"3 Bank" simply means that there are three row of keys

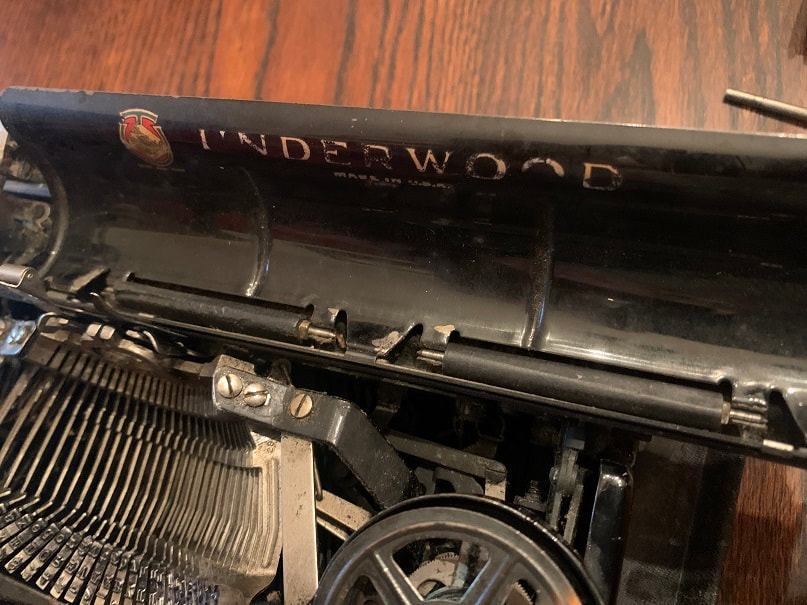

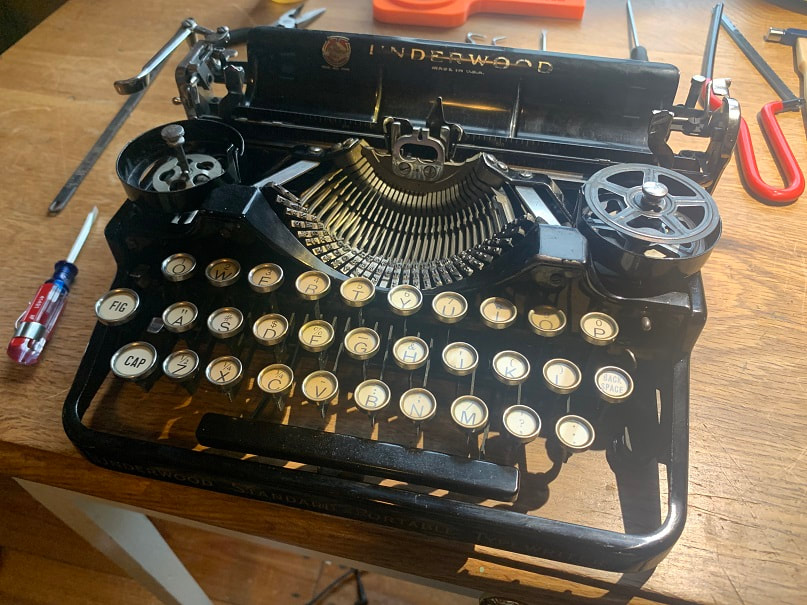

I became interested in these typewriters because of the mechanical genius of their designers, because of their historical importance, and because many books that I like that were written in the 1920s were composed on these exact models of typewriter. Below, I document the repair of two Underwood 3 Bank Typewriters, which each had unique issues, including installation of new platen.

Here I will share what I have learned about Underwood Standard Portable Typewriters; there is much detail below that I think will only be of interest to those that are interested in these particular machines. Also know that I am not a professional, and I expect that some of the methods I use will be proved by my own learning or by others commentary, to be incorrect or inefficient. I am not that old but I am of an age that I used a typewriter in school in the 1980s. I now enjoy typing notes and poetry on these typewriters, and also encouraging others to feed a fresh piece of paper in and type their own words. On these machines, once a letter is typed, there is no going back! These machines are works of human ingenuity, expression, and design, and were used to communicate in a human, pre-digital age. Stay connected humans!, use a typewriter (writes the guy on a internet website, oh the irony). I have a spare Underwood 3 Bank typewriter and might send you parts for Underwood 3 Bank Typewriter from it if you send me a kind note and if the part is still on my spare typewriter; [email protected].

