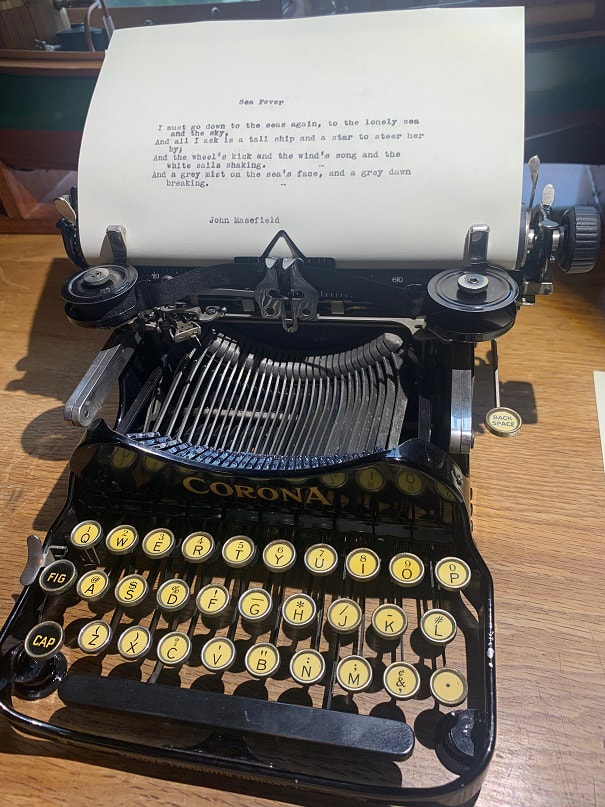

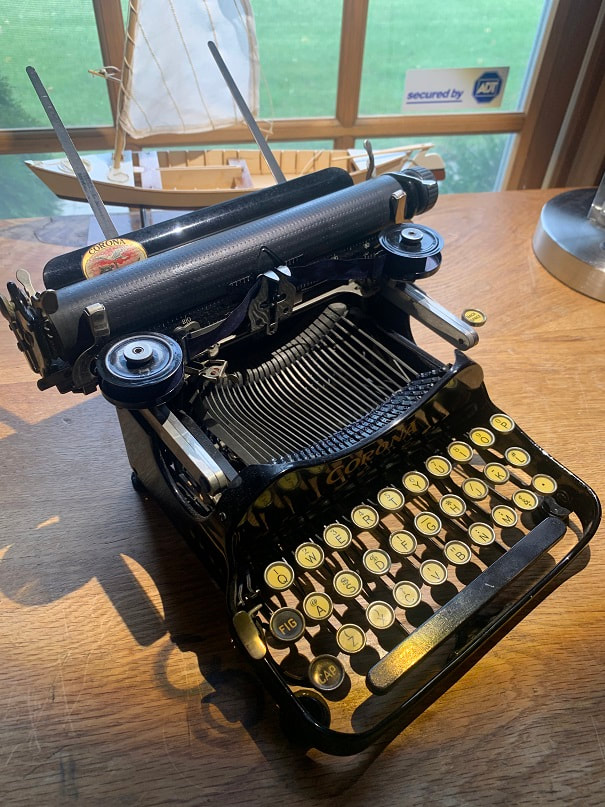

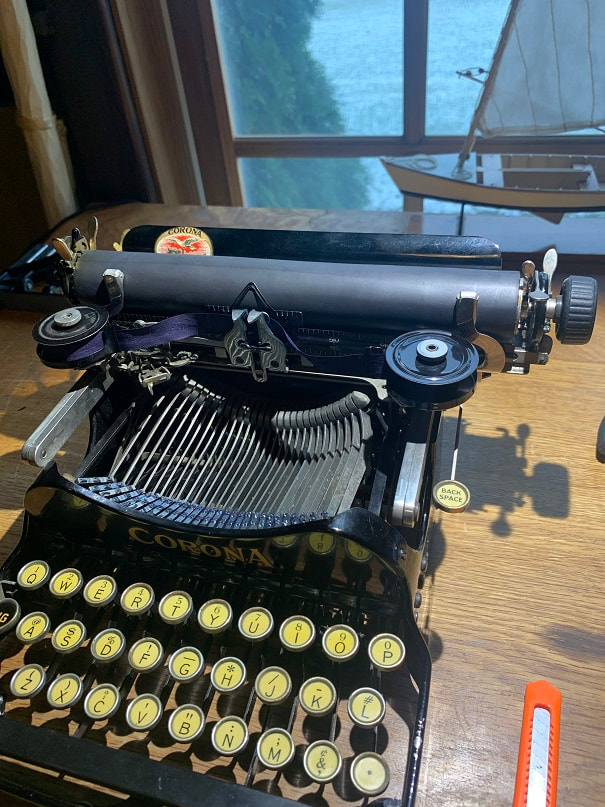

A classic typewriter with a brilliant design: the Corona 3 Folding Typewriter. This portable mechanical typewriter was one of the most popular ever made; used by the Allies in WWI and by some of the early 20th century's most famous authors. Mine is sn 458654 and was made in Groton, NY in 1917. Here is a photo gallery of the repair work I did.

Items needing repair:

- Brittle cracked rubber feet

- Platen does not feed/advance paper

- Carriage does not return

- Ink ribbon does not advance when typing

- Front case panel fabric hinge torn

Replacing the feet:

Paper will need feed or advance: Hard platen and hard/flattened feed rollers cause this.

Carefully re-install the gear and hub ends being careful to perfectly align the little metal pins embedded in the wooden ends.

Clean the paper feed tray interior well (air blast and dry brushes), then set the feed roller back in. Then set the platen back in and reinstall the shaft, reinstall the knob. It can be tricky to position the shaft back through the levers and platen, just have patience and it'll work.

Carriage does not return

The spring tensioned carriage return strap is a sinewy cord on the Corona 3. The spring on mine seemed to be well tensioned when I pulled on the return cord, but the return cord hook was not attached to the carriage, so all I needed to do was reattach the cord to the carriage.

