Autumn 2018 project

The detail of a painting above is from Knud Bergslien's famous 1869 painting of the brave and dramatic rescue of a royal child by Norse skiers. https://en.wikipedia.org/wiki/Knud_Bergslien

Overview video showing the making of traditional wooden skis:

Building a Pair of Traditional Scandinavian Wooden Skis

|

Living in Wisconsin provides cold winter months in which one can hibernate indoors, or accept the reality, and go appreciate, and enjoy, the snow and ice. I enjoy downhill skiing, and at one point also enjoyed the fresh air and exercise of cross country skiing. This, combined with my interest in ye olde craftsmanship has led me to build a pair of traditional Scandinavian wooden skis which I will use to ski in the woods near my home.

The build-log with many photos of the making of these wooden skis may be found below. |

First some links to sites that helped me with research for my design and construction. It is amazing to see these truly authentic ski making videos. I am an amateur, but there are some pro's out there!

another Norwegian ski making video https://www.youtube.com/watch?v=UbPVqUbcjDY

vimeo.com/122003289 Norwegian traditional ski making video

www.dowe-ski.com

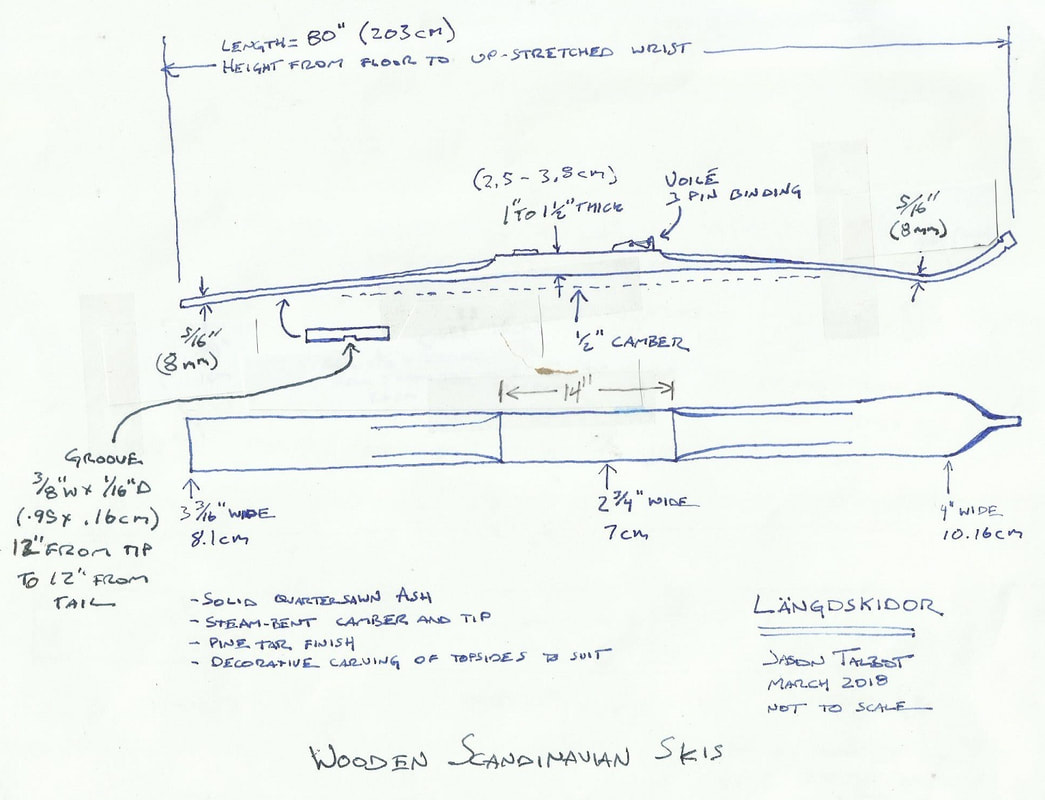

Now to the detail: Drawings for Traditional Wooden Skis

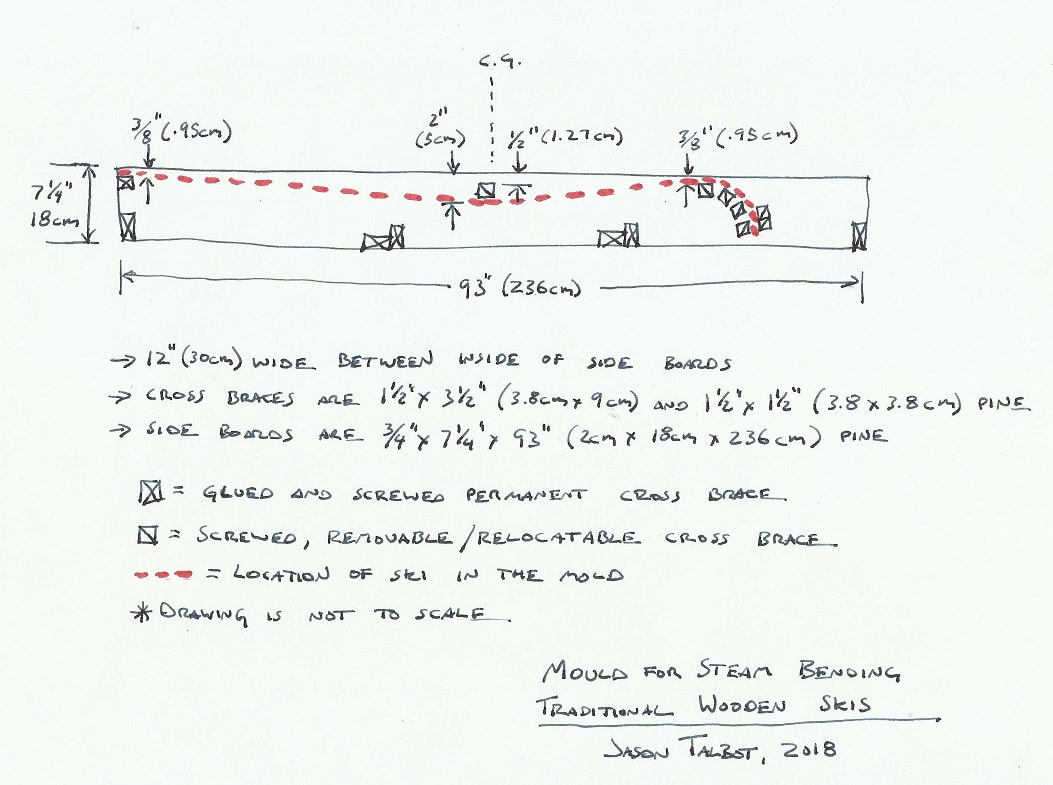

Step 1: Building the Form for Steam Bending Traditional Wooden Skis

First, I built the formwork that I will use to bend the skis to the curved final shape. I designed the frame to be adjustable so that I can build longer skis and skis of different camber and front-point-curve with this same mold.

Next I hand drew the curve at the front tip of the ski. I drew it a bit steeper than what I want the finished ski to be, as there will likely be some bounce-back after the skis are removed from the mold. In this photo, the cross brace farthest to the right is the key brace to keep the ski tip from popping up out of the mold.

