Build log of the Steam Launch "Alexandra", a fully functioning steam engine-powered boat model.

I became interested in how steam-engines worked and set out to build a model steam engine and a boat that the engine could power. I decided on a model of a classic English steam launch built in 1900; the model is called "Alexandra" and the kit comes from the German company, Krick; it is 35.5" long. I will make some modifications and customizations to the model which I will note during construction. Here are some photo's of actual steam launches, along with the stock photo from Krick, of the Alexandra.

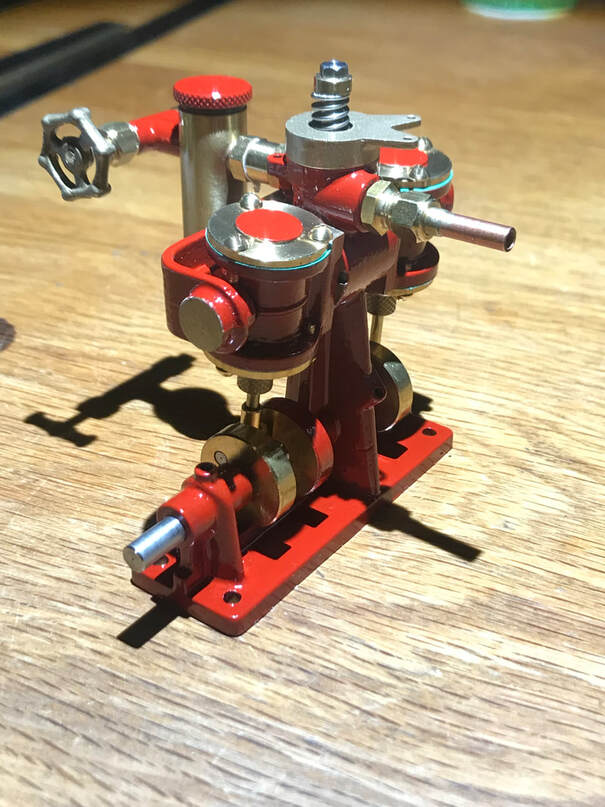

I selected the Miniature Steam Models (MSM) "Clyde" Steam Engine to power my Alexandra.

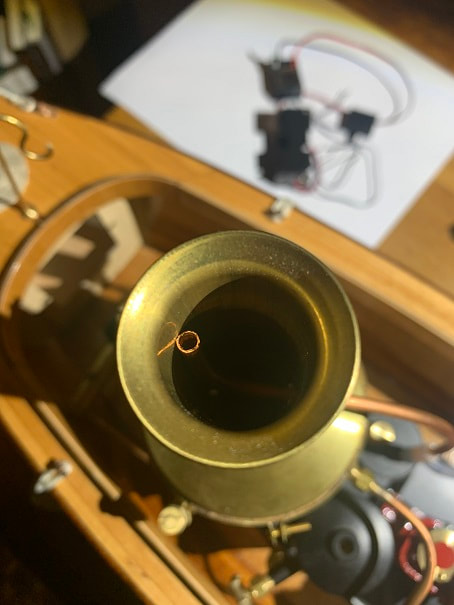

MSM is in Melbourne, Australia and I selected their "Clyde" twin cylinder oscillating steam engine to power the Alexandra. I bought the engine in pieces so that I could learn better how they go together and how they work. You will need to know the dimensions and mounting points for your engine, as you build the boat, so I decided to build the steam plant during the first stage of boat construction. You wouldn't want to glue down the sole without first knowing the steam plant mounting hole locations. It was a very enjoyable assembly process. Here is a link to the page where I detail the assembly of the engine:

