahogany, 1/8" thick.

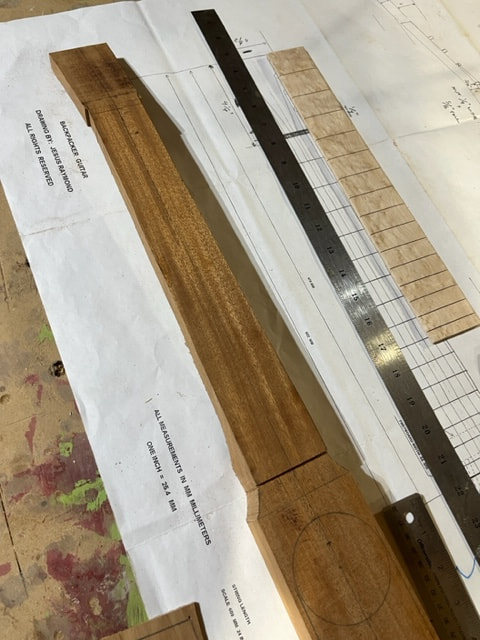

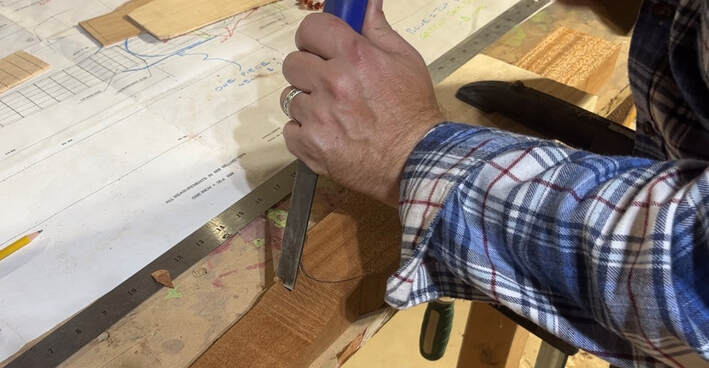

Making the Fretboard

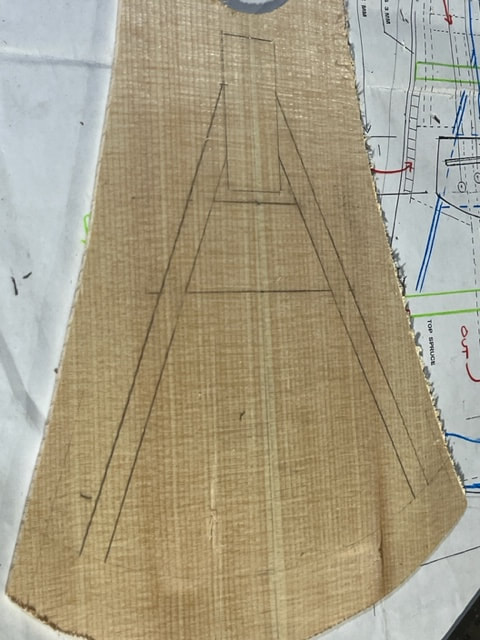

The fretboard will be made from birdseye hard maple. First I planed it to the correct thickness, then I cut it to the correct max width and length. Then before cutting the tapered shape of the neck, I marked out the fret locations and used a square to mark out nice perpendicular lines for the frets.

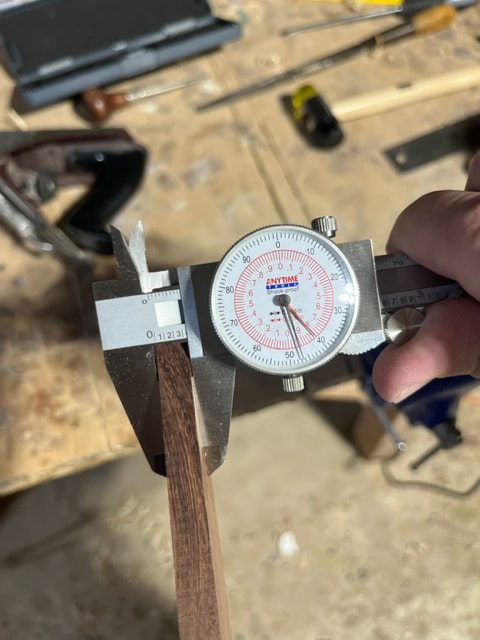

Making the Rosewood Bridge for My Backpacker Guitar

I practiced using scrap wood before making the Rosewood bridge. I needed to trial and error the slot cutting jig especially and try different router bits. I wound up buying some tiny metric slotting router bits that worked best as 1/8" bits made a slot to big. I also used scrap wood to get the depth of cut just right.