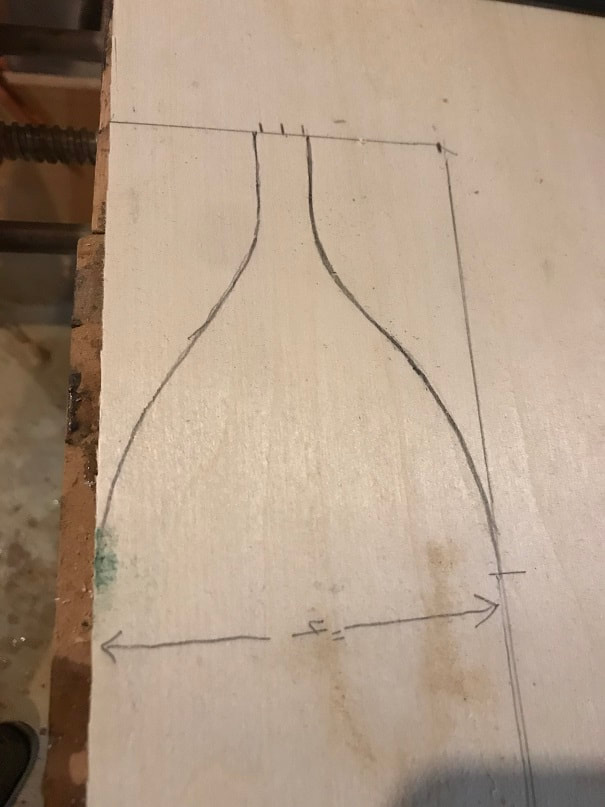

Step 2: Making a Template for the Shape of the Ski

I made a template using 1/4" (6.4mm) thick plywood. I think that by using a template I will have better consistency in shape of both skis. Also, I can reuse it in the future.

- I marked the length, and the width at the tip, tail and waist (middle).

- Drew the shape of the tip by hand

- Used a thin flexible wooden strip, that I would call a batten, to trace out the long curve on the sides of the ski.

Here's a video on using a batten to trace the long curve:

Step 3: Cut the shape of the ski from a square correctly sized piece of wood

Traditional skis in Norway were made from Ash, Elm, or Birch. Interestingly, in Norse Mythology Ash and Elm were the names of the first man and woman, as Adam and Eve are in Christianity. I will build my skis from Ash. I wanted quartersawn Ash, but I couldn't find any. Try to find air dried or lumber to work with rather than kiln dried, the former will bend, and retain the bend, better. The ski design and materials will be quite traditional, but I will use a semi-modern binding, and I will use modern tools to make the skis. I nice Swedish carving axe is a couple hundred bucks (carving axe is different than the typical hatchets/axes that we have), and I got this ash for $28, and I admit it will be quicker to use power tools for some tasks, so I am just going to use the tools I own (which will be a blend of power and hand tools) to make the skis. I may make another set using a carving axe in the future...

- I started with two pieces of rough-sawn ash 1.2" thick x 6" wide x 100" long. Rough sawn lumber is not uniform thickness, and is not straight, so it must be planed and trued up.

- First I used my power surface planer to create a uniform thickness with smooth top and bottom of the plank. The pieces are 1 1/16" thick (27mm)

- Then I used a long straight edge to draw a straight line along the edge of the boards. I used a circular saw to cut along this line, thereby creating a straight edge on one edge of the board.

- Next, I used a table saw and cut the board to 4.5" wide, with the newly cut straight edge along the fence of the table saw. Then I flipped it over and made one final cut at 4" wide so that both edges were finish cut on the table saw.

- Then I cut it to length at 80". So I had two straight, square, pieces of Ash 1-1/16" x 4" x 80".

I cut the shape using a saber saw with sharp new stout blade. Even with that, the blade was not able to hold vertical and it drifted at the bottom of the board vs the top of the board, so I cut a bit outside the line, and then used hand tools to square the edge and bring the shape up to the finished line. It would be best to use a band saw (or even better use a carving axe!)

Step 4: Sand Bottom and Cut Groove in the Bottom of the Skis

- Sanded bottoms with fine sandpaper on the belt sander; be careful as belt sanders are aggressive and can remove more than you want of you're not careful.

- I decided on a 3/8" wide x 1/16" deep groove for the skis. I chucked a 3/8" diameter, flat-bottom, router bit into my router, marked the centerline of the ski, set up a fence using a straight board, and cut in the groove. It starts 12" from the tip and finished 12" from the tail.

Step 5: Taper the Skis Down to 5/16" at the Tip and Tail

- First sketch out the taper on the side of the skis.

- Taper the ski with a plane on each edge, on a bevel, leaving a big ridge down the middle, then plan off the middle to achieve a flat top.

- It should be noted that the traditional method is to use a carving axe, which I do not own. A carving axe is beveled on one side only and would work great for shaping skis.....maybe I'll do it someday.

