Sept 2022

Building a Model of the Oseberg Viking Ship!!

Hello Fellow Model Ship Builders!

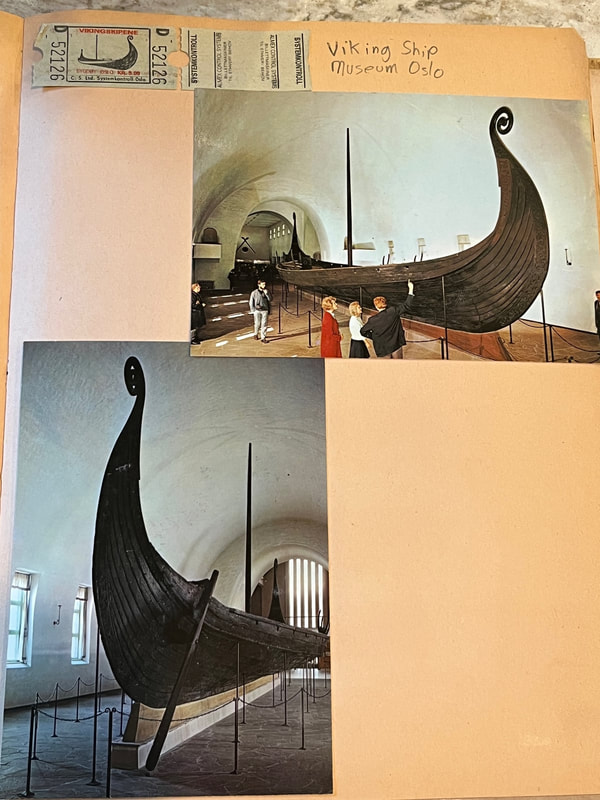

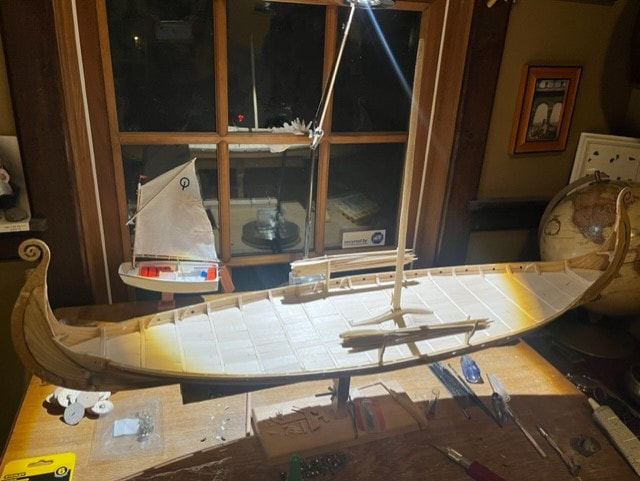

I am excited to be embarking on the construction of a model of the Oseberg Viking Ship! This ship was a ceremonial burial ship built around 800-834 AD and was excavated in Oseberg , Norway in 1904-1905. My great grand parents came from Sweden and my wife has significant Norwegian heritage, so with our bit of connection to Scandinavia, I thought this would be a fun model to build.....I also love the lines on these fast-looking Viking boats. I saw the actual Oseberg as a young teenager in the '80s in the museum in Norway, post cards (and entry ticket) from my scrapbook are posted below. I'm going to take my time, and as always I am not the fastest builder due to work and family commitments, but here goes!

Wikipedia page on the Oseberg: https://en.wikipedia.org/wiki/Oseberg_Ship

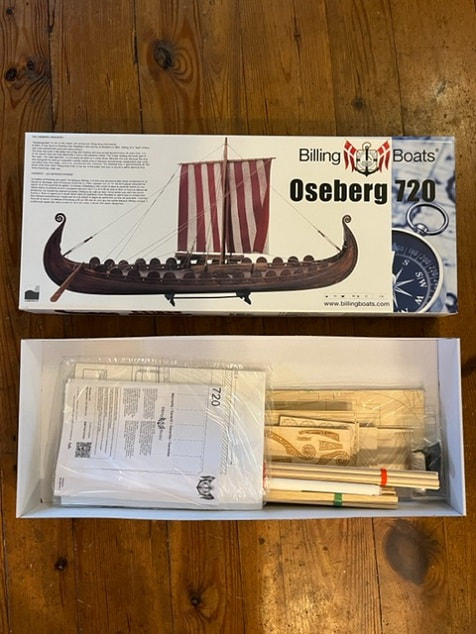

I will use the kit Oseberg 720 from Billing Boats in Denmark as the base kit for my model, though I will make many custom modifications.

I am excited to be embarking on the construction of a model of the Oseberg Viking Ship! This ship was a ceremonial burial ship built around 800-834 AD and was excavated in Oseberg , Norway in 1904-1905. My great grand parents came from Sweden and my wife has significant Norwegian heritage, so with our bit of connection to Scandinavia, I thought this would be a fun model to build.....I also love the lines on these fast-looking Viking boats. I saw the actual Oseberg as a young teenager in the '80s in the museum in Norway, post cards (and entry ticket) from my scrapbook are posted below. I'm going to take my time, and as always I am not the fastest builder due to work and family commitments, but here goes!