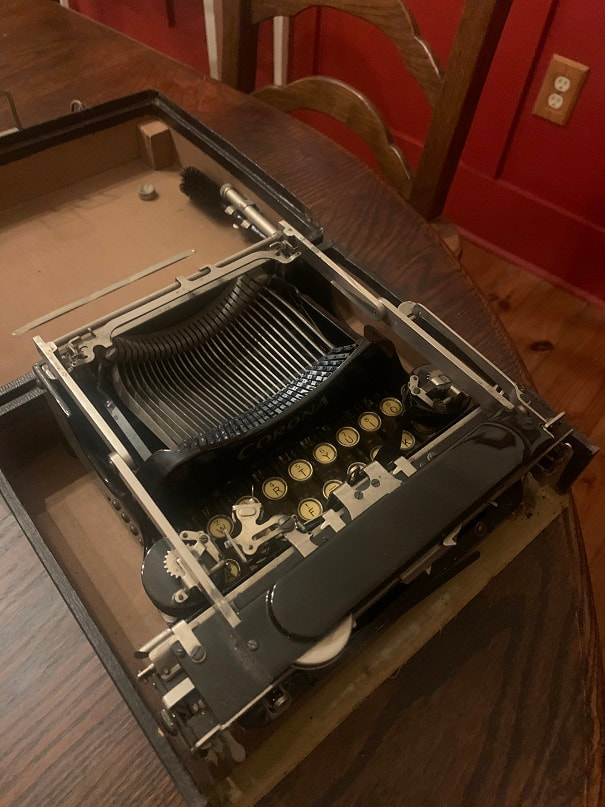

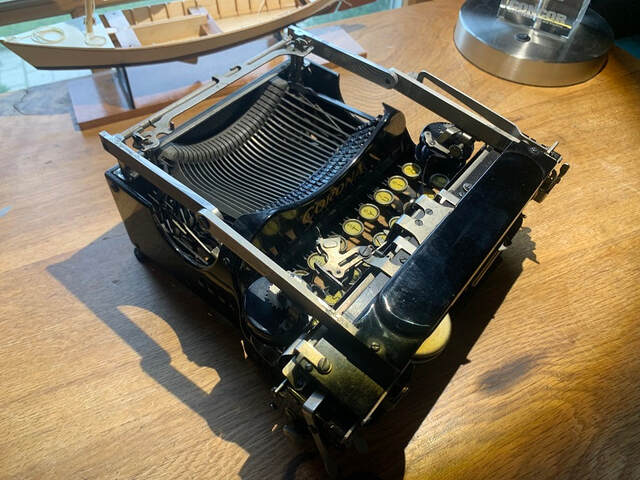

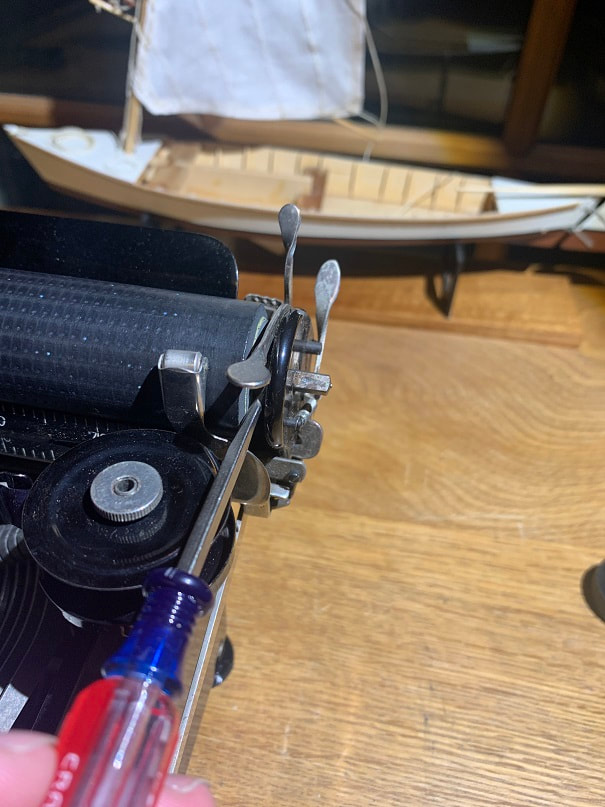

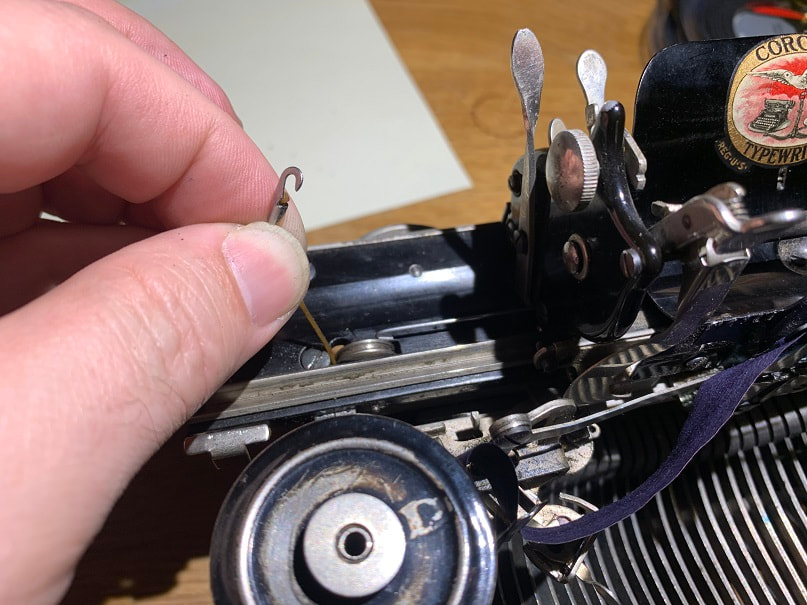

While keeping tension on the cord, I folded the folding section of the typewriter over so that I could see the top. I had made a long rigid wire hook using a length of piano wire. I carefully pushed this long wire with a hooked end from the opposite end of the carriage, under the carriage as shown, all the way until the hook reached the pulley. If you look close, you can see a silver colored wire with a hook at the end, right near the pulley.

With this, the carriage returned great, and the bell worked perfectly with no repair work needed on the bell mechanism.