I document below the repair of two Underwood Standard Portable 3 Bank Typewriters from 1923. The first was in very good shape, the second needed a bit more work. I also include photos of replacing worn or missing Underwood Portable Typerwriter case parts.

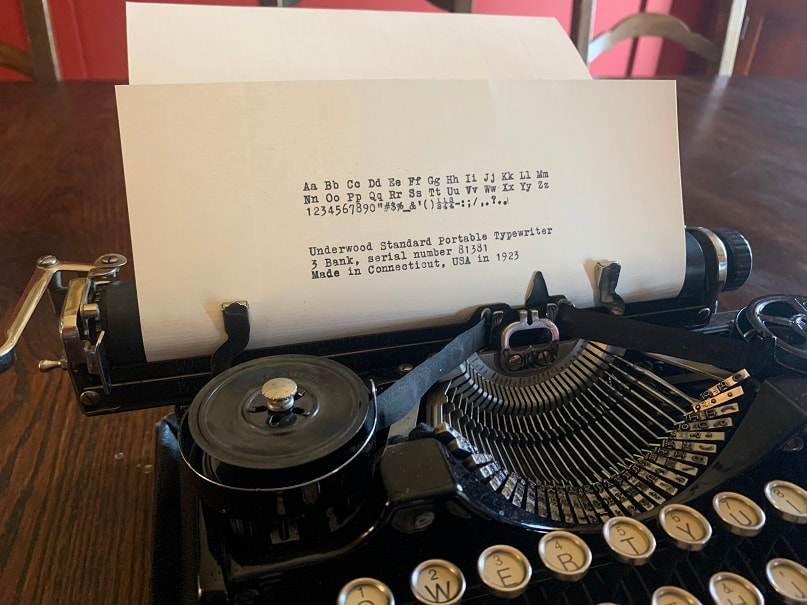

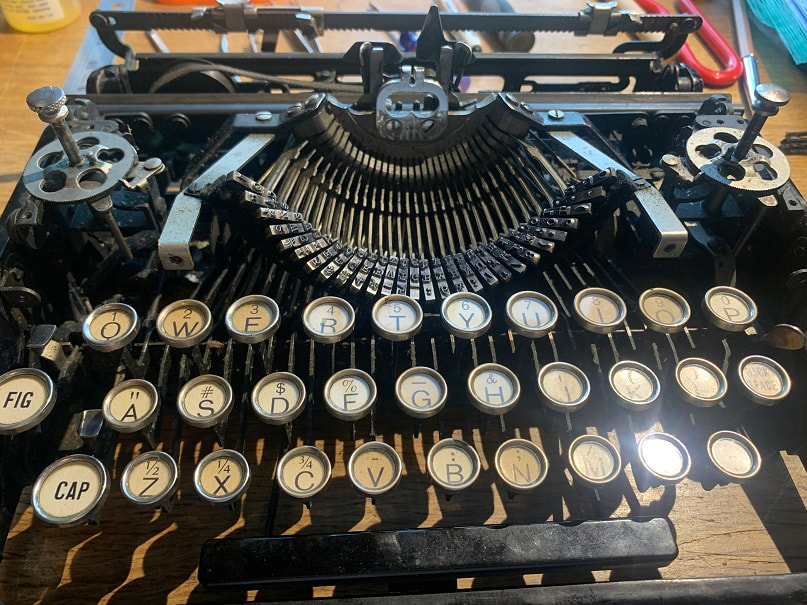

Underwood Standard Portable 3 Bank Typewriter sn 81381:

I bought this typewriter, serial number 81381 built in May/June 1923, and it was in great shape, but needed the followings repairs:

Items needing repair:

It was missing parts, so I bought an identical typewriter, sn92451 and stole parts off to make this typewriter whole. Documented further down this page is my more extensive repair of sn92451.

Items needing repair:

- The bell didn't work

- There were no paper supports.

- Rubber feet were missing and replaced with foam

- Rubber case feet missing and replaced with foam

- Remove and install new rubber platen

It was missing parts, so I bought an identical typewriter, sn92451 and stole parts off to make this typewriter whole. Documented further down this page is my more extensive repair of sn92451.