Wikipedia page on the Oseberg: https://en.wikipedia.org/wiki/Oseberg_Ship

I will use the kit Oseberg 720 from Billing Boats in Denmark as the base kit for my model, though I will make many custom modifications.

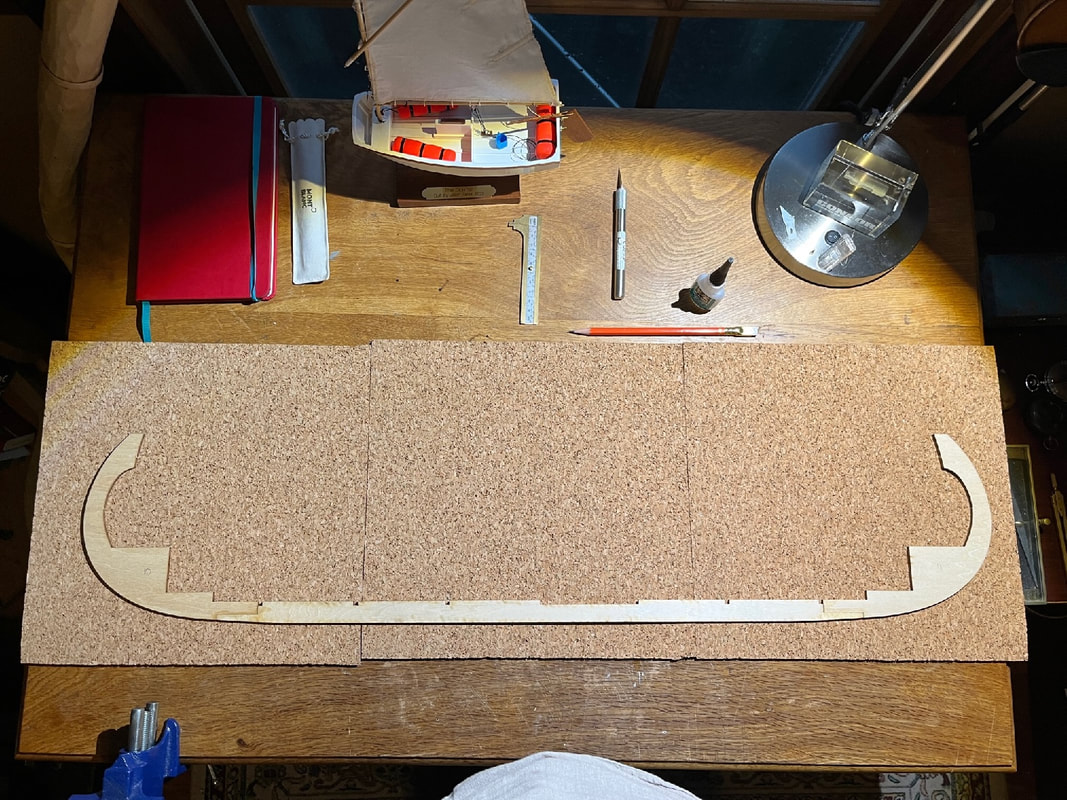

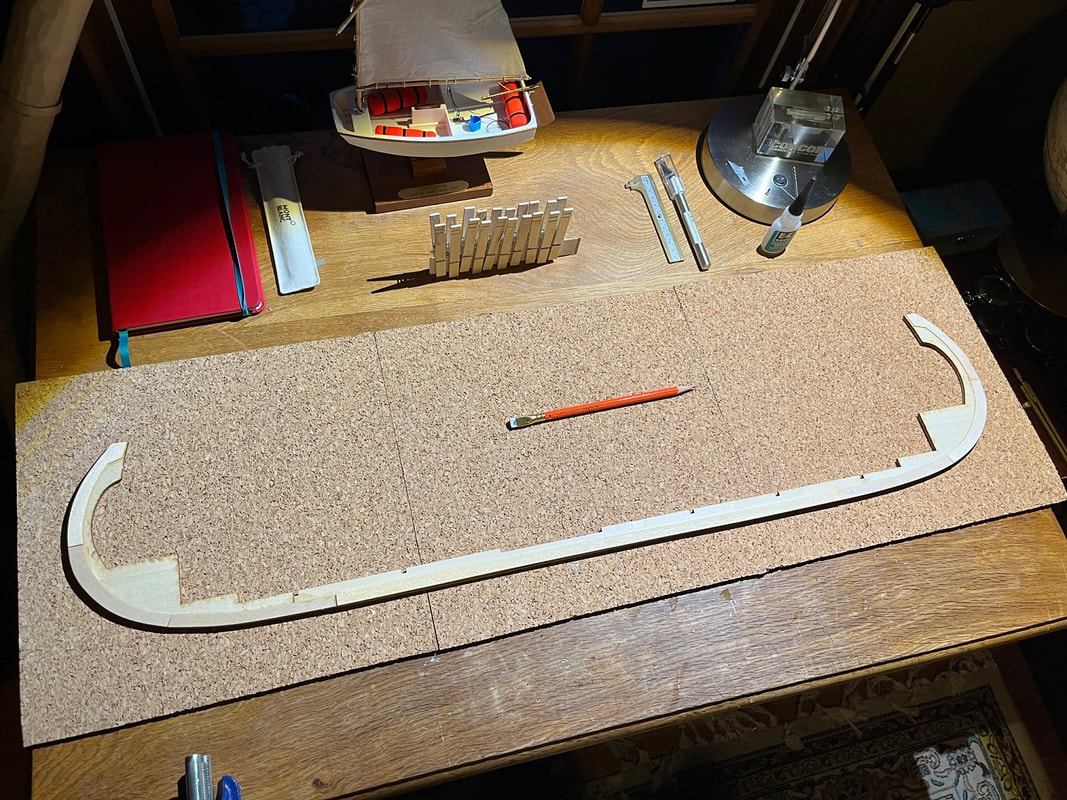

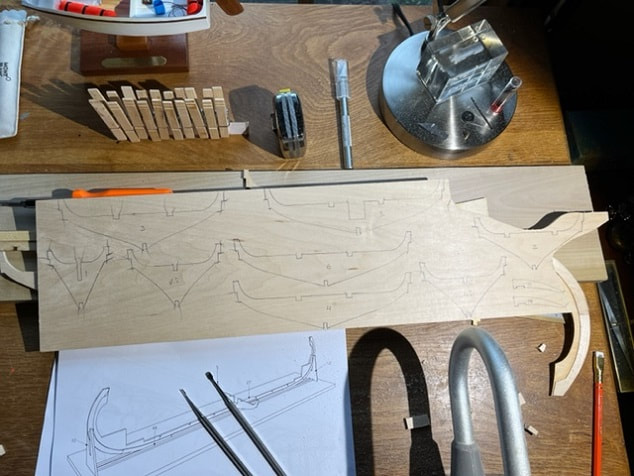

Tonight , I got started building the Oseberg Viking Ship Model. I lightly wrote the part# on many of the pieces first using a pencil. Then, I laid out the keel and glued up what I would call the keel-doublers, which are the reinforcing and thickness-adding pieces added to the both sides of the keel to build it up. I am using CA for gluing wood together.

God kveld alle sammen,

Permit me a small soap-box train of thought. I seek to minimize exposed plywood edges in my model, I also recognize my model will not be a perfect replica of the Oseberg, but I do seek to have reasonably accurately spaced bulkheads. The model from Billing Boats (Denmark) includes various plywood and plastic parts. I believe this is totally acceptable and I think that a modeler could build the stock boat from the kit and wind up with an absolutely beautiful and admirable model. Hats off to any one who builds any boat model , and to anyone who builds the stock Billing Boats Oseberg 720! Kit builders need to balance cost and time-to-build, and expectations of builders, and this would be a tough balance to strike. I am very thankful for the work done by the Billing folks; what a great model. The I will use the pre-cut planks which will be fantastic, and the nice decorative burned scrollwork in the kit, and of course the plans are so nice and essential and hard earned by the designers. Buying the kit provides me with perfect laser cut wooden templates with which to make solid wood parts. Thanks Billing Boats designers!! This said, I will be recreating many plywood and plastic parts with solid wood, and I will be adding the visible parts of bulkheads that are missing from the kit plans. I utilized the plywood keel for stability and I will use the plywood parts in below-decks spots. Visible parts will mostly, but not always, be recreated with solid wood parts, as will be seen in the build log as I progress. I am not a perfectionist so for example I may use the plywood shields from the kit, because I think they look cool, and also I do not yet know if I will place metal nails along all the hull planks as Von Kassa and Jack P did (their end results were truly amazing!). OK, enough writing, I will get to the fun part....pictures.

