January 2021

Handmade brooms are artisanal pieces of craftsmanship that look and work great! You don't need to worry about putting a beautiful handmade broom away, you will want to leave these handcrafted pieces out to show.

How to make a traditional Broom-Corn Broom:

Photos of the finished product, followed by instructions on how to make a traditional broom-corn broom.

Sweeping up one's abode or workplace has been a task that has been done for thousands of years. This is a noble and time honored chore. Broom corn is a sorghum plant (not actually corn) that originated in Africa and that was brought to America by Benjamin Franklin. The fibers are tough and as the broom is used the fibers continue to split in such a way that they trap and sweep dust excellently. This is not just an antique material for broom making; go look at Lowes or Home Depot and you will find mass-produced corn brooms are still made because of the superior performance of the broomcorn material.

First, here are the tools and materials I used for making a handcrafted corn broom. Note that there are true artists in this craft, of which I do not count myself as one, but I can tell you how to make a really nice broom; see below.

Materials:

- Broom Corn , for this broom, about 40 stalks of full-size broom corn (there is a smaller variant of broom corn that can be used for small brooms)

- Broom stick: this could be many things! Sticks with the bark still on are popular and can be found in the woods. I use rough sawn ash, that I hand-carve into broom sticks.

- Tarred 18 gauge nylon bank twine for wrapping the broomcorn onto the stick and also for plaiting the broomcorn on the handle.

- Waxed hemp for stitching the broom flat

- Leather strips to make a loop at the end of the broomstick, to hang it by.

Tools for Broom Making

Foot winder; you can use a simple stick and wrap twine around that. Foot winders such as the one pictured here are common also, and work great. I made this from scrap pine, it is 2 feet long and it is glued and screwed together. You wrap your twine around this, and than hold this winder in place with your feet and pull on the broom as you rotate it. This allows you to put good tension on the twine and get a nice tight wrap. You rotate the winder with your feet every once and a while to release more twine.

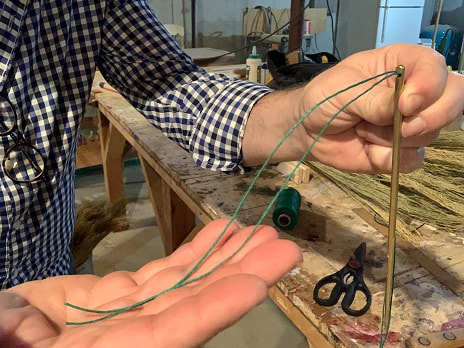

Big needle (or if you want to sound cool, call it a bodkin), for stitching the flat part of the broom. I made this one. It is 8" long and made from 3/16" diameter brass rod. I pounded the end with the eye flat, then drilled out the eye, then ground and sanded down the pointy end. The end shouldn't be razor sharp. I think this is one of the cooler tools you get to use when making a broom by hand.

- Sharp, stout, large scissors, or sharp shears, for trimming the end of the broom

- Large bucket for soaking the stalk-ends in water

- Depending on what kind of broomstick you want, you may need some tools. Some people use sticks they find in the woods, or you could buy a broom stick, or you could carve/shape one from lumber. If you make one from a piece of lumber, you will need saws and tools such as planes to do that.

Now, Here's how to make a Broom-Corn Broom by Hand!

First, find or make a broomstick:

One can choose many different types of materials to make a broom stick. It is popular to forage a stick with the bark on and use that, if you do that be sure to let it dry out for about 6 months. At the end of the day, you want a strong stick that is 3/4" to 1" in diameter and 36" to 56" long depending on your preference. The broomstick I made here is 46" long and 1" in diameter. I made it from Ash, which is a classic strong wood for broomsticks.

Four different Ash broom sticks; spiral carved, round with a knob-top, round, and octagonal. I sand the corners of the octagonal sticks so that they are smooth and comfortable to hold. If I want to color the tops, I dip them in rustoleum enamel and hang them to dry, the paint should be put on before oiling the rest of the broomstick.

Natural Tree Branch Broomstick

With the broomstick ready, it's time to tie on the broomcorn!