Removing Underwood Portable from the case board

The front of the typewriter is held down with two screws. The back of the type writer is held down by brackets that hold the rear feet. To remove the typewriter from the case board, remove the two screws that hold the front down, then, keeping the typewriter flat down on the case, slide the typewriter forward to pull the rear feet out of the brackets that hold them.

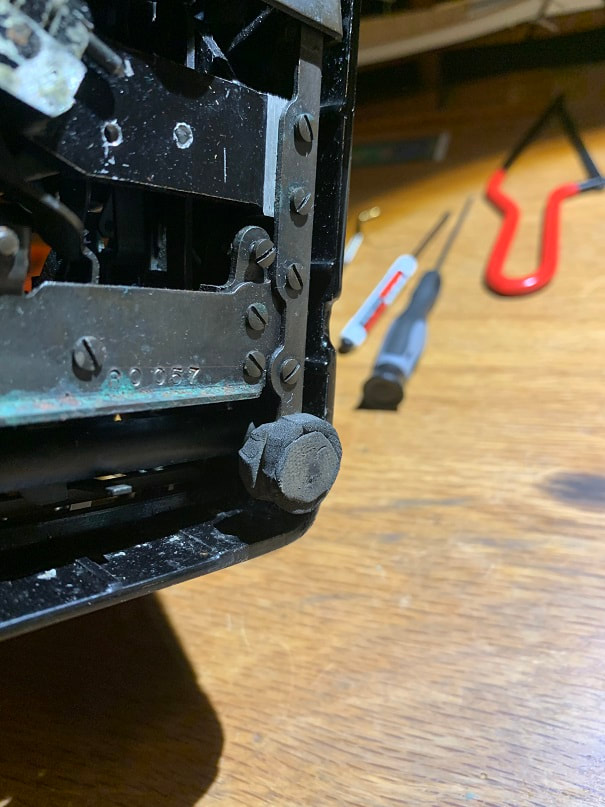

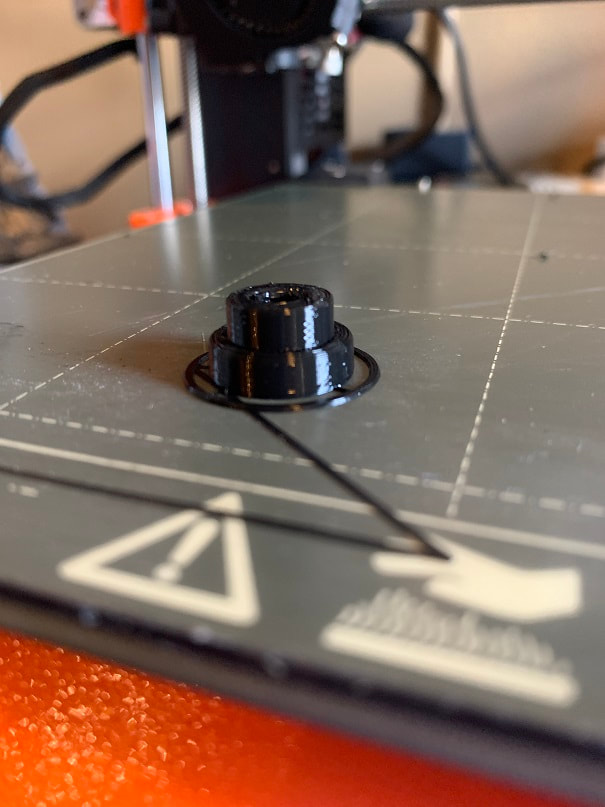

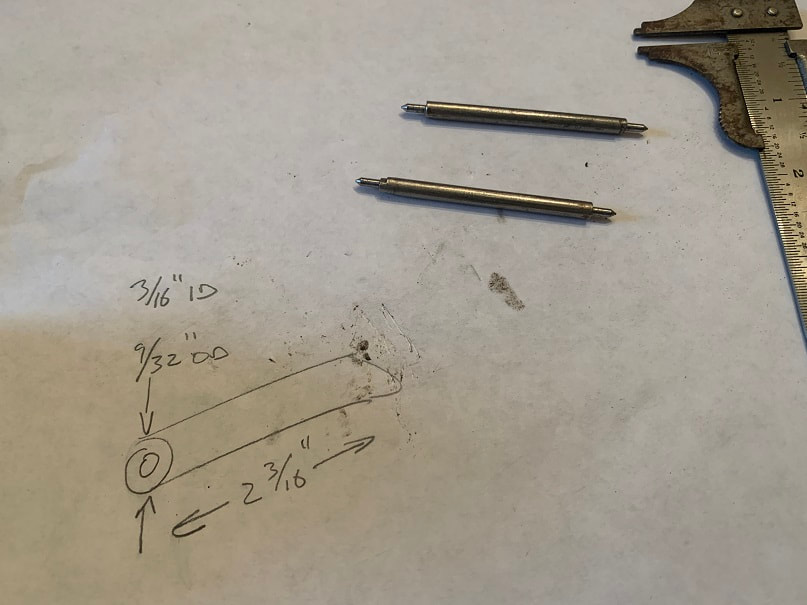

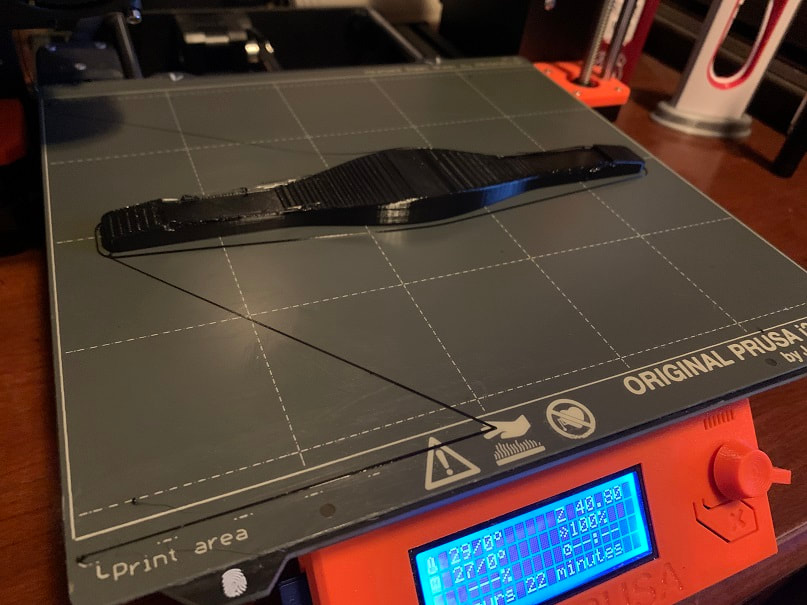

Underwood Standard Portable 3 Bank Foot reproduction

I 3D printed new typewriter feet to replace to worn and cracked feet on both typewriters above. Here's how I did it. The rubber on these antiques gets hard and cracks over time. The feet on both of my typewriters were cracked and defective. I