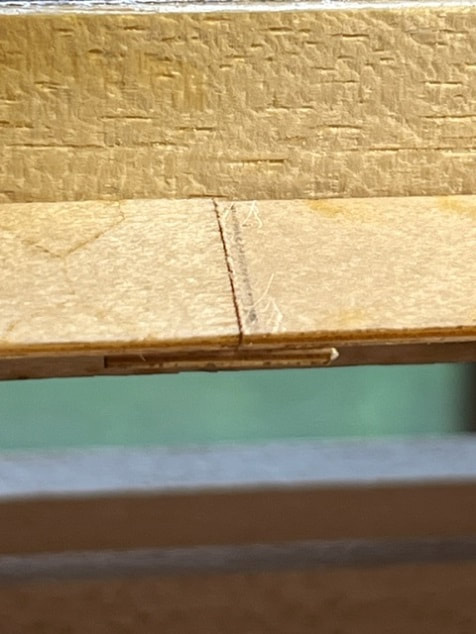

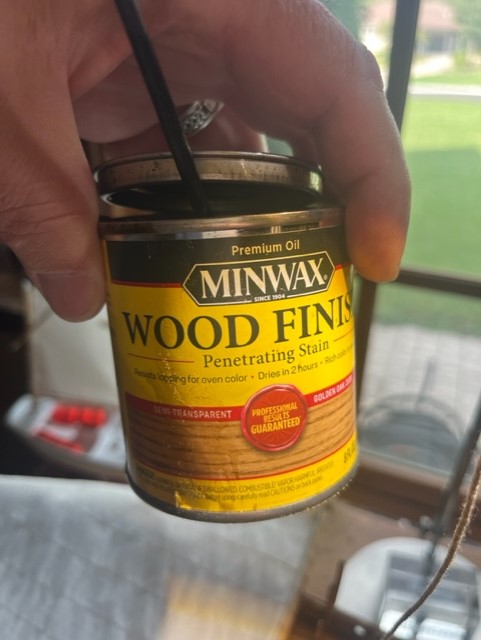

I contemplated using the plywood bulkheads. They are made from very high quality plywood and are well-cut. I will not be staining my ship as dark as the ship looks in the museum in Norway, I will be shooting for a carmel colored lighter finish. I tested a stain similar to what I will use on the end-grain of the plywood bulkhead to see how visible the plys would be, and unfortunately I thought the plys were to visible so I need another solution:

Permit me a small soap-box train of thought. I seek to minimize exposed plywood edges in my model, I also recognize my model will not be a perfect replica of the Oseberg, but I do seek to have reasonably accurately spaced bulkheads. The model from Billing Boats (Denmark) includes various plywood and plastic parts. I believe this is totally acceptable and I think that a modeler could build the stock boat from the kit and wind up with an absolutely beautiful and admirable model. Hats off to any one who builds any boat model , and to anyone who builds the stock Billing Boats Oseberg 720! Kit builders need to balance cost and time-to-build, and expectations of builders, and this would be a tough balance to strike. I am very thankful for the work done by the Billing folks; what a great model. The I will use the pre-cut planks which will be fantastic, and the nice decorative burned scrollwork in the kit, and of course the plans are so nice and essential and hard earned by the designers. Buying the kit provides me with perfect laser cut wooden templates with which to make solid wood parts. Thanks Billing Boats designers!! This said, I will be recreating many plywood and plastic parts with solid wood, and I will be adding the visible parts of bulkheads that are missing from the kit plans. I utilized the plywood keel for stability and I will use the plywood parts in below-decks spots. Visible parts will mostly, but not always, be recreated with solid wood parts, as will be seen in the build log as I progress. I am not a perfectionist so for example I may use the plywood shields from the kit, because I think they look cool, and also I do not yet know if I will place metal nails along all the hull planks as Von Kassa and Jack P did (their end results were truly amazing!). OK, enough writing, I will get to the fun part....pictures.

I contemplated using the plywood bulkheads. They are made from very high quality plywood and are well-cut. I will not be staining my ship as dark as the ship looks in the museum in Norway, I will be shooting for a carmel colored lighter finish. I tested a stain similar to what I will use on the end-grain of the plywood bulkhead to see how visible the plys would be, and unfortunately I thought the plys were to visible so I need another solution:

Completing Bulkheads on the Oseberg Viking Ship Model:

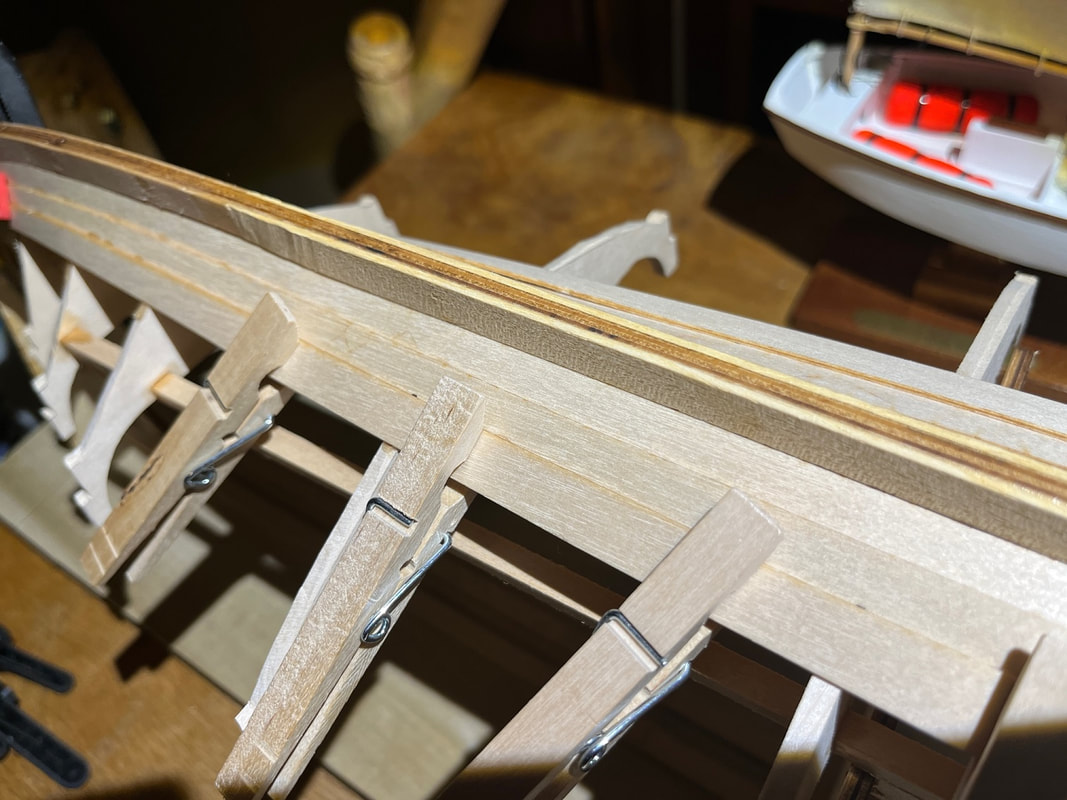

Planking the Viking Ship Model Oseberg:

BEFORE PLANKING, I will now use razor knife to chamfer the bulkheads to match the curve that the planks will follow across the bulkheads.