I'd recommend setting up a nice uncluttered space and have all your materials and tools within arms-reach of where you sit to tie your broom. This will be a kitchen broom with

- A 1" diameter x 46" long Ash handle

- An inner broom corn layer consisting of 12 heads of broom, whose stalk-ends have been sliced in half (details below)

- "Shoulders" that make the broom a bit wider. These are tied on opposing sides of the broom to add width, so add them to the sides of the broom that you want to be the sides not the front and back. Each shoulder consists of 3 cornbroom heads, so 6 in total needed. The stalk-ends of these pieces are also sliced in half and trimmed.

- A final outer layer of broomcorn , about 16 heads, whose stalk ends are not sliced in half.

First, fill a tall bucket with 12" of hot water from the tap. Place the broom corn stalks into the water to soak. Put the stalk-end in the water and leave the frayed bristle ends sticking up out of the water. Keep the broomcorn within arms reach so you can grab it. For this broom, which was made on a 1" diameter stick, I started with 40 heads of broomcorn. You'll want them to soak for 20 minutes or so before you start so set them in the water first and then get everything else ready.

Find out how many heads of broomcorn will be needed for the first layer by placing broomcorn around the circumference of the broomstick and holding it on with your hand. It takes some jostling around but make sure sure each piece of broomcorn is tight up next to the adjacent pieces. Count how many it takes. In my case it was 12 pieces.

Once the broomcorn stalk-ends have been sliced in half, trim them to length. The stalks ends for the inner layer and the shoulders should be cut to a length that is 3" past the "knuckle" where the fibrous brushes start. A couple pictures down from here you can see a picture of these trimmed stalks.

Place the broom corn on the stick. Pull tension on the twine and slowly wrap the twine over the broomcorn stalks about 1/2" up from where the bristles start. Here's what the first layer looks like with half of the cornbroom heads placed around the broomstick. Note the 3" long stalk ends, and also note that the flat face of the stalk is placed against the stick with the round half facing out.

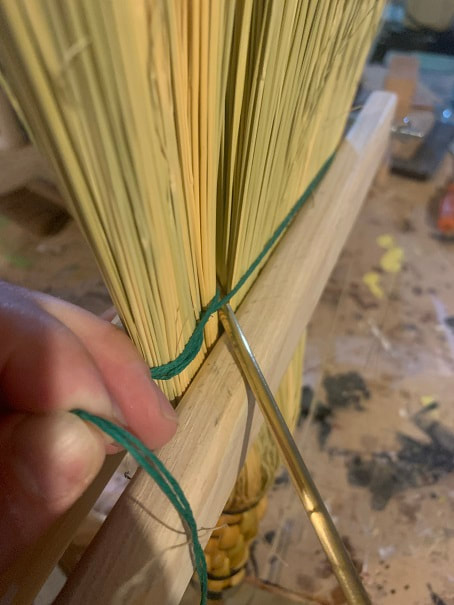

Always keeping tension on the twine, next, "plait" the remaining ends of the broomcorn. You are essentially using the twine to weave the stalks tight to the broompole. Take your twine and loop it over and under, over and under, over and under the stalks, pulling the twine tight as you go. Spiral the twine up in rows as you go and a pattern will emerge that looks like the photo. You want an odd number of stalks so that you get an alternating plaiting pattern. If you have an even number of stalks, just split one with a knife down the middle. Keep plaiting up the stalks, I made rows about with about 1/2" spacing. NOW FOR THE FINALE. Make two tight wraps around the broom corn when you get up to about 1.5" from the end of the shortest stalk. Then take the 12" ripcord loop that you made at the start and lay it over the most recent wraps of twine. As you work, always keep tension on the twine.

The wet ends of the stalks can warp as they dry, so to keep them holding a nice shape, wrap some temporary twine around the tips while they dry.

Take some twine and lightly wrap around the tips of the trimmed ends of the broom-corn. Tie of the twine to the broomstick. After the stalks have completely dried out in a couple days, you can take this twine off.

On the left is a broom built exactly as described above, prior to stitching it flat. On the right is a similar broom, after being stitched flat, but before trimming the bottom of the broom corn. I made these today at the same time, and one can see that the top of the broom corn is still wet. I have been using pipe clamps to hold the tops of the broom corn tight as it dries, as can be seen in the photos.