drew new feet on Fusion 360 and went through about five design iterations, making small adjustments to the dimensions each time, until the feet came out perfectly on my 3D printer. I first printed these in 60A Durometer TPU material but it was too soft. I tried 30D durometer TPE and it worked great. Here are some photos of the new feet, along with a photo of the old foot that I used as a pattern for the design. I printed these on my Prusa i3MK3S 3D Printer.

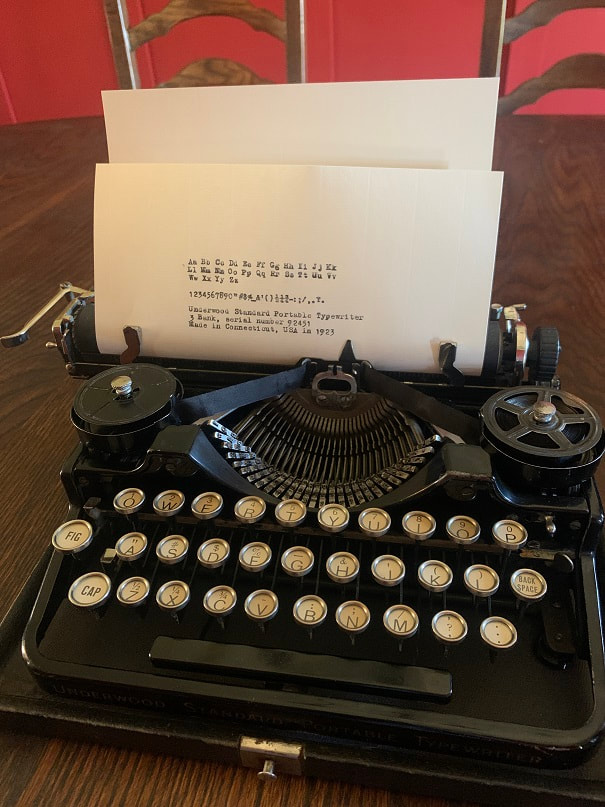

Complete and fully functioning Underwood Standard Portable 3 Bank Typewriter sn81381:

Here is a Link to a website that lists these typewriters by serial number and year of manufacture.

and a great article on the design history of the Underwood Standard Portable 3 Bank Typewriter:

At the bottom of this page I share case restoration, including make new case feet and handles.