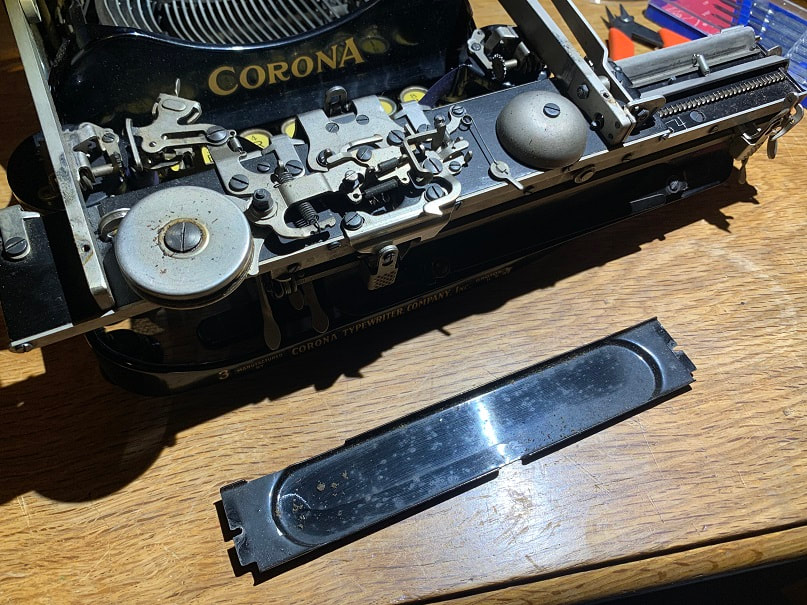

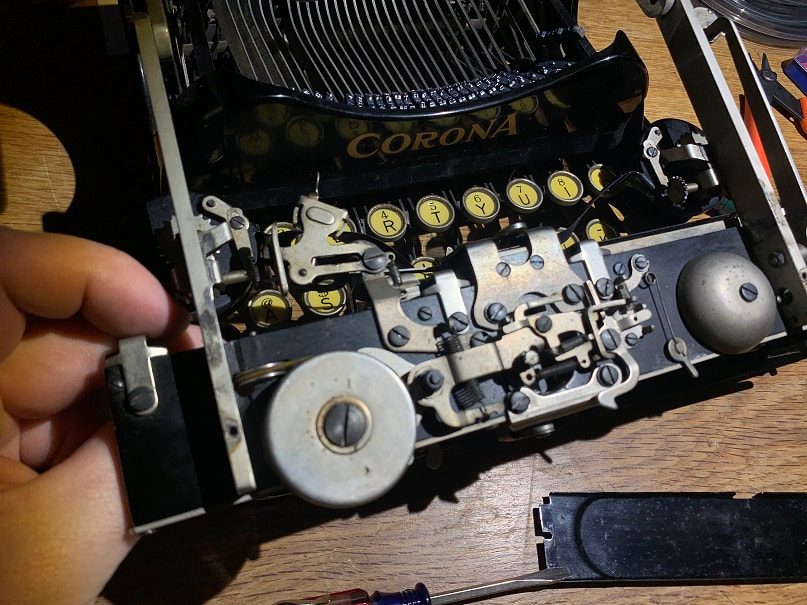

Corona 3 Typewriter Ribbon will not advance:

There is a pawl-gear, worm gear, and plain gear under each ribbon spool. When typing there is a pawl that drives these pawl gears and a tiny spring steel tang that engages the pawl gear tooth each time a letter is typed to ensure the mechanism only drives in one direction. When typing, I could see that these pawl-gears were not advancing but just rocking back and forth while staying in the same position....not rotating forward.

With those adjustments made, the ribbon advanced properly.

Replacing Corona 3 Typewriter Ribbon

The ribbon in typewriter was bone dry so I removed it. The spools were gunky and dirty so they need to be cleaned. There is a snap-spring that snaps over the ribbon holding it to the spool.

Brand new black ink ribbon installed. The little clips worked great on the Corona 3 ribbon spools. I wound the ribbon from the plastic spool it came on, onto the typewriter spool on the left, until it was full, then with the ribbon exiting from the front of the spool, I ran it through the ribbon holders up near the platen, then over through the ribbon slot on the right, and into the back of the spool on the left. This is the end of the work I will do on this machine, and I am pleased with the result!

I brushed and cleaned the case and then applied two plies of heavy duty fabric adhesive tape over the hinge joint. It is well held together and the hinge works again. That said, I would generally recommend picking up old typewriter cases by the bottom of the case, not by the handle....unless you are very sure of the case and handles soundness.