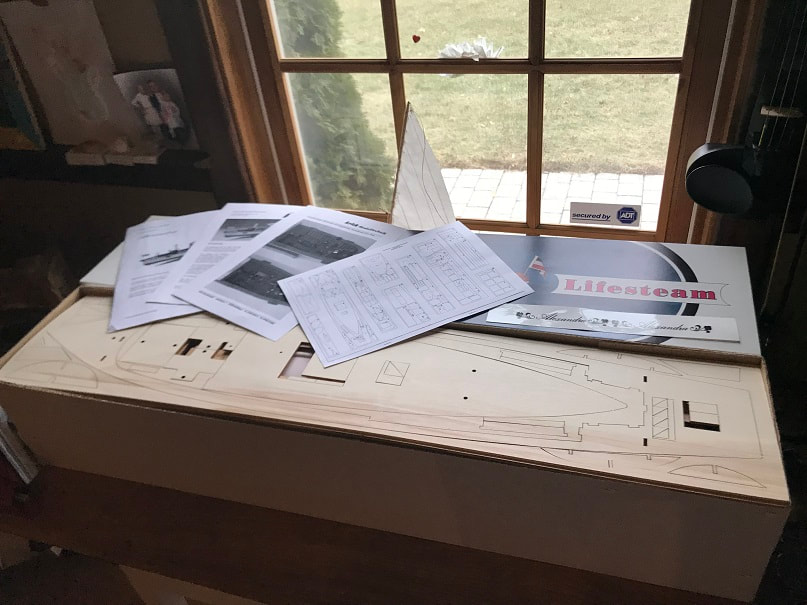

Instruction Book for the Krick Alexandra:

The English translation of the manual is missing illustrated figures along with descriptions of the first pages of part numbers. I edited the manual to add the illustrations from the German manual and also translated the parts lists to complete the English manual. Here is the updated set of instructions:

| krick_alexandra_revised_english_instructions.pdf | |

| File Size: | 5899 kb |

| File Type: | |

Building the model:

