Humans really began understanding how to harness the power of steam in the early 1700's and by the end of the 1800's steam powered locomotives were driving economic expansion across continents and steam engines were replacing sails on the high seas. Of course steam engines were eventually replaced by internal combustion engines, but in it's heyday, steam powered the world. Here in Wisconsin USA, my family and I took a trip last year on the last big coal fired steamship plying the Great Lakes, The SS Badger, which crosses Lake Michigan every day. Standing on the aft deck one can smell the coal burning and feel the ash falling. From an environmental point of view it's good humans came up with cleaner engines, and we need to come up with new better ones still, but from a historical perspective, I love these technologies.

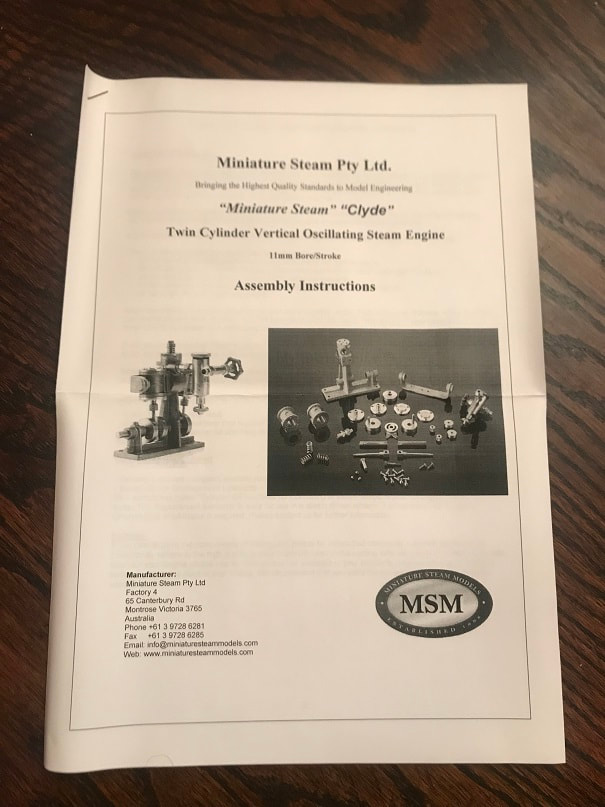

I am building a model steam launch from a kit. She is called the "Alexandra" by Krick models in Germany. Shew will be fitted with a complete functioning steam engine. Here are the photo's of the assembly of the "Clyde" Oscillating Steam engine, made by Miniature Steam Models in Melbourne, Australia, and assembled by myself in Wisconsin USA, and which will be installed in my model of the "Alexandra".

Oscillating steam engines feature engine cylinders that rotate or "oscillate" as the engine turns.

https://en.wikipedia.org/wiki/Oscillating_cylinder_steam_engine

There are many types of steam engines to learn about, and many of those feature cylinders that do not oscillate at all. Have fun with the research!

https://en.wikipedia.org/wiki/Oscillating_cylinder_steam_engine

There are many types of steam engines to learn about, and many of those feature cylinders that do not oscillate at all. Have fun with the research!

Assembling the Clyde Oscillating Steam Engine

The "Clyde" can be purchased assembled or as a kit. MSM's website is www.miniaturesteammodels.com The kit is very easy to assemble and does not require any manufacturing or modification of parts. It's a quick project with nice instructions from MSM. The parts fit great. My goal in buying a kit was to try to better understand how the parts work together and how the engine works.

Summary video of the assembly of the Miniature Steam Models

"Clyde" Steam Engine:

I decided to paint my MSM Clyde engine. I picked a color scheme and picked parts of the engine that I would paint, and some parts that I would leave unpainted. The recommendation in the manual was to use self-etching primer on the bronze, to ensure a good paint bond, so here is the self-etching primer. I did 2 coats by hand with a small brush. Do not paint any bearing surfaces, mating surfaces, valve ports, or internal surfaces or internal parts.