Planking the Oseberg Viking Ship Model:

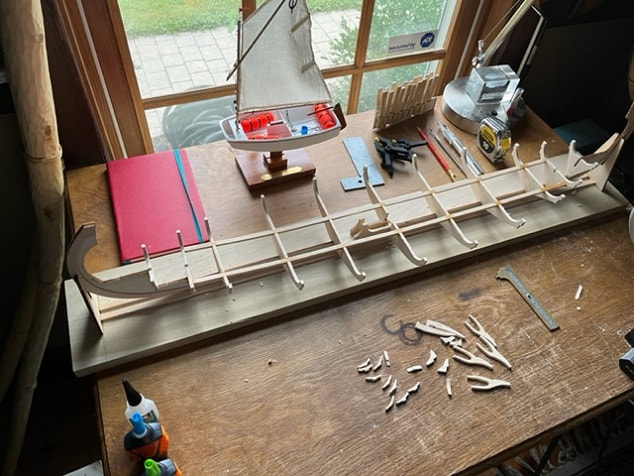

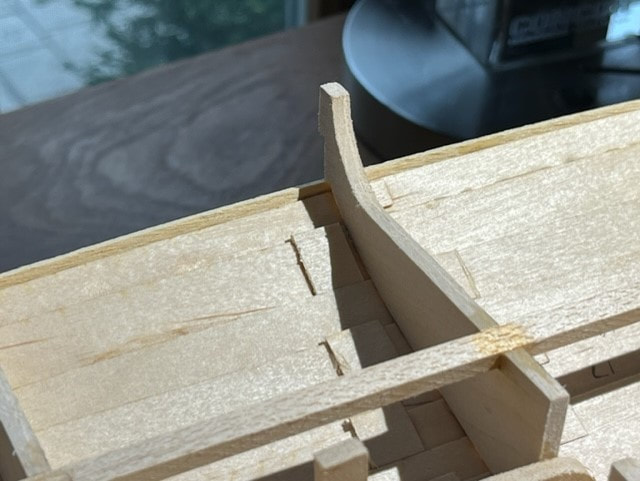

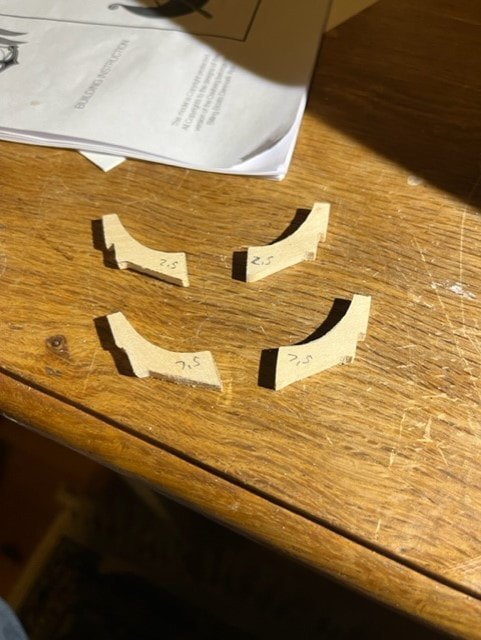

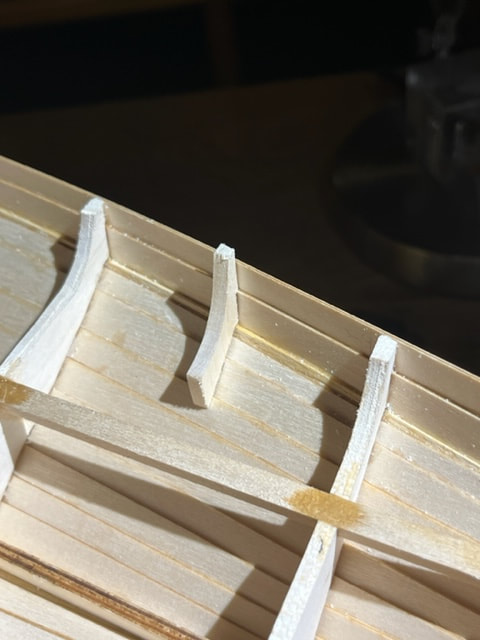

Making and installing the bulkheads that are missing from the kit:

If you look at the plans, or at the photo just above, you will see the first three fore and aft bulk heads spaced closer together, and then you will see large spaces between all the middle bulkheads. In the actual ship, the space between bulkheads was not as large as those big spaces in the kit. I will build small stub bulkhead tops, and glue them in place in the center of the large spaces between bulkheads in the kit, so that the bulkhead spacing in my model looks more accurate.