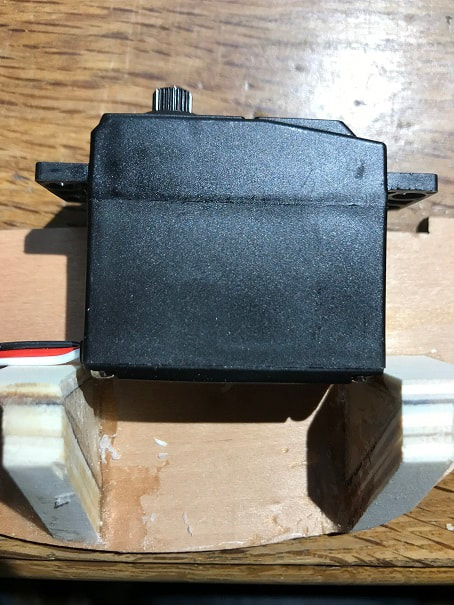

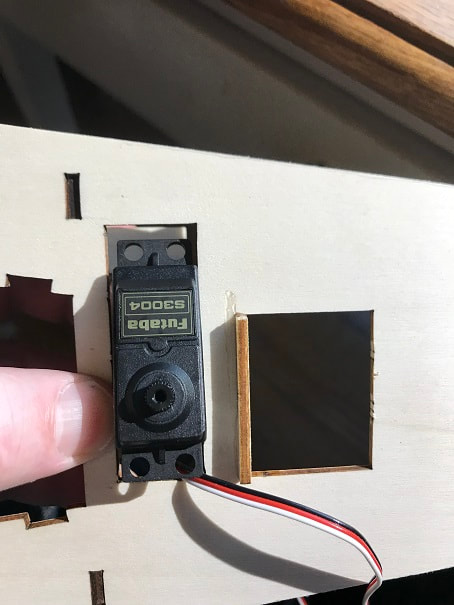

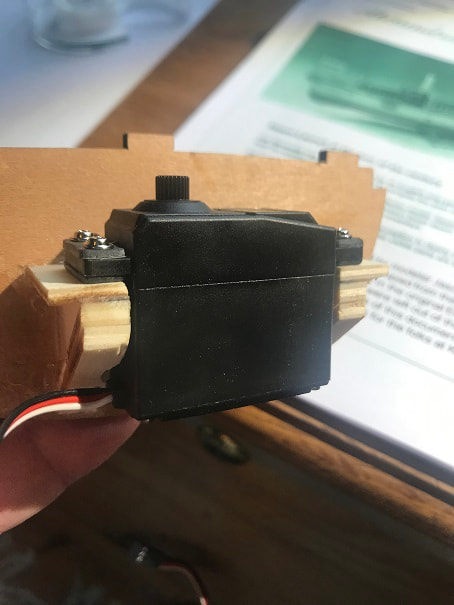

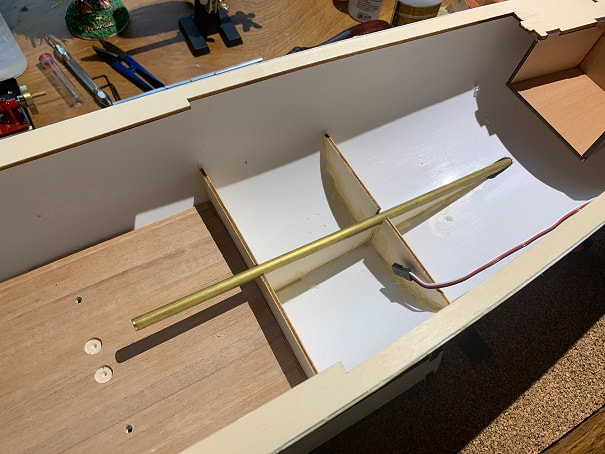

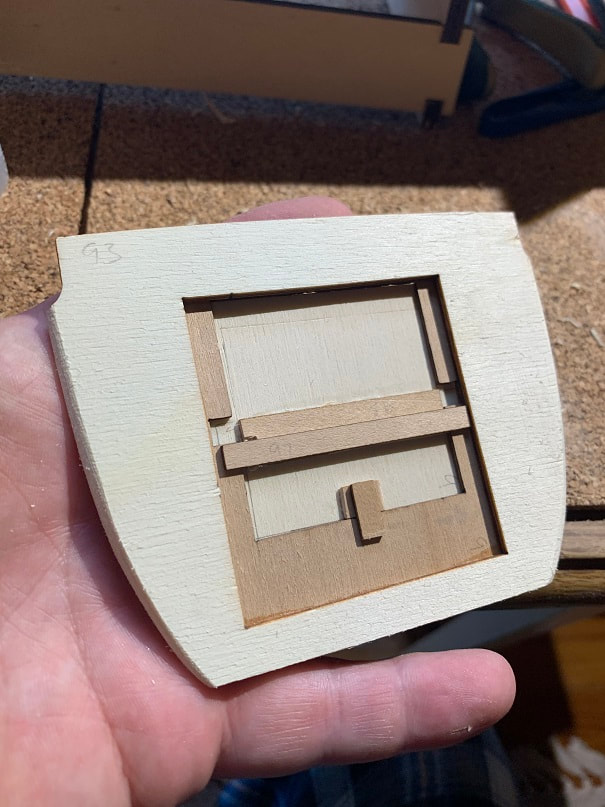

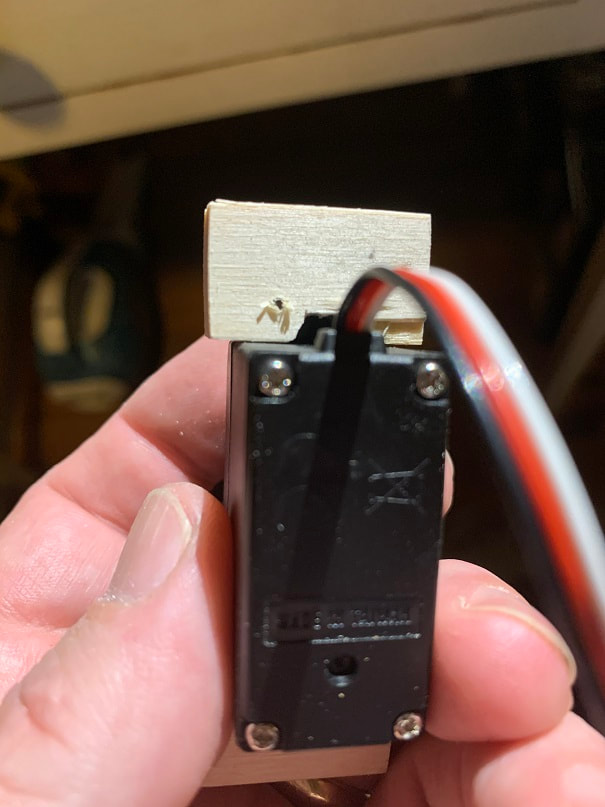

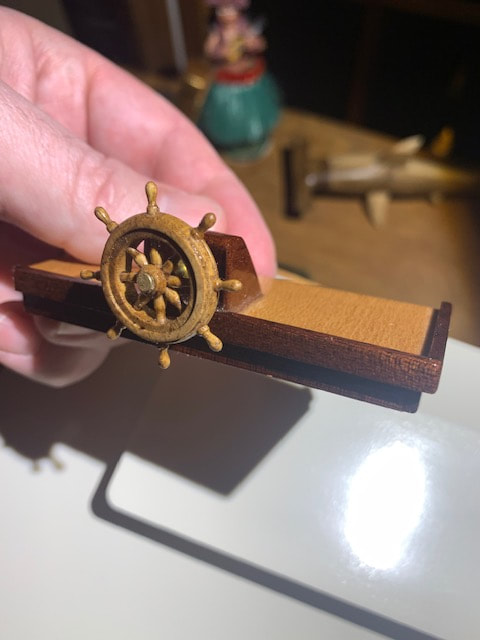

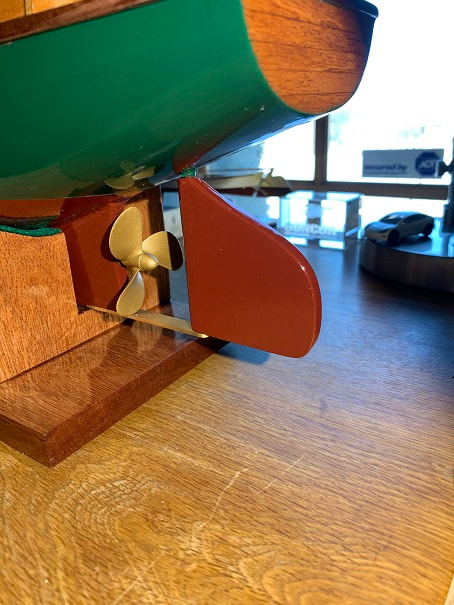

As with the steam-engine, I would recommend acquiring your electrical components in advance of building the model, this way you can build the model such that they will fit in the model. This is a view of the rudder steering servo which is mounted in the stern. I selected two Futaba S3004 servos for this model. One for the rudder, and one for the steam engine control.