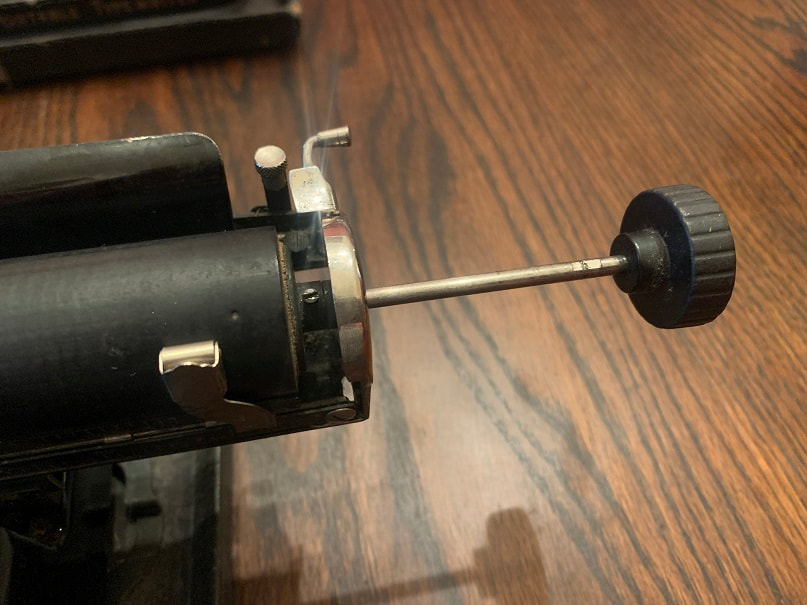

The platen on the typewriter above had become too hard. Click here to visit my page on making a new platen.

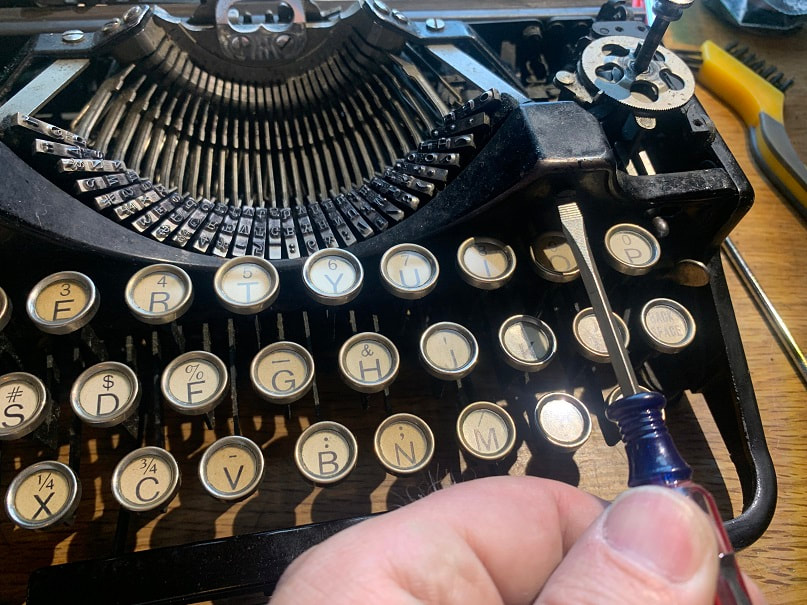

Repairing Underwood Standard Portable Typewriter Serial Number 92451

Missing parts and functions that don't work on this typewriter:

- Bell is missing

- Paper supports are missing (took them off to finish another typewriter)

- Line space lever does not engage sprocket and does not advance the cylinder

- Rotating the cylinder knob does not advance paper; the cylinder does not grip paper

- Keys stick

- The left steel ribbon spool is gone and replaced with a paper one

- Fig and Cap keys raise the carriage but the carriage stays up and does not return down

- Feet are cracked and broken

A note on solvents and lubricants:

- Pure Mineral Spirits work well to clean up parts but be careful not to over scrub or damage parts in an effort to clean them

- After the parts are nice and clean there may be a temptation to lube 'em up with various oils. Please note that in my opinion liquid oils in many applications, especially external exposed surface applications, will attract dust and cause dust to stick to the oil and gum things up more than if the oil had never been applied. Please keep this in mind.