My paint scheme includes many bright metal area which are left unpainted. My experience with brass and bronze is that they will tarnish quickly if left coated, and I didn't know how I would ever polish some of these small shapes and surfaces, so I decided to lacquer the exposed surfaces, EXCEPT those that will be bearing or working surfaces such as piston rods, shafts, and the mating surfaces between any moving parts....those I left unfinished and will lubricate.

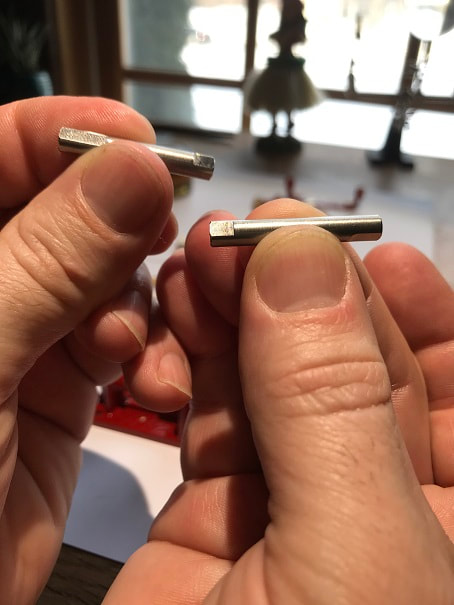

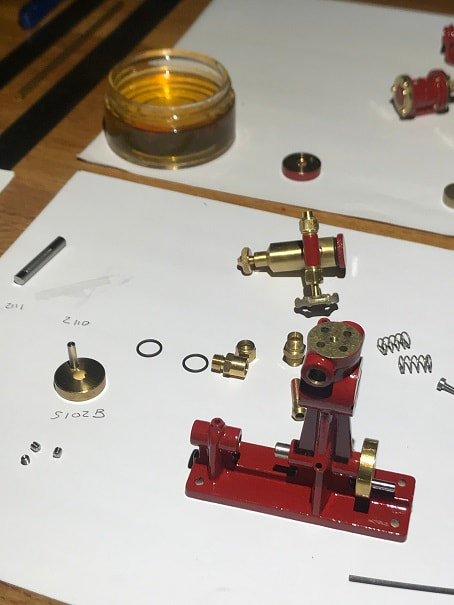

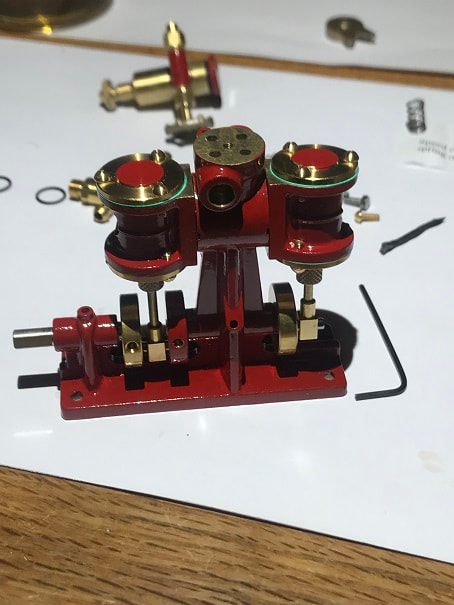

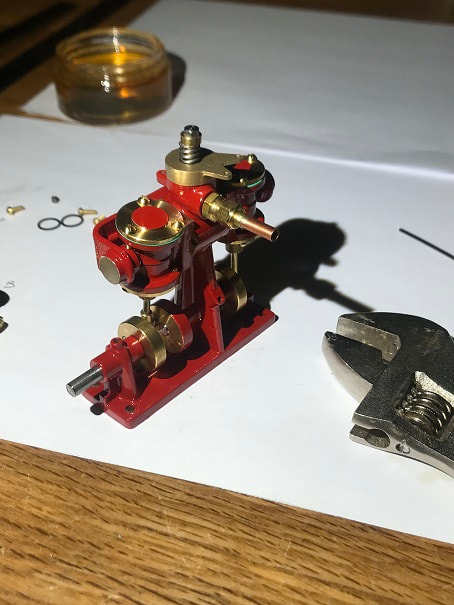

Complete MSM Clyde Steam Engine parts layout. I have painted what I'm going to paint, and am ready for assembly. Piston rods are now included in the photo (on the left). I have 10W30 motor oil ready and special 460 steam cylinder oil. I used the 10W30 on shafts and bearing surfaces, and I used the cylinder oil for the piston rod OD and the piston OD and the cylinder ID.