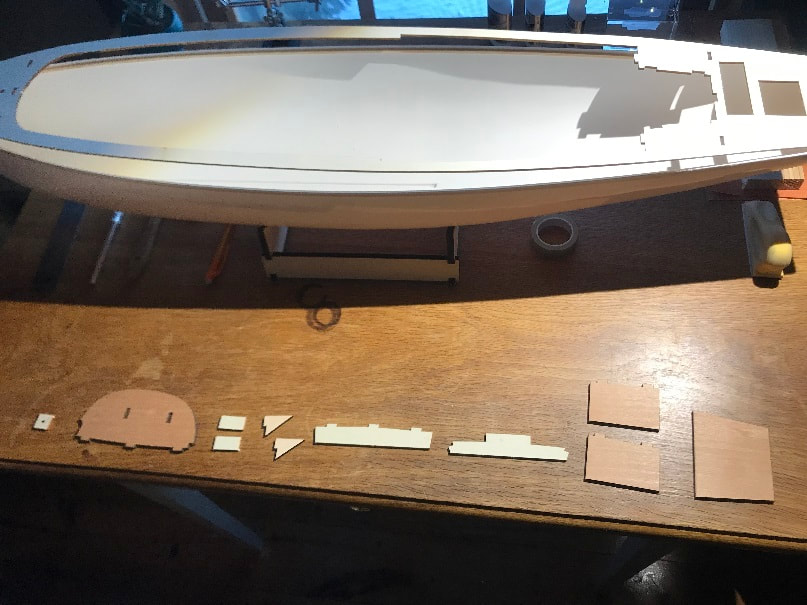

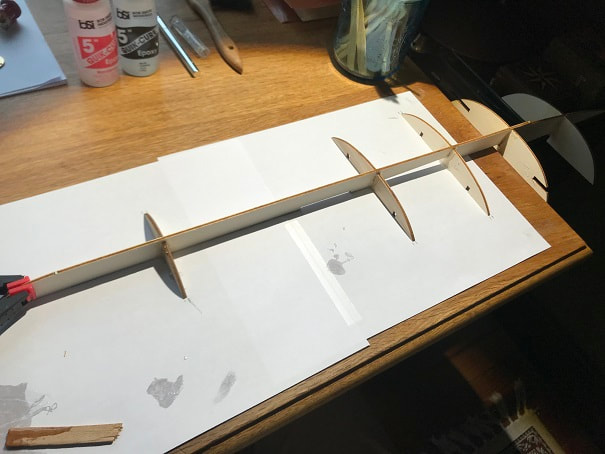

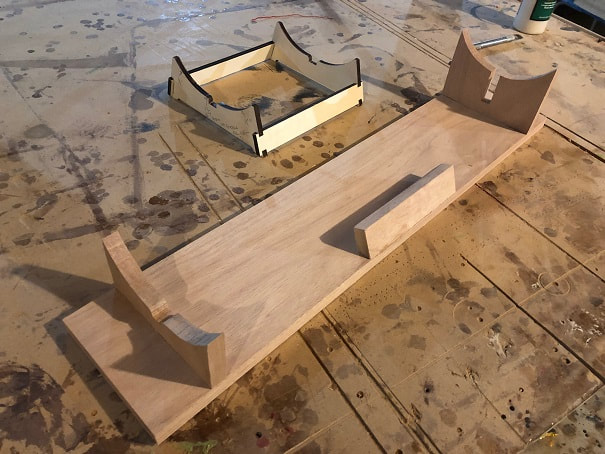

Steam plant mounting holes drilled. I wish I would have taken a picture of the underside. I added wooden backing plates to increase thickness at the mounting bolt locations, and epoxied drive-nuts into the bottom of the sole. The drilled reccesses are used where screwheads protrude from the bottom of the steam plant base plate.