Disassembling this machine is like a puzzle and I don't have a manual so I may not have done this the right way, but here is how I disassembled this typewriter.

The typewriter seems to be in good working order but needs new rubber and there is so much gunk and dust in all the parts, that it must be disassembled, cleaned, and reassembled; with missing parts replaced.

Now, onto the photo log of how I am restoring this typewriter.

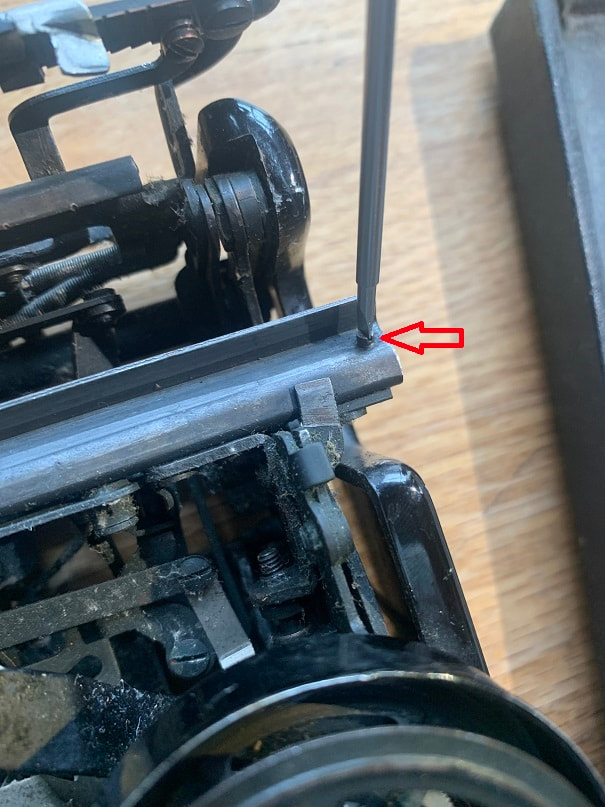

Removing the carriage from the Underwood Portable 3 Bank

With the nut removed I carefully lifted the metal fitting at the end of the fabric draw- strap off of the stud, and I carefully led the strap backwards rather than letting it fly. It got caught up byt he bearing wheel as shown in this picture, but I was able to navigate it around this wheel, and then the spring-strap was totally out of the picture.

At this point, I tried to completely slide the carriage off the typewriter to the right, but the left side frame of the cylinder and the line space level and the thumb piece all interfered with the type guide and ribbon guides which prevented the carriage from being removed. Thus , I set out to remove the frame and hardware from the left side of the cylinder carriage.

At this point I was able to pull the carriage assembly to the left, off of the typewriter. It took some jostling around a metal tab on the back and the central bearing wheel, but it came out.

Removing the cylinder carriage of the Underwood Portable 3 Bank Typewriter, unveils yet another very reliable and high quality device; the bearing wheel carriage that ensures 100years of smooth rolling! This is the correct orientation in the raceway. In this photo you can see all the dust and gunk that is keeping the machine from running smoothly.

Here is the face plate after initial cleaning. There is a felt strip on the bottom of it that cushions the key levers, and the felt was coming loose. I superglued it back in place with a very very thin layer of thick-viscosity superglue. Thin viscosity superglue would wick quickly through the thickness of felt, making it hard, so I would stay away from thin viscosity superglue for this.

With the parts removed so far, I can now see the internal linkages and springs of this Underwood Portable 3 Bank. My hope is to get to a point where I can clean up all the linkages without having to completely disassemble the entire typewriter. I am going to make an effort now to clean and de-gunk the working of this typewriter without any further disassembly.

The first cleaning step I took was to blast it out thoroughly with compressed air. I used the compressor that I use for my nail gun, it's a decent size compressor not a little benchtop compressor. I had it at 120psi and blasted the heck out of all the linkages.