My skis will feature the traditional carved tip, called "the Ocean". This presents a challenge when tapering the front end of the ski, as one cant just plane right through the end of the ski. I reached a point where the tip was getting in the way of further planing, so I saw down just behind the tip and used a chisel to clear that area out.

Step 6: Carving the Decorative Tip of the Ski (the Ocean)

The carved tip of the ski, called "the Ocean" of the ski by the Norse, can be personalized to extent of the imagination of the carver. I chose to go with a simple circular design like that shown in the painting above. With the ski planed down to thickness, I drew out the shape I wanted to carve and then sawed and carved it to shape. DESIGN NOTE: I have been advised by some people that the decorated "ocean" should be carved on the down-facing side of the tip of the ski, not facing up as I did on this pair of skis.

Video of carving the ski tip:

Looking at pictures of old skis, it seemed that the carved ocean at the tip was more elegant and narrower (side to side thickness) so I narrowed mine up a bit, and I am happy with the result.

Step 7: Using a Scraper to Finish Smooth the Skis

I used a scraper to scrape the ski tops and bottoms smooth.

Step 8: Building a Steam Box For Steam Bending the Skis

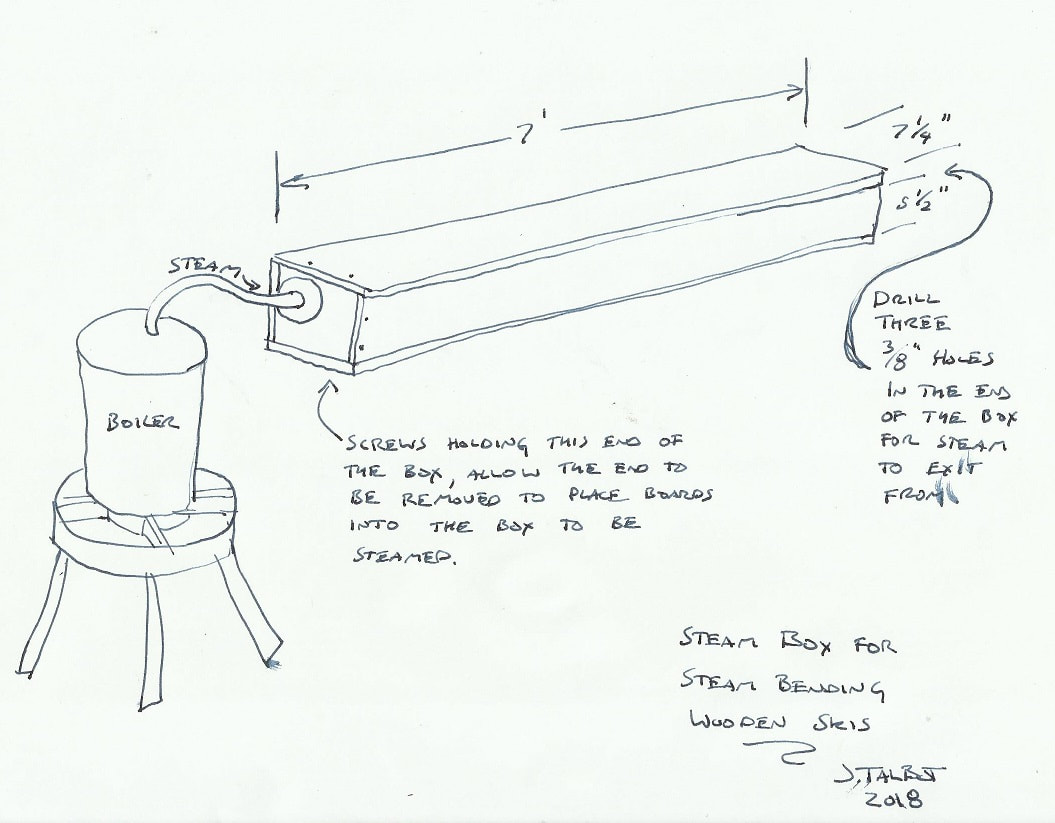

Here is a sketch of the steam box that I built. I tried to use the PVC steam tube that I used when building my boat, but the skis were too wide to fit in it, so I built this box.

