August 2022

Building a fine wooden model of one of the most sailed little boats in the world: The Optimist!

The Optimist was designed in Clearwater Florida by Clark Mills in 1947. It is a simple and effective 7'-9" long sailing dinghy and over the years became one of the most sailed boats in the world! 150,000 of these have been registered and many more than built. The optimist has been used in 120 countries, and is a very popular youth training and racing sailboat. My two kids learned to sail on these here in Wisconsin.

Building the BlueJacket Optimist Dingy Model:

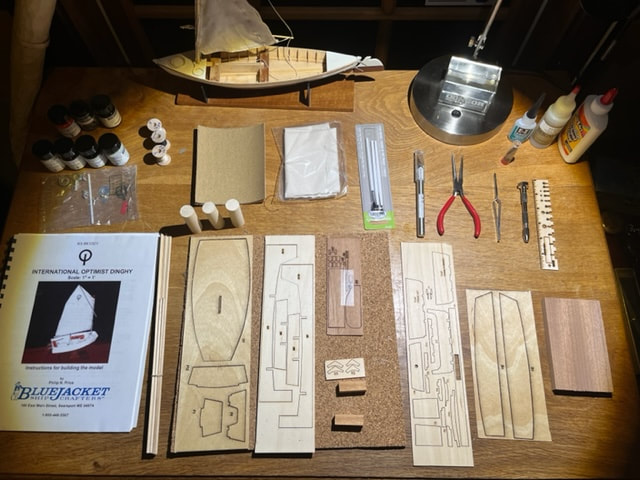

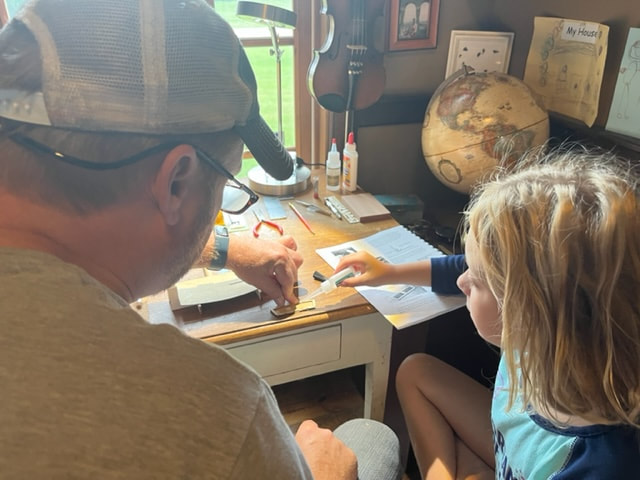

Just purchased and received the Optimist kit from Bluejacket. This is a beginners model meant for folks just starting in model building. I bought this as a model to build with my daughters, which I am looking forward to and I hope they enjoy it as well! Both of them sailed on Opti's so they have a connection to the boat. This is the first model I have built by BlueJacket and the kit has made a good first impression. The contents are well packaged contents, and as this is intended as a beginners first ship model, the kit includes a nice full size print drawing (not pictured) , glues, paints, pin-vise with drill bits, pliers, tweezers, razor knife, and all components needed for the build. Just opened up the box and I'm hoping to get started over the weekend