Making the Neck and Body for My Backpacker Guitar

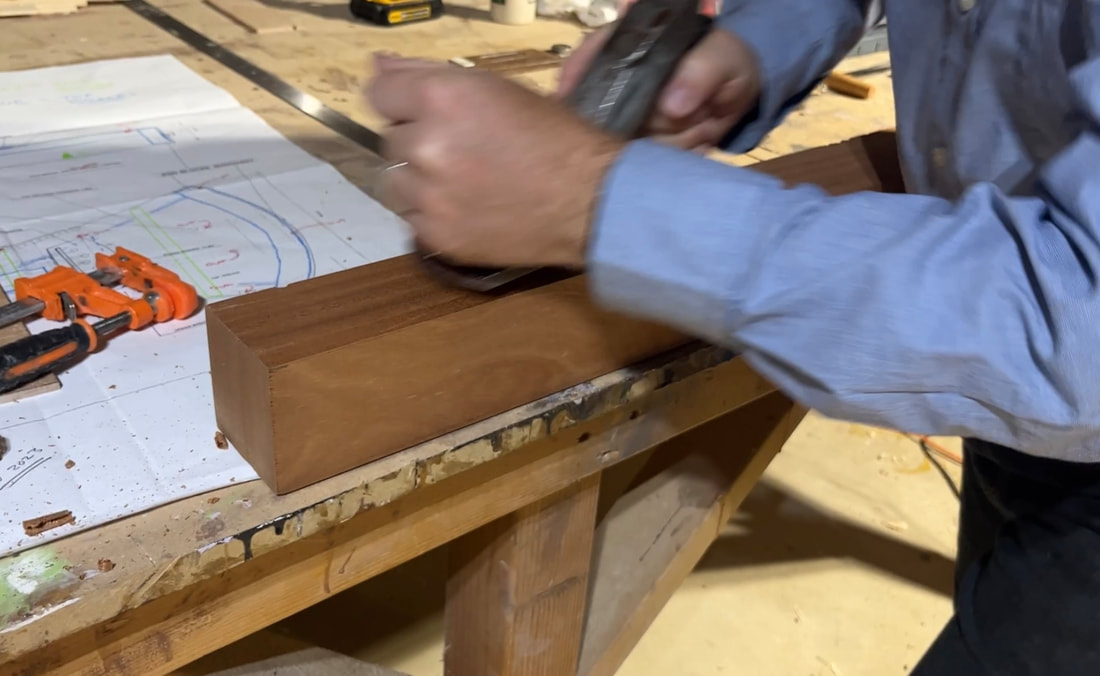

It seems that the current version of the Martin Backpacker Guitar has body-sides that are glued to the neck. I have heard that older Backpackers had body sides that were made in one single piece along with the neck, and that is how I will make mine. I started with a 3"x3" piece of mahogany that is a bit longer than the overall guitar.

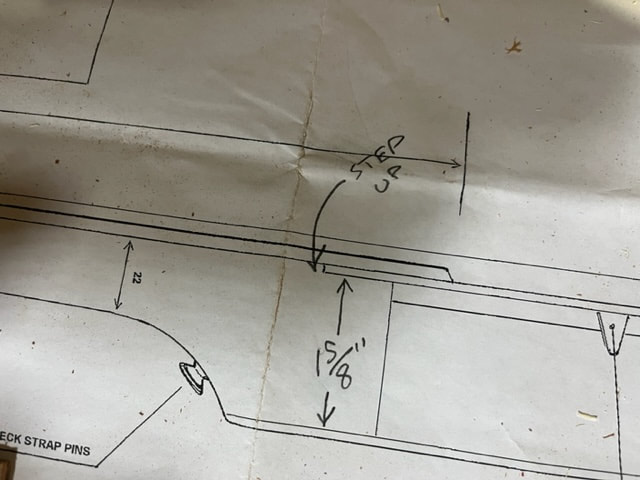

I miss things from time to time, and here is an example; I checked the height of the sides of the body and it is 1 5/8" but up at the transition from the body to the neck the top side of the piece of wood needs to step up and 1/8" at the point where the top ends, so the total height of the single-piece neck/body/piece would need to be 1 3/4".

sooo....... I glued a piece of the mahogany left over from the original 3"x3" post to the neck to account for this step up. I measured the exact location where the top ends and this is where I began the glue-up of this piece to the neck.

Drilling the tuner post holes to 3/8" didn't go well. I drilled a pilot hole which went fine but when I went to drop the 3/8” holes the wood split and I had significant blow-out of surface wood at the exit face of the bit! Uf-da. I epoxied the stock back together and used wood-flour-thickened epoxy to fill any voids. I wound up with a nice strong and smooth headstock with good tuner holes but I will need to enamel this section now due to the epoxy filler. Be careful when drilling these holes!!! I was going to fast and not careful enough.

Making the bending form for the body

To pre-bend the curved sides and the curved bottom wall of the body, I will be soaking the wood to be bent in hot water and then pressing it in a form. I have a few different sizes of stem boxes, but I do not want to steam the neck of this guitar so I will just soak the body portion and leave the neck above water. I made a form out of a 2 x 12 pine piece of lumber.

Bending Pieces and Assembling the Body

Finishing my Backpacker Guitar

Double checking flatness across the frets. I think there is a 1/100th to 1/64th more height over the highest pitch fret vs the longest fret and this may be an amateur construction error. I intend to string it up as-is but if it presents a playing problem, I will file down the middle fret to level it out.

Next I will apply 12 coats of Colortone Nitro Gloss Laquer from StewMac to my Backpacker guitar, sanding between every 3 coats with 320 grit paper.

I also put one coat of tung oil on the bridge.

Weaving, Stitching and Making the Guitar Strap

Making a Soft Case for the Backpacker Guitar

I will sew a soft case for carrying this guitar around. I think my daughter will want to play this guitar and carry it around so I think the case is a good idea. I will make it from durable canvas-type fabric with a protective liner, strap, and storage pocket.