Stitching the broom flat

At this point you have a broom that is generally round in cross section. We can all thank the Shakers for coming up with the innovation of stitching the corn broom flat to make a broom that sweeps a wider swath. Thanks Shakers!

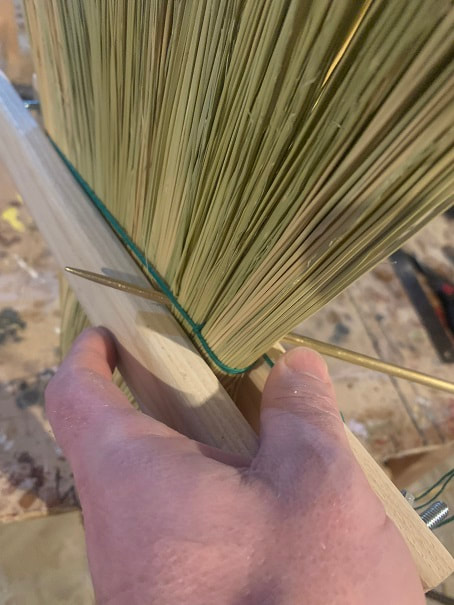

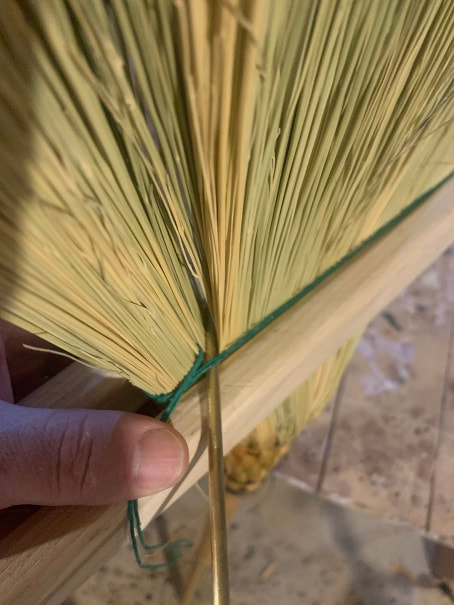

It is tough to describe how to stitch a broom using words alone. I think the pictures below might be more useful. Hopefully with the words and pictures together, this is a useful set of instructions.

It is tough to describe how to stitch a broom using words alone. I think the pictures below might be more useful. Hopefully with the words and pictures together, this is a useful set of instructions.

Cut an 11ft length of hemp twine and fold it in half. Take the two loose ends and thread them through the eye of the bodkin (big needle) as shown. I tie them off to the eye so that they don't come out. I use a bowline knot for this but you can use most any ole knot. With this done, you have a 5 1/2 foot long length of double strand twine, with a loop on the other end.

IMPORTANT NOTE: This initial loop of doubled up twine that goes around the broom, I will call the "cross-broom-twine". It is easiest to stitch a broom with the handle on the ground and the broomcorn pointing up. So with this in mind, please note when I write "BELOW" I mean on the side of the cross broom twine that is towards the handle, and when I say "ABOVE" the cross broom twine I mean on the side of the cross-broom-twine that is up towards the end of the bristles of the broom.

This first stitch is a little different than the rest, after the first stitch, the stitches will be the same till you reach the other side.

Horizontal stitching progress is made by shoving the bodkin through the broomcorn AT AN ANGLE. With the first stitch done, we will now begin alternating with straight-through and diagonal stitching. Take the bodkin and shove it through the broomcorn BELOW the cross-broom-twine so that it emerges on the other side about 3/4" from the first stitch.

Now I will cross over the cross-broom-twine and push the bodkin through the broomcorn at and ANGLE BELOW the cross-broom-twine. Pull the twine through taught, and on the other side, just as before, cross over the cross-broom-twine and then shove the bodkin through STRAIGHT and ABOVE the cross broom twine. Then repeat, repeat, repeat, till you get to the other edge of the broom.

Finally, clamp the broom once again at the place where you want to trim the bottom. After clamping the broom corn, use a sharp stout shear or scissors to trim the bottom of the broom-corn. After 2 days remove the temporary windings holding the broom corn ends in place. Then happy sweeping!