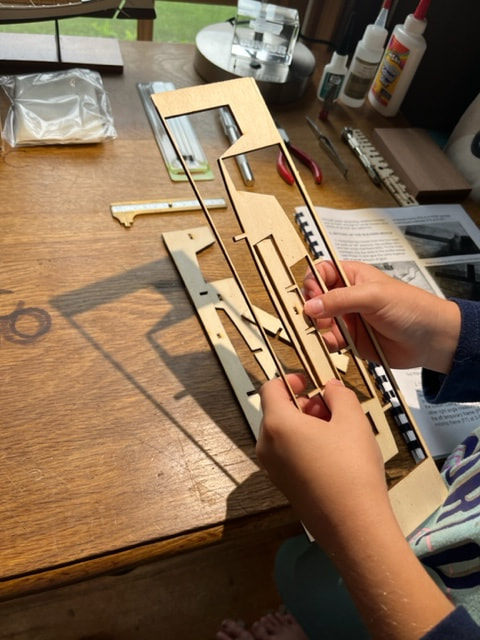

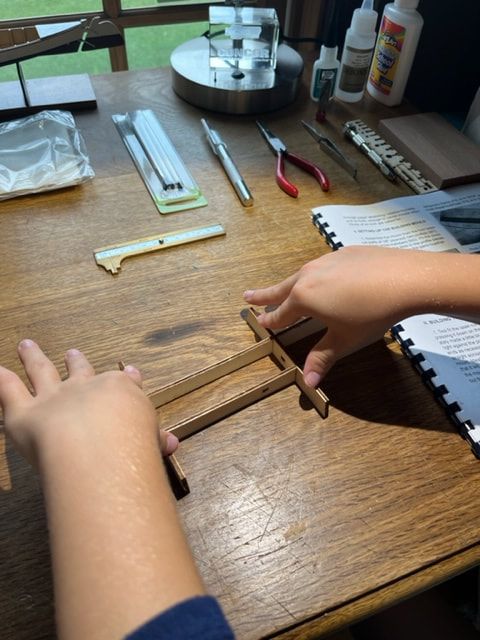

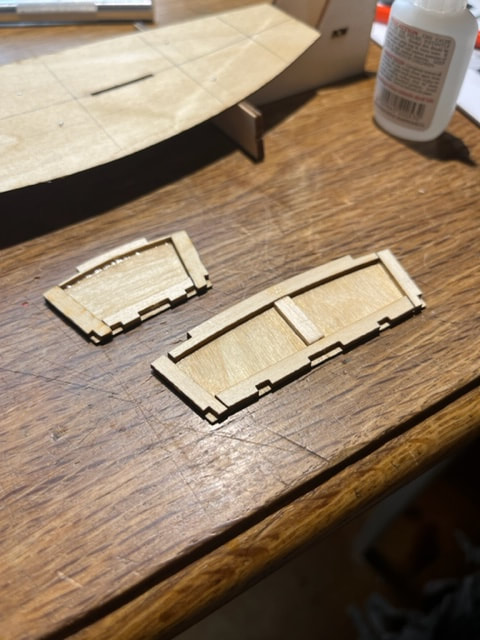

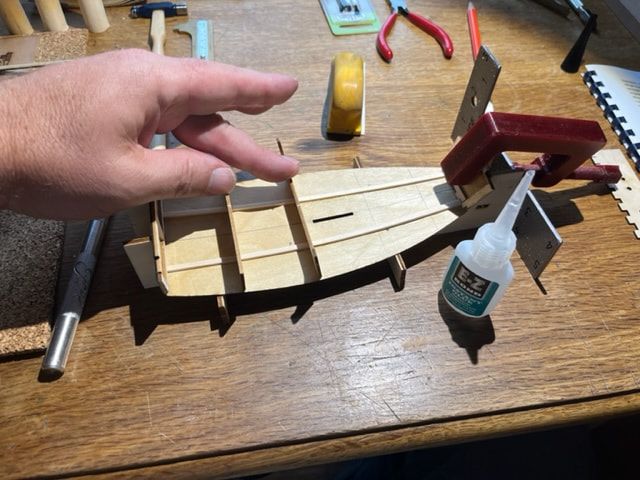

Here one can see the error of my ways regarding floor stringer spacing. The bulkhead closer to me when I took the picture is the temporary form. The bulkhead in the background is the one that will eventually support the mast thwart. The two narrow stringers running along the hull bottom are supposed to run through well fit notches in both those bulkheads, note that I had to cut the notches away into larger openings that fit the actual location of the stringers. Ultimately it won't impact the final model, but just be careful to put the spacers in the right place when you glue the floor stringers down.