Piston rod has the gland nut with gland packing in it, threaded onto the bottom cap of the cylinder. The gasket that seals the bottom cap to the cylinder is shown. The piston with O-ring has been threaded onto the piston rod. Lubricate the o-ring with some cylinder lube before stretching it onto the piston, you don't want to tear the O ring. Lightly lubricate the piston rod and make sure that the gland packing is sealing the circumference of the piston rod...but also make sure it is not so tight as to create too much friction on the rod.

Repeat the above steps to assemble the 2nd cylinder/piston assembly.

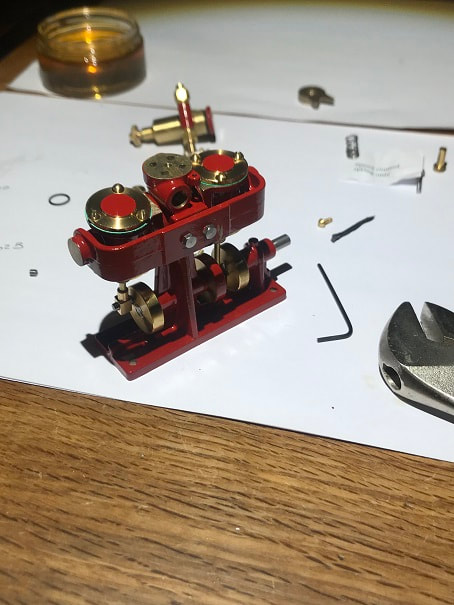

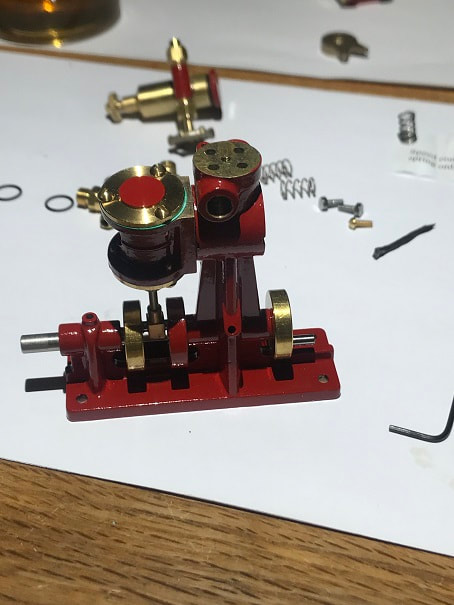

Lightly lubricate the flywheel pins and crankshafts with oil (I used 10W30). Install the big end of the piston rod on one of the cylinder assemblies (doesn't matter which cylinder assembly, they are both the same). Then place the center flywheel, the one with no pin in it, on the long flywheel pin, over the big end of the piston rod. Back out the crankshaft that you have in the mainbearing so that it is not protruding from the mainbearing. Set your assembly of two flywheels and piston end in the space between the two trunk bearings. Line up the center holes and push the crankshaft from the mainbearing into the center hole in the flywheel. Take the remaining crankshaft and insert it through the smaller bearing in the trunk into the other remainining flywheel centerhole. Rotate the flywheels and shafts to align the flats with the set screw holes and tighten down the set screws on the flats. Then lift up the cylinder assembly, lightly lubricate the flat surface and pin where it will fit into the trunk, and then gently put it into position on the trunk, inserting the pin into the hole in the side of the trunk.