- SAFETY NOTE: You follow my actions and plans at your own risk! I am not a professional wood steamer, and am not a professional steam box designer. Steam is dangerous; it can build up extreme pressures at burning temperatures, and an improperly built steambox could build too much pressure and a component of it could explode under pressure. Do not force steam into an enclosure without a way for the steam to safely exit the enclosure. Do not use materials in areas where they could start on fire or melt. If you are using fire to heat the water, do it in a safe place where you wont start other nearby things on fire; probably best to do this outside. Have a hose or fire extinguisher handy. Use materials that can withstand the pressure and temperature. Do not open up pots, containers, or boxes that are under steam pressure.

Step 9: Steam Bending Traditional Wooden Skis

At this stage I screwed the end of the box in place and connected the steam hose.

Next I secured the boiler top and fired up the boiler. I steamed the skis for one and a half hours.

Next I secured the boiler top and fired up the boiler. I steamed the skis for one and a half hours.

Step 10; Remove from Mould and Rescrape

Remove the skis from the mould after 3 days. The steam will have likely raised the grain of the wood, making the surface a bit rough again. I rescraped the tops, bottoms, and sides with the flat scraper.

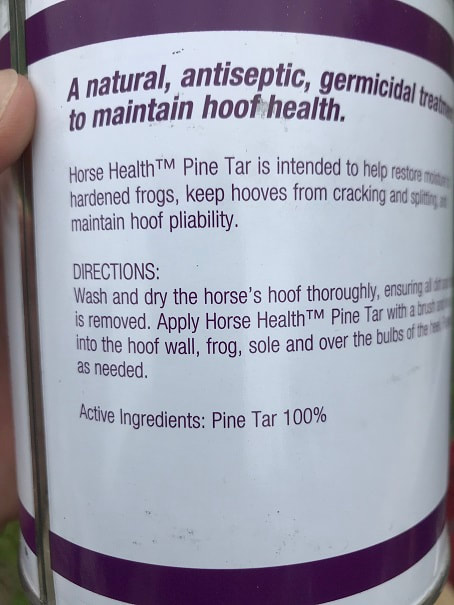

Step 11: Pine Tar The Skis

The traditional method for water-proofing and preserving wooden skis, was to treat them with pine tar; so that is what I will do also. In short, the pine tar is spread over the ski, then heated up to the boiling point, soaking itself into the ski, and then any residual surface pine tar is quickly wiped off.

What is pine tar? Here is a link to information on how it is made:

http://www.survival-manual.com/pine-tar.php

https://www.youtube.com/watch?v=PNf2Kre7ylI

http://www.survival-manual.com/pine-tar.php

https://www.youtube.com/watch?v=PNf2Kre7ylI

This is a potentially messy job best done outside or in the garage. Its late on September 28th and it in the low 50s and I set up saw horses to do this work outside.

Once the pine tar is liquid, use a chip brush to spread it over the ski. Some folks do a small bit at a time; I coated the entire top and sides of the ski at once.

Then use a flame-torch or a heat gun to heat the pine tar that has been applied to the ski. The tar will boil and soak into the wood. Work in 6" (15cm) sections heating and boiling the tar into the wood, and then wiping that section clean with a cotton rag. Work your way down the ski in this fashion. I did the tops and then each side. Then I flipped the ski and did the bottom. You will need to wipe off drips that drip from top-to-side and from bottom-to-side, as you go.

Then use a flame-torch or a heat gun to heat the pine tar that has been applied to the ski. The tar will boil and soak into the wood. Work in 6" (15cm) sections heating and boiling the tar into the wood, and then wiping that section clean with a cotton rag. Work your way down the ski in this fashion. I did the tops and then each side. Then I flipped the ski and did the bottom. You will need to wipe off drips that drip from top-to-side and from bottom-to-side, as you go.

At the end of the process, be sure to rub the pine tar off with a clean cloth so that no more comes off.