Turns out this typewriter was in good shape and needed dust and gunk removal but did not have any rusted or stuck parts. Had the machine been in worse shape I would have needed to further disassemble , and wash and soak the components.

With the cleaning done and linkages all moving nicely. I re-assembled the typewriter in the reverse sequence vs disassembly.

The above photo is of the re-assembled Underwood Portable 3 Bank. At this point I pressed the keys and felt all the nice linkages and was pleased, and then I optimistically pressed the FIG button and the carriage lifted, and to my dismay, it stayed stuck in the raised position. It is supposed to return back down when the fig key is lifted. I will say that a big part of the fun of this is the puzzle of troubleshooting the mechanisms so I was happy to dive back into the machine. I found that the big torsion spring visible from the bottom appeared to be providing upward force to assist the lifting of the carriage when pressing the fig and caps keys. If the force of this spring is too high then I thought gravity might not be able to overcome the spring force in order to return the carriage back down.

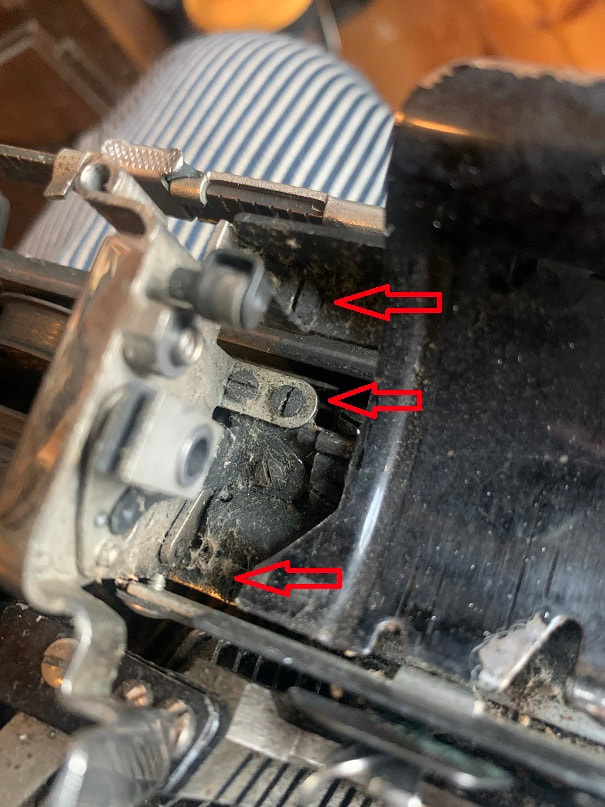

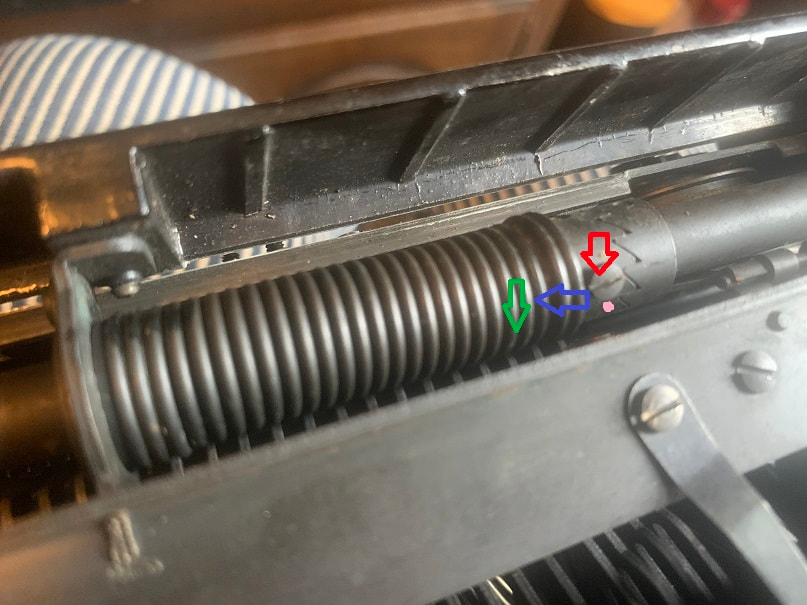

Do this at your own risk and BE CAREFUL. This torsion spring is like a mini-garage door spring and when the force is unleashed it can run away from you. I reduced the spring force by loosing up the screw RED ARROW only unscrew it enough to loosen it a bit, but leave it as fully threaded in as you can. Then

I put a flathead screwdriver under screw head (PINK DOT) and held this tight to keep the spring from unwinding too fast. With another flathead screwdriver push the screwhead to the left (Blue Arrow) do disengage the teeth. I loosened it by three teeth (screw head moved in direction of green arrow), and retightened it. It worked perfectly!!!!! The FIG and CAPs keys now lift the carriage perfectly and it comes promptly and smoothly back down.