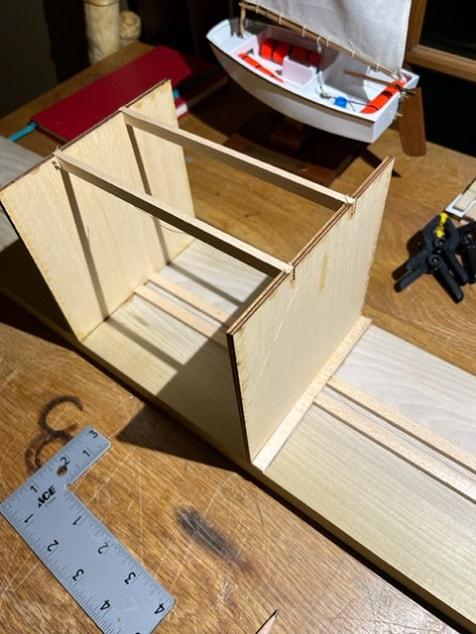

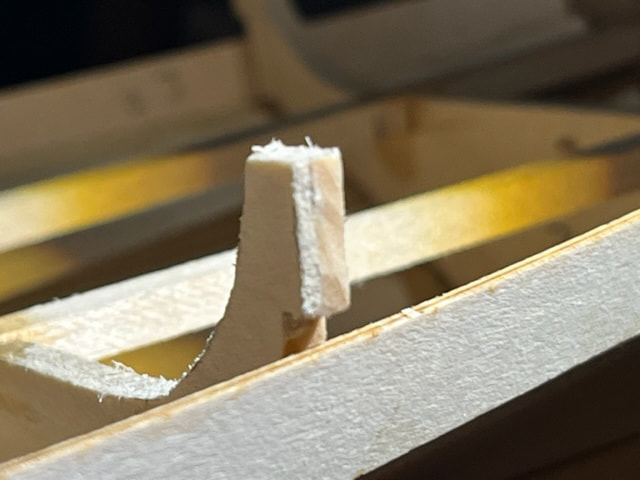

Making the Oseborg Viking Ship Mast Partners:

I used the plywood assembly from the kit as a template to build a solid version from Basswood. Here are the steps I took.

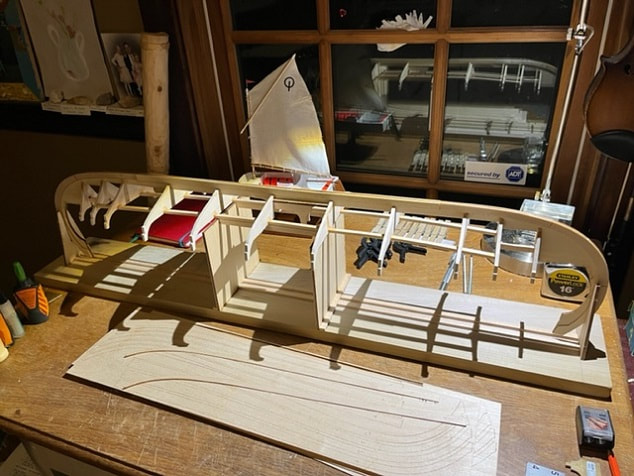

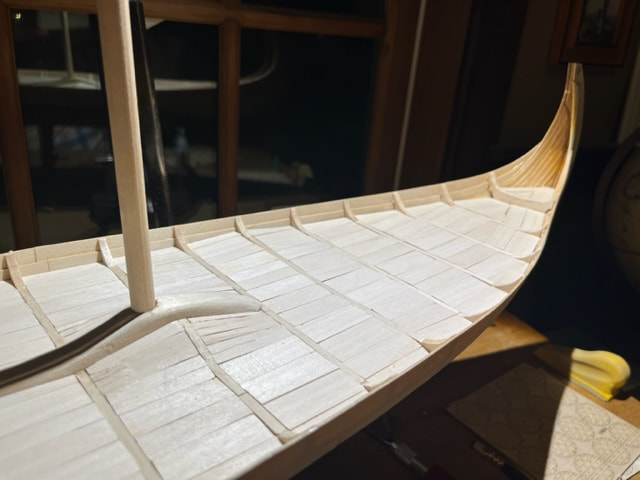

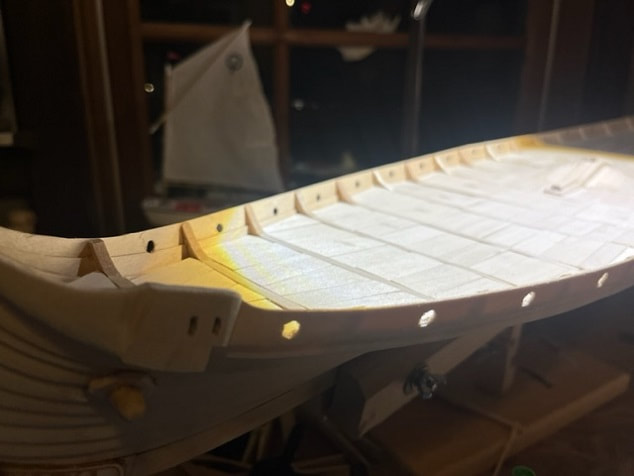

Planking the deck on the Oseberg model, and finishing the tops of the bulkheads:

I have completed installation of the plank support strips on either side of all the bulkheads. I have more bulkheads that the standard kit, so I ran out of the little strip material and used small basswood strips after the kit material ran out. Next, I will build up the tops of the bulkheads with wooden strips so that the tops of the bulkheads are flush with the tops of the planks; see photos below. This is a deviation from the kit, but is more accurate vs the original. The Oseberg ship has small planks that run from bulkhead to bulkhead and which are staggered in lengthwise alignment with the planks between the next bulkhead....ie the mini planks are not all in one big aligned row down the deck of the ship.

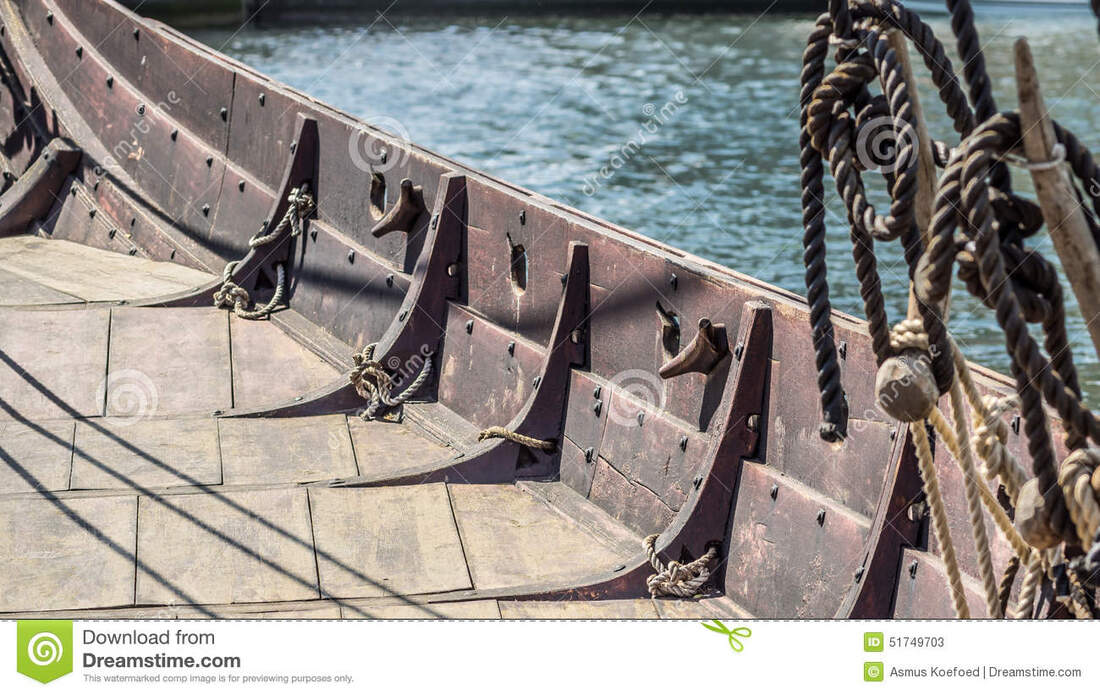

The deck of the actual Oseberg can be seen below. Also, I note the shape of the bulkheads above the deck, I will carve mine to be more similar to this:

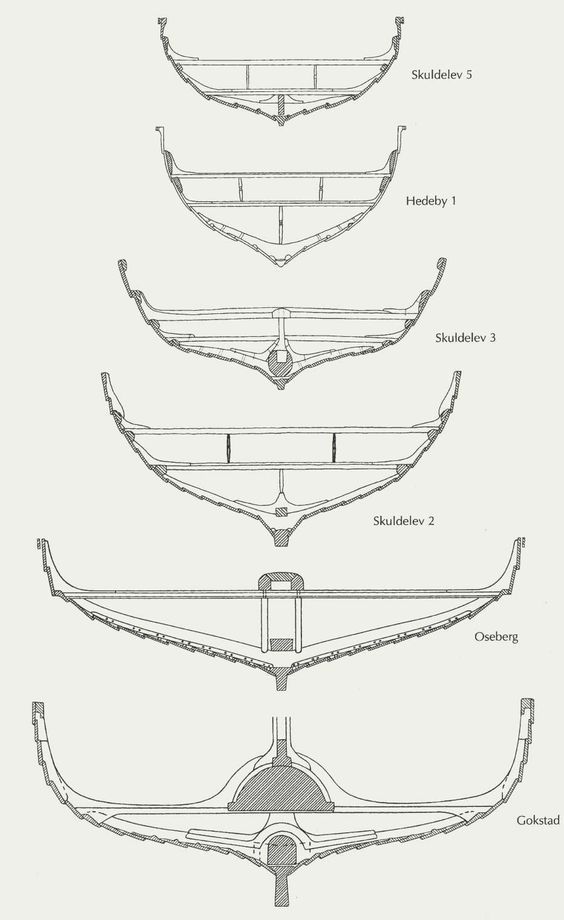

Also, sidenote, from looking at sketches and photo's it seems the Oseberg was not built with solid bulkheads but with thwarts that would run from starboard to port that supported the deck. I think this would have been lighter and allowed for more storage space and storage of longer objects. Various viking ship cross sections can be seen below. I still need to build the arched "bulkhead/thwart" that partners.