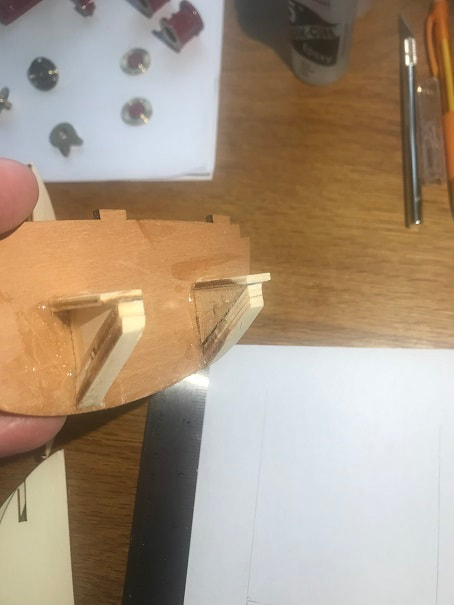

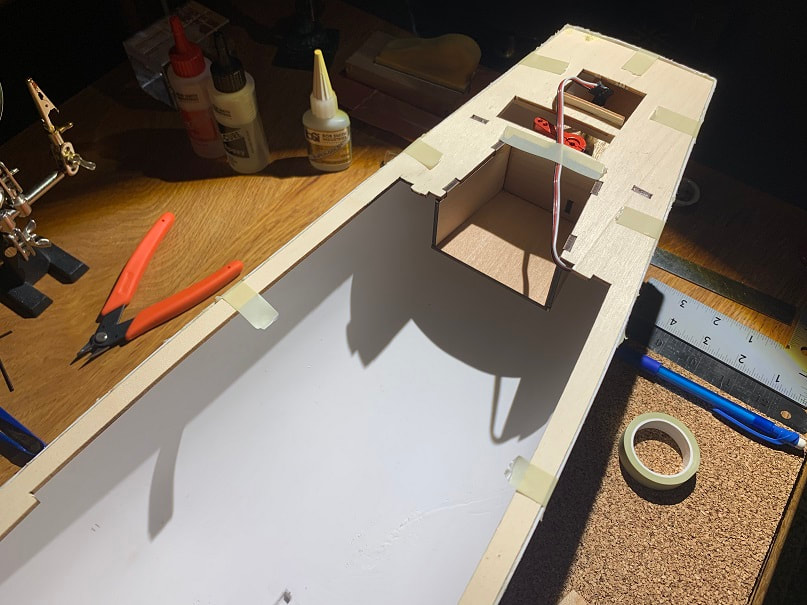

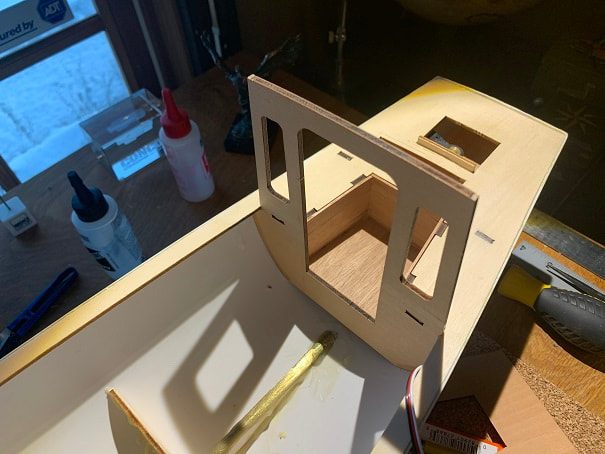

Starting construction of the cabin. I trimmed the edges of the sole here to fit the hull, but I made an error and did the trimming on the topside of the sole. This part is not symetrical, it has slots cut in it for parts 69 and 70 near the door. As can be seen in this photo, I therefore needed to make some parts to fit that area. The outcome is the same, so luckily my error was not unrecoverable.