Step 12: Decorating the Ski Tops

I liked the look of traditional Scandinavian skis that had a pattern of parallel lines carved (or I would say scribed) into them. It was a quick fun project to make the 3 scribe tools below, from left over Ash from the skis. I drew out the distance from the edge that I wanted each scribed line, and set a nail at that distance in the tool. So, there is one scribe tool for each line on the ski. I also did not want to wear out my mortise gauge, so that's another reason I made these.

As I have seen on old classic skis, I decided to mark them with some details on the maker, location, and date. I did so with letter punches.

Step 13: Mounting Binding On Traditional Wooden Skis

As seen in some of the links above, the most antique bindings used by the Scandinavians, were made of twisted birch shoots. I selected Voile HD Mountaineer 3 Pin Bindings for my skis.

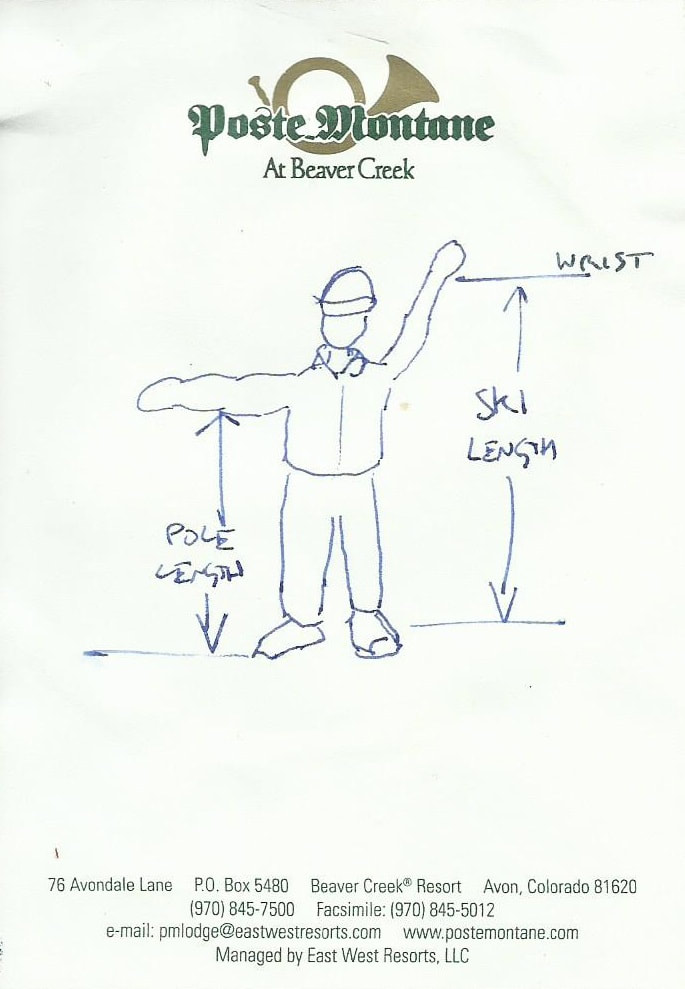

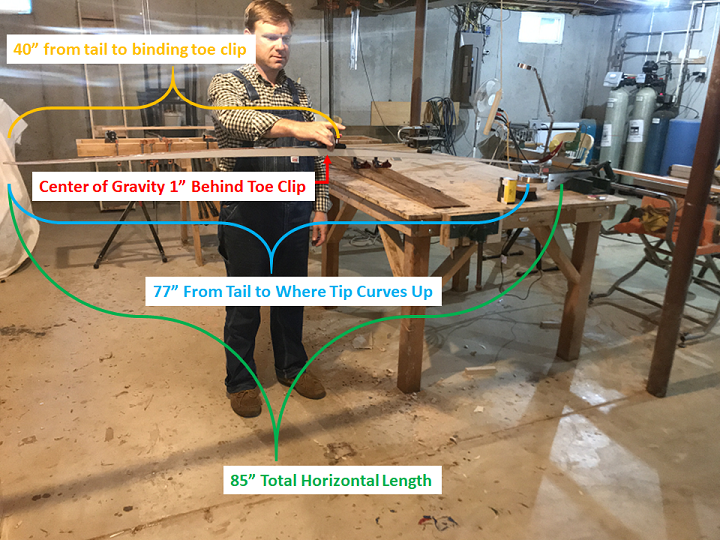

First , I wanted to understand where on cross country skis the bindings are located: at the center of gravity? at the middle of the total length? at the middle of the length that actually touches the ground not including the curved tip?