I bought a bunch of 1/16" solid basswood sheets to finish the bulkheads with, and to make the planks from. I am now adding a 1/6" strip to the tops of the bulkheads. As I go I am also carving down the bulkheads so that they taper to a point at their tops. The photo below shows the strips that will be the exposed tops of the bulkheads, and also what the carved tops of the bulkheads look like vs the uncarved ones.

Planking the Oseberg Viking Ship Model:

Looking at the photo's of the Osebergs deck, I believe they feature random width planks. One can also see the orientation of the planks. I am planking my planks cut by hand to random widths, with a razor, from 1/16" thick sheets of Basswood.

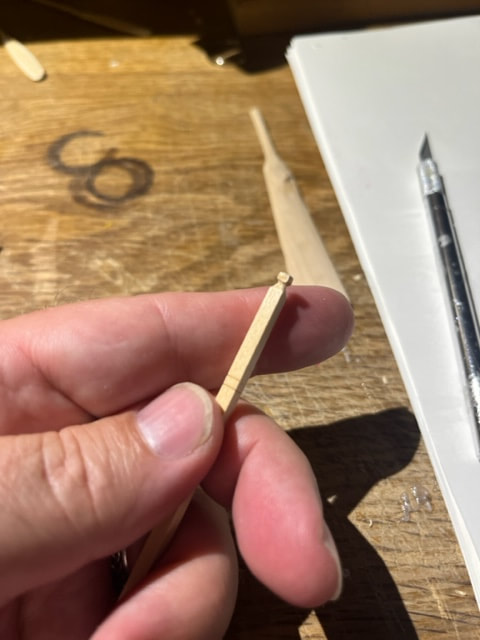

Making the oars:

Repetitive task here to make 30 oars. From the photos I could find, the handle-end of the viking oars were just simple tapered ends, so that's how I made mine. I used the components from the kits, tapered the oar blades with a knife, and then sanded them.

Making the Oseberg Mast and Spars

Oseberg Viking Ship Model Rudder and Tiller Assembly

Below are some photos of the Oseberg ship rudder and tiller and how they were attached to each other and the ship. For these components, I carved my model pieces from solid basswood rather than using plywood cutouts from the kit.

Finishing the Hull:

A prominent feature of the Oseberg ship, maybe THE MOST prominent feature, are the tall carved stems at the bow and stern. If one looks at the actual ship, these are quite thinner and more tapered fore and aft than what the billings kit suggest in their design. Building to the design of the kit will build a nice model, but the bow and stern will be very thick and blocky vs the Oseberg itself. I like many others before me, took the time to carve away the frameworks under the bow and stern carved pieces to result in a finer stem and stern.

Making the shields and shield rail on my Oseberg Viking Ship model:

Tonight some work in the armory....shield building. First a note on a interference problem. I used what I thought was the right wood stock from the kit to make the little blocks above that create the spacing for the shield rail. Then I tapered down the ends of the shield rail and glued it in place. I then went to go install my happy little shields only to find that the shields were to thick to fit into the space. Uf-da. I wasn't about to rip off the rail so I sanded the shields down slightly and they not fit. Downside was that in the process of sanding, the little nail hole etches laser-scribed into the shield faces became actual holes. I will fill these with a nice darker color wood filler and will wind up OK. Just be careful to check the thickness of the blocking material vs the shield thickness. 3/8" diameter furniture upholstery tack used for center of shield; I picked a bronze type color, but I think the vikings used iron for these parts; I wanted the bronze color to look better with the stain I will apply so permit me this inaccuracy of metals......the bronze age ended at least 1000years BC and this ship is from 800AD. But then again the Vikings painted their shields so I am going with that the Vikings on this ship painted the shield centers this color. Now I have some cleanup and sanding to do on the shield rail and the shields.

Cleats , Spars and Final Trim Pieces

Final Trim Pieces At the Prow and Stern

Note which edges of these trim pieces are flush with adjacent woodwork and which sections sit stop adjacent pieces.

Sewing the sails for the Oseberg ship model:

Installing the rudder and staining the ship before rigging:

Rigging the Oseberg Viking Ship Model:

I used some smaller scale rope I had in stock for some lines, but mostly used the cotton rope supplied in the kit. I started rigging the ship using the very white rope in the kit but it was too bright white in my opinion so I took the whole spool of rope and dunked it in the can of stain and the pulled the rope out of the bucket through a rag to press the stain out and this resulted in a nice color rope for the ship.

Making the base for the Oseberg Ship Model

I will make the stand for this ship out of Aspen which is a bright white clear grained Nordic softwood. I will add some celtic carvings for fun.