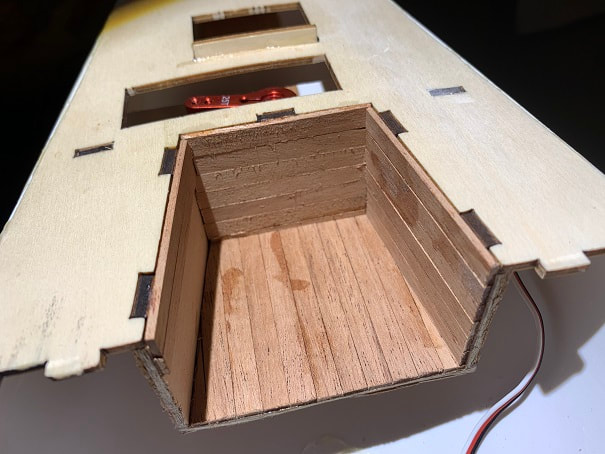

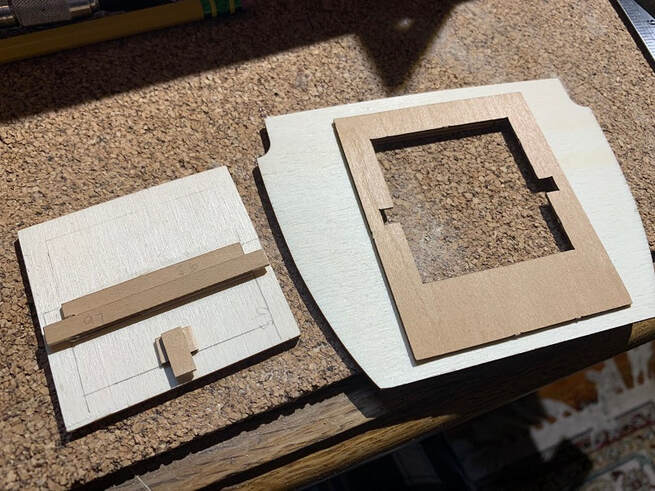

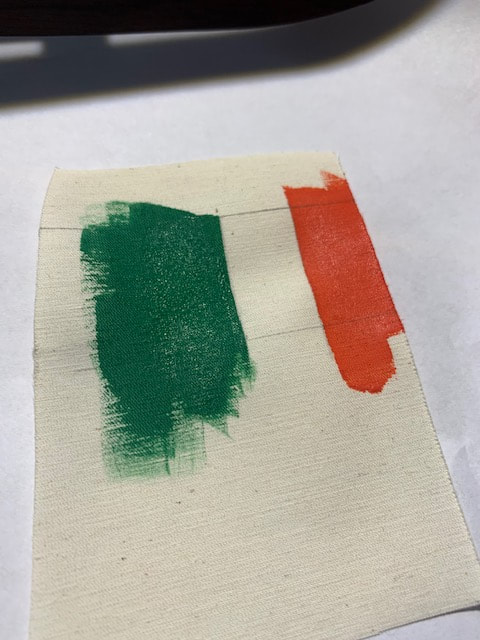

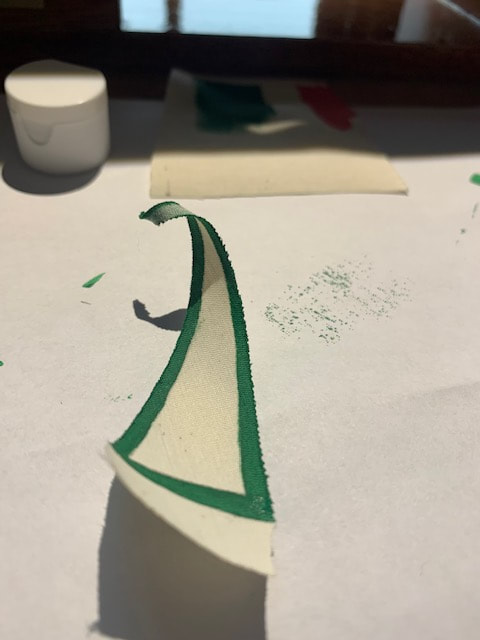

The Krick Alexandra is a model with a plastic hull and primarily plywood parts. In many cases there are large flat sections of plywood that would certainly look nice if just left as-is in the model, but I think the model is nicely enhanced by adding planking and trim in many areas, beyond what is called for in the plans. Using trim to cover exposed tenons and exposed plywood end-grains is a nice decision I think. Here is the forward bulkhead hatch with hardwood trim around the edges and hardwood planking on the face.

I measured exactly where the control rod will need to exit the front of the cabin to align properly with the valve on the steam engine, and I marked this location on the inside of the front cabin wall. I installed the servo so that the servo horn will align with this spot. Servo brackets epoxied in place.