So I did some analysis of my 1980s vintage modern composite material cross country skis. My findings are in the graphic below.

So I did some analysis of my 1980s vintage modern composite material cross country skis. My findings are in the graphic below.

The pivot point, the toe clip of the binding, on this ski is located slightly forward of the center of gravity. If you raise your foot, the ski behind the clip will be slightly heavier so the tip of the ski will tip up. I think this makes sense, as it will help tip the ski up if you need to raise the ski tip over an obstruction in front of you when skiing.

So, with that, I needed to find the center of gravity of my skis. I did so by picking them up until I found the exact spot where they balanced level. I marked this spot with a pencil.

I decided to mount the 3-pin location of the binding at a position 3/4" (19mm) forward of the center of gravity.

After drilling the holes, I mixed 2-part marine epoxy and filled the holes with the epoxy. This is a viscous epoxy that will fill the wood fibers and seal the holes to protect them from water intrusion.

After filling the holes with epoxy I secured the bindings with the Posi Drive screws from Voile. I used a #3 Philips screwdriver which bit the screw very well. I was not going to go buy a posi drive screw driver, and turned out I did not need one. I tightened the screws very tight, but did not strip them.

Drill 9/64" holes to a controlled depth as noted above for the toe-binding. Fill the holes in the ski for the heel plate with epoxy, so that they are sealed form moisture intrusion. Them screw them down tightly.

Poles....

Completed Traditional Scandinavian Wooden Skis:

Storage of Wooden Cross Country Skis

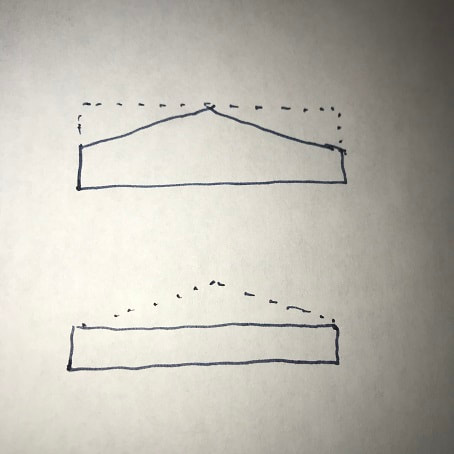

I made some braces to hold the tips and tails of the skis. The gap needs to be accurate, but the exterior shape was just rough cut. In the middle I used a solid wood block. I will store them as shown to help hold the camber in place.

Waxing Solid Wood Skis

After completing the pine-tar application on the skis, which protects them from water intrusion, the ski bottoms should be waxed. Solid wooden skis such as this may be waxed as follows:

1. Wax the entire length two to three times with polar wax. Rub the hard wax onto the ski bottom, then use a cork or synthetic cork to rub the wax into the ski bottom. The pressure and friction of the cork soften and polishes the wax to a glassy surface. This is your glide wax.

2. Apply kick wax, which will grip the snow and help you propel yourself forward, only under your foot. Apply kick-wax which matches the temperature you are skiing in, on the ski bottom, from the boot heel to 8" in front of the boot tip. Rub the wax into the ski base with the cork.

1. Wax the entire length two to three times with polar wax. Rub the hard wax onto the ski bottom, then use a cork or synthetic cork to rub the wax into the ski bottom. The pressure and friction of the cork soften and polishes the wax to a glassy surface. This is your glide wax.

2. Apply kick wax, which will grip the snow and help you propel yourself forward, only under your foot. Apply kick-wax which matches the temperature you are skiing in, on the ski bottom, from the boot heel to 8" in front of the boot tip. Rub the wax into the ski base with the cork.