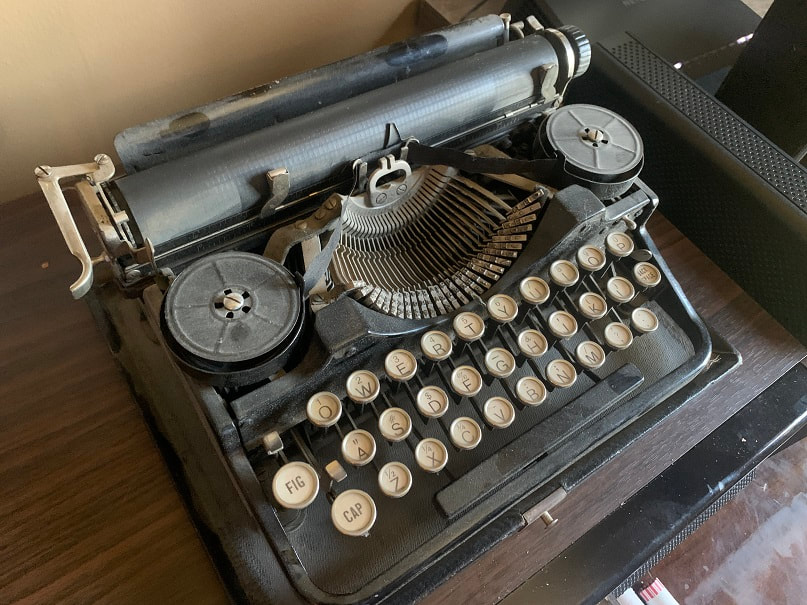

At this point I bought a parts machine to take parts from. This is sn82121; I bought it at a charity auction, it doesn't work but it has the parts we need. Someone also painted the frame black at somepoint, so I can see all the original decals painted over. I do not intend to fix this one, I will use it for parts. IT's got great keys and many perfect parts on it.

Finally, I reinstalled the platen and was very pleased that the line space lever works perfectly in both the single space and double space positions. I installed the paper holders from the parts machine, and I installed a new ribbon. She's done!!!

Underwood Standard Portable 3 Bank Typewriter Case: Restoration

The Underwood Portable 3 Bank is screwed down to the base of the case, and is typed-upon while remaining screwed down to the case. These are rubber feet on the typewriter that cushion it from the case base (see above feet) and there are rubber feet on the bottom of the case base that cushion it from whatever surface one sets it on.

Typewriter Case Feet:

Often the case handles are weak, broken, or missing and the feet on the bottom of the case may be broken or missing. I had one case with existing case-feet. I measured these and made drawings, and printed replacement case feet for the cases that I had that were missing feet.

Typewriter Case Feet:

Often the case handles are weak, broken, or missing and the feet on the bottom of the case may be broken or missing. I had one case with existing case-feet. I measured these and made drawings, and printed replacement case feet for the cases that I had that were missing feet.

This case had large foam pads stuck to the bottom, which worked, but which were not to original spec. Here are new 3D printed replacement Underwood Portable 3 Bank Typewriter case foot pad installed into the case base (my only issue with this is that I would prefer a slotted head screw instead of the phillips!....my hardware store didn't have a slotted screw in the size I needed. Once I find the slotted head stainless screw in this size, I will redo this.)

Handle for Underwood Portable 3 Bank Typewriter Case:

Of the 3 Underwood Portable 3 Banks that I bought, one was without a handle, one had a good leather handle, and one had a leather handle so brittle that I would never use it to lift the typewriter. In general, I would say don't lift an antique typewriter case up by the handle unless you are absolutely sure its strong and sound. I designed a replacement handle on Fusion 360 and printed it in 30D Durometer flexible material. It is thick and very very strong. The steel straps that are secured to the case for the handle cannot be removed so I designed the handle with barbs at the ends that once pushed through the strap, cannot be pulled back out.