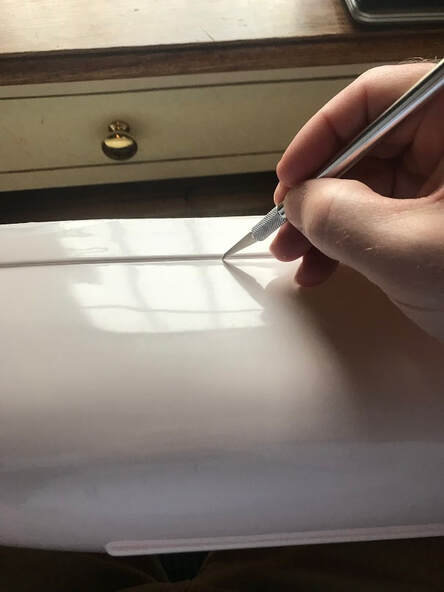

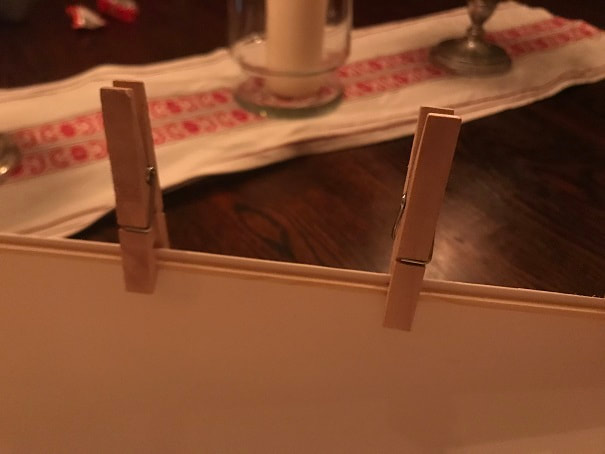

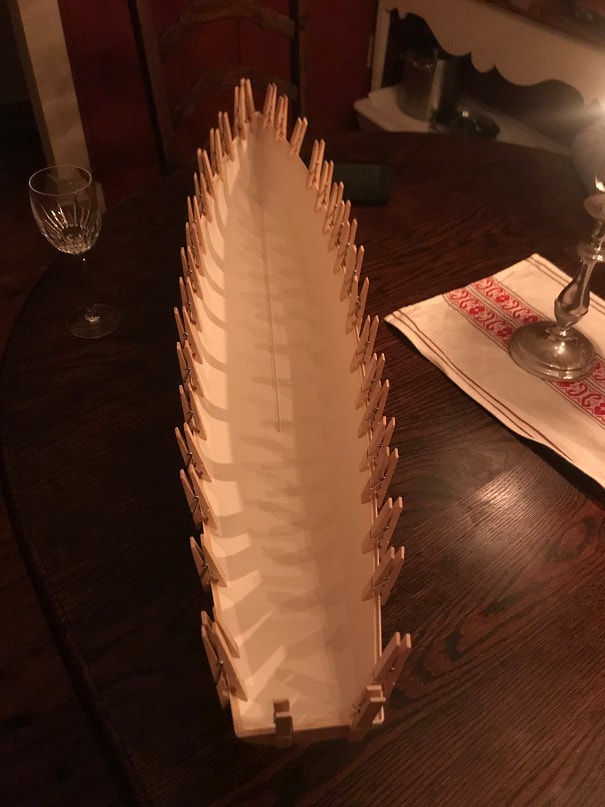

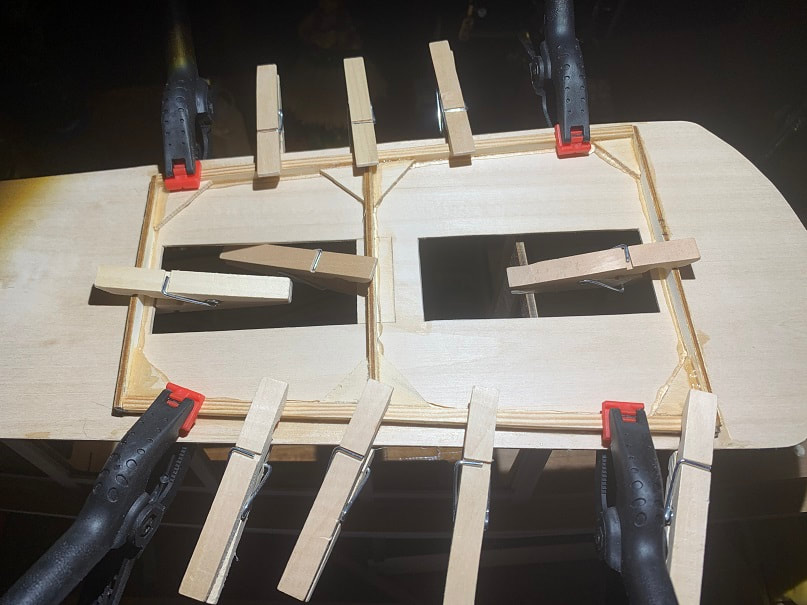

Here I am working on installing the coaming. The coaming is made from two layers of reinforced plywood. Here you can see the first layer of plywood installed. I was able to bend the front curved section without steaming it. NOTE: the curved plywood parts meant for the fore coaming pieces, were wider than the adjacent longitudinal coaming boards in the kit. I cut them down so that the long coaming along the port and starboard side matched the nice curved coaming at the fore of the open bow area.

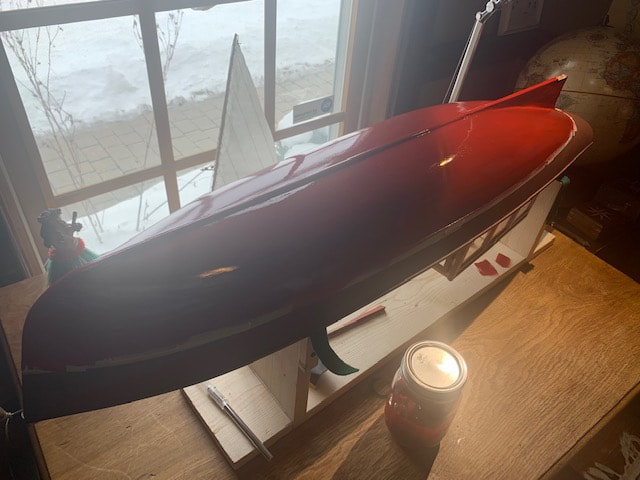

Setting the ballast and finishing and firing up the steam plant

The launch hull and trim is all done, but the ballast still needs to be set, the radio control needs to be completed, and the final steam fittings and relief valves need to be set and finished.