With the hull painted and flipped back upright, I will now begin the rewarding and exciting process of mounting the hardware to the SCAMP's hull and deck.

Oarlocks

First, I installed the oarlocks. This photo shows the square-edged section of cockpit-coaming-cap where the oarlock is mounted. The coaming reinforcement gussets can also be seen, for more detail on those, you may visit the Deck and Coamings page. The oarlocks are bedded with 3M 4200, and secured with #10 bronze screws.

Bow Eye

Organizing and Preparing for Hardware installation

Installing Deadlights

Roof Top Hardware

Tufnol Camcleat (to secure the boom-downhaul) is through-bolted with backer plate on the roof interior, on the port-side of the roof. The chafe-protection strips, made of clear fir, can also be seen bedded onto the fore and aft edges of the rooftop. Bedded in 3M 4200, secured with silicon bronze fasteners.

The lower boom-downhaul block is a Tufnol double block with becket, mounted to the roof top with a through-bolted bronze pad eye. To starboard is a Tufnol single block mounted through a small bronze padeye; this block is for the halyard. They are bedded in 3M 4200 and mounted with silicon bronze bolts through the roof and through the roof beams.

Cockpit and Veranda Interior Hardware

Two Wichard flip-up pad-eyes mounted at a strong spot in the veranda. I have two of these in a similar location in my Compac 16 and I use them for life-line/tether lines, or other tie-down uses. They are very strong and have 3/4" thick white oak backer plates on the other side. Bedded in 3M 4200 and through bolted with stainless steel fasteners.

SCAMP Centerboard Uphaul Tackle and Rigging

I went with a 3/8" diameter brass tube, I may regret brass vs copper, and I may regret using 3/8" instead of 1/4" diameter. Perhaps the 3/8" diameter that I chose, will leak water into the cockpit? I will let you know after I go sailing. I choose 3/8" diameter so that I would have a free-flowing line, and if I want to upsize the line to 3/8"later, my tube will accommodate. I flared it by pounding this flare shanked screw-driver into it.

For the centerboard uphaul tackle, I have mounted a Tufnol cam-cleat-with-bullseye and Tufnol single block-with-becket. Both are offset with 1/2" (12.5mm) hardwood blocks to keep the lines and fiddle from hitting the side, both bedded in 3M 4200 and secured with long screws into the aft centerboard case column.

Transom Hardware

The SCAMP Argo will have the following pieces mounted to the transom. All of these will be mounted into holes that have been drilled oversize, then filled with epoxy, then re-drilled with the final mounting hole.

- Two drainplugs

- Boarding ladder

- Rudder gudgeons

- Motor mount

SCAMP Argo's Motor Mount

Garelick Motor Mount Adapter Plate #71053, allows the motor mount to be easily slid on or off. It is mounted using stainless-steel fasteners and is mounted through 1"x1" white oak spacers. Bedded in 3M 4200. The spacers hold the motor mount enough astern to allow the lever arm of the motor mount to function properly. I doubled the thickness of the transom in this location, per plans, to provide a strong anchoring location for the motor.

SCAMP Sailboat Pintles and Gudgeons

The pintles and gudgeons are cast bronze, from Davey and Co. The jaws of the pintles were slightly narrower than the thickness of my rudder stock, so I needed to cut in recesses in the stock in order to mount them. Details here. I then bedded them in 3M 4200 and secured with silicon bronze screws.

Mainsheet Traveler Hardware

The Argo will feature an adjustable mainsheet traveler. The port and starboard ends of the transom-cap will have holes fitted with bronze shoulder bushings, and beneath these holes, in the cockpit, will be a cam-cleat-with-bullseye, on each side.

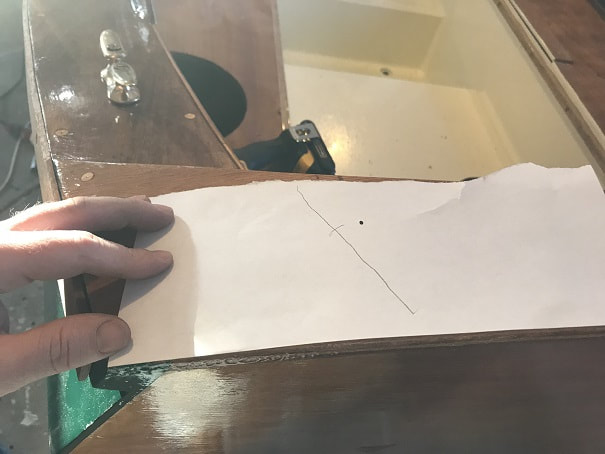

One little trick I have found helpful for symmetrically locating holes and hardware, is to mark holes through a sheet of paper that is held along an edge at a specific reference point. This sheet of paper can be flipped over and held in the same position on the other side of the boat to quickly locate a piece of hardware in the same spot on that other side.

5/8" ID, 3/4"OD, 3/4" long bronze shoulder bushing installed in the transom cap. This hole is located just inboard of the coaming. I will be mounting a cam-cleat-with-bullseye on the coaming and the traveler line will run through this bushing right into the cam cleat. The bushing is there to seal up the hole well and also to provide chafe resistance where the line runs through the transom. I scored the OD of the bushing and then epoxied it in place. I coated the wooden hole ID with unthickened epoxy first, then thickened the epoxy and installed the bushings..

Two Tufnol cam-cleats-with-bullseye, are mounted as part of the mainsheet traveler system; one on the starboard coaming and one on the port coaming. With these, I will be able to quickly and easily adjust the traveler-line length. Through bolted through backer, bedded in 3M 4200. The motor mount doubler can alse be seen on the port side of the transom in this photo.

DECK HARDWARE

A Davey&Co bronze, closed chock is mounted front and center on the ship. It is bedded in 3M 4200 and mounted to a beveled platform which orients the chock so that it is parallel with the rooftop. The anchor line will pass through this chock and then be made fast up on the roof. (note: Those bow rub rail mounting holes will be plugged)

Next the port and starboard 5" bronze Davey&Co open cleats were mounted at the bow. These are mounted through the backer plates that were built into the boat during construction. I tried to climb in through the bulkhead hatches to reach the ends of the silicon bronze machine screws, but my own body diameter was too large and did not allow for enough forward progress to allow me to reach the fasteners. Luckily, in one of the few but critical moments that my wife helped with the boat, she crawled into the bow locker and held the nuts as the cleat screws were tightened down. Thanks Sandie!!!

SCAMP Rub Rail

Cracked rub rail, removed, scraped clean, and ready for installation of new piece. During the calamity of the cracked rub-rail, the 3M-4200 got all over the top plank of the hull and required Acetone to remove it....which dulled my beautiful finish. Here I have sanded the plank down with 220 grit and will repaint it.

SCAMP Sailboat Fire Extinguisher

Oar Storage Holder for the SCAMP Argo.

The ARGO is fitted with 8foot oars that can be stowed in one piece in the cockpit. I mounted "Quick Fist" rubber holders to hold the oars tightly in place so that they don't rattle around.