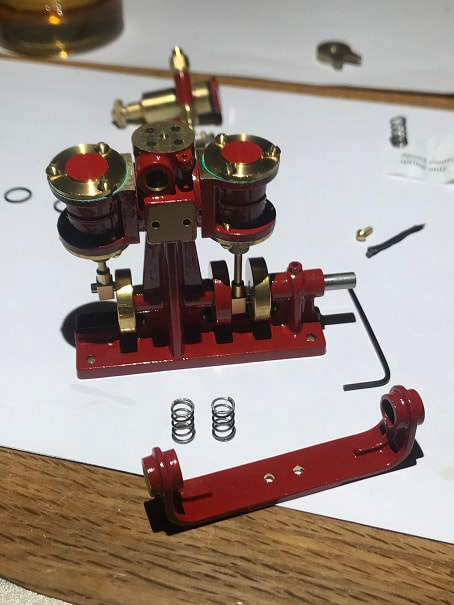

Set both springs into the cups at the ends of the holding bracket. Set one spring in place in the bracket on the end of one cylinder and compress it as far as you can an to make it possible to also compress the other spring onto the opposite cylinder. I used a small flat screwdriver to help compress in the 2nd spring into place on the opposite cylinder. There are small circular pockets on the outside of the cylinders to accommodate the springs. Secure the bracket to the trunk with the two stainless steel screws as shown.

Slowly and gently rotate the crankshaft and ensure smooth motion of all the parts. If there is any binding. Disassemble and retrace your steps and find the issue....do not force it, you could break it.

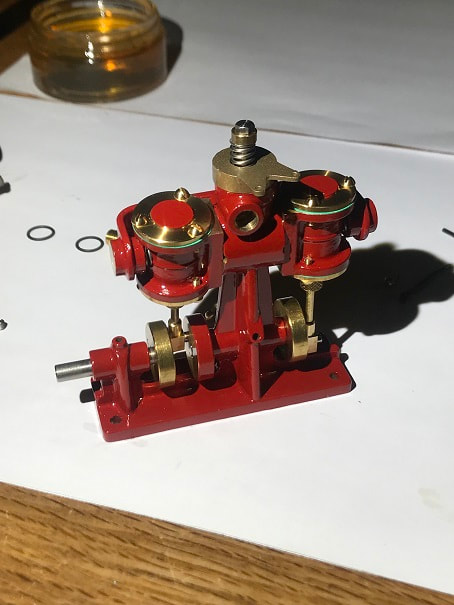

These are the exhaust fittings. Use thread tape and install the fittings into the engine. The exhaust can be fitted to either port in the side of the engine, depending on the layout of your engine installation. Either port can be the steam inlet or steam exhaust, the reversing control will switch the steam direction flow either way.

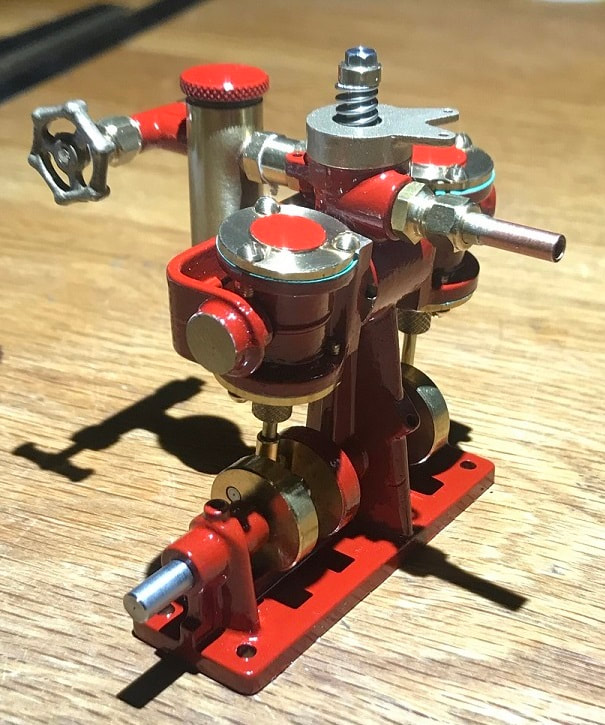

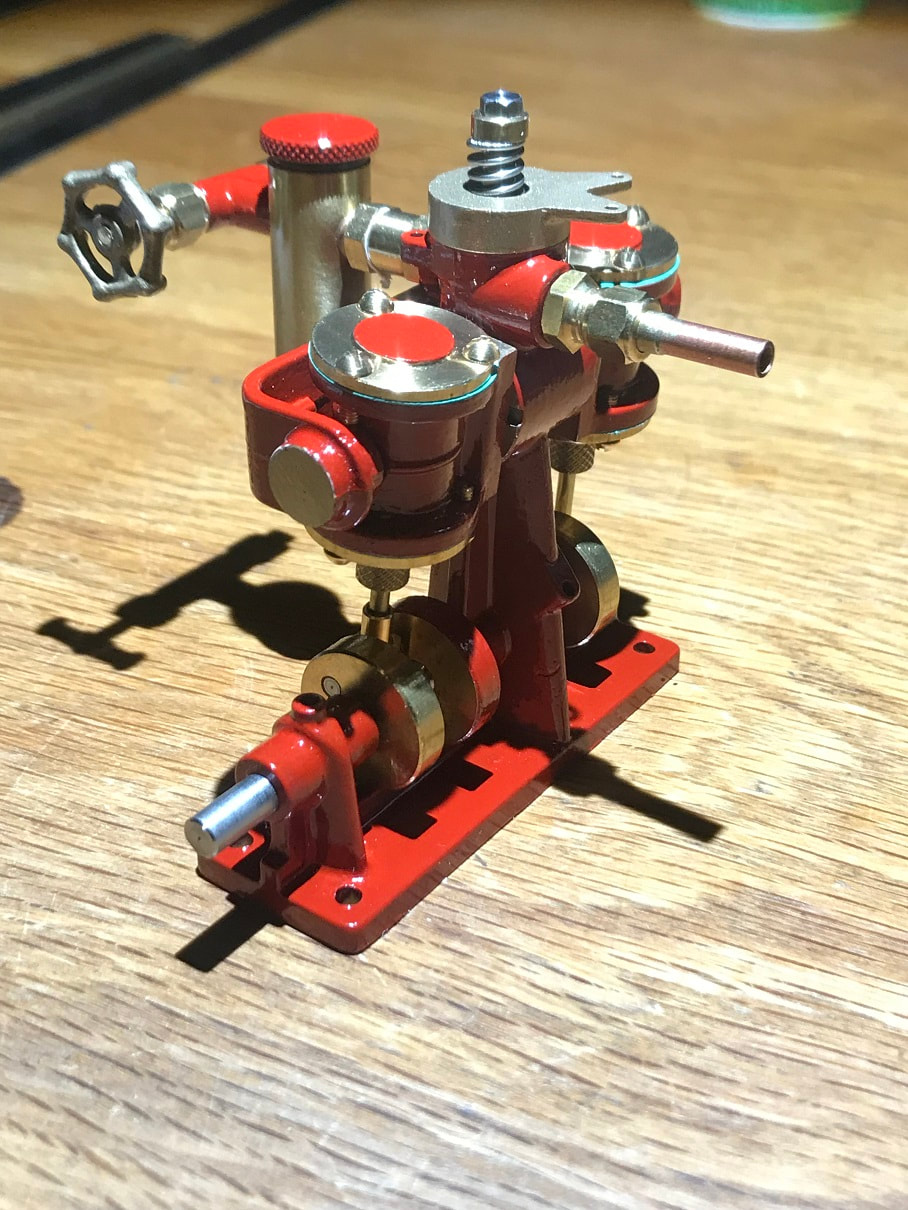

That's all for now folks, here is a photo of the completed MSM Clyde Steam Engine:

Next I ordered the fuel-tank, boiler, condenser, burner, and base-plate from MSM.