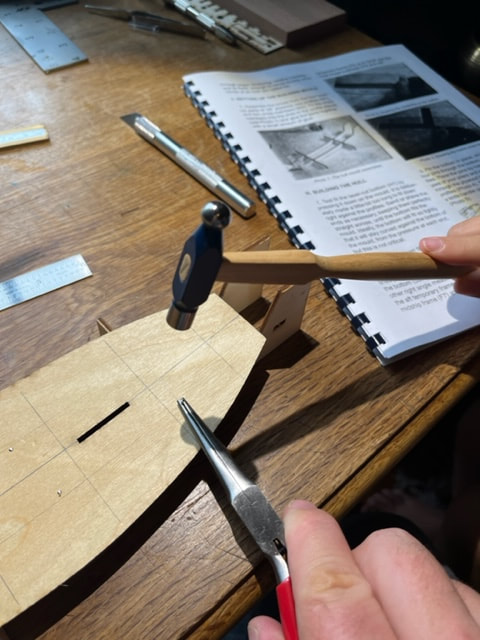

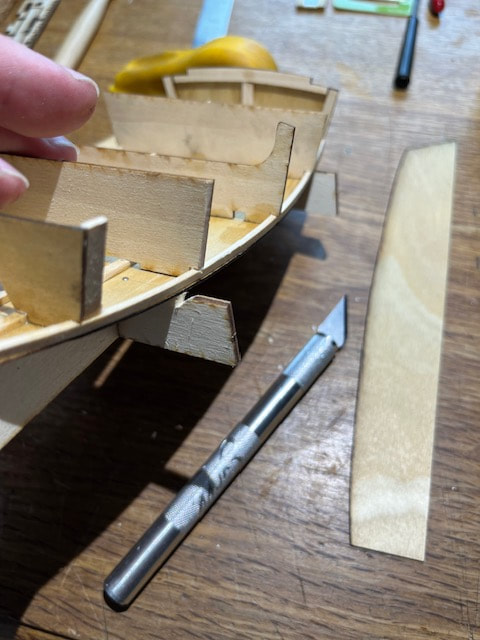

Mast Step Thwart and gunwhales installed. I painted the section forward of the mast thwart prior to installing the thwart, as it would be difficult to paint in there later. I cut the gunwhales to length first, then carved the ends to fit the corner gussets, then soaked them in hot water, then pre-formed them by forming them into a curved shape using pins and I cork board until they dried in a curve, then glued them into position. Nothing sanded yet at this point.

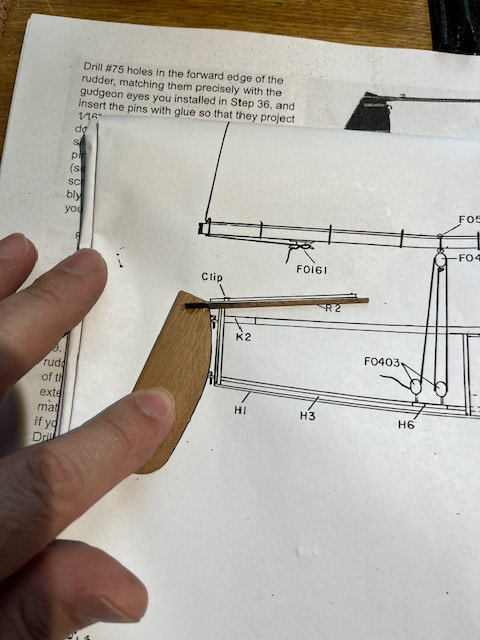

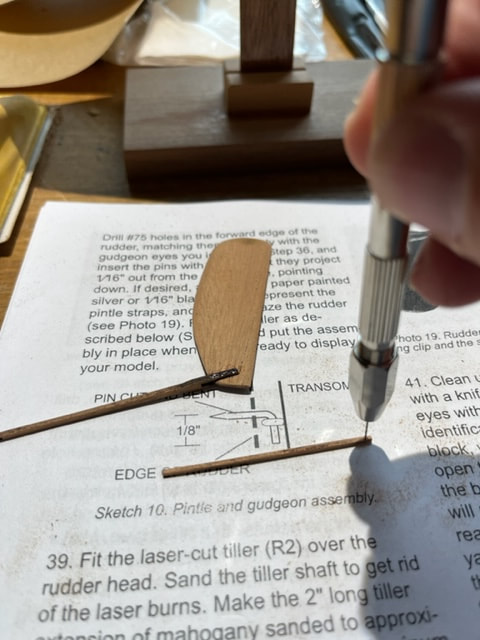

Starting work on the spars and rudder on this Optimist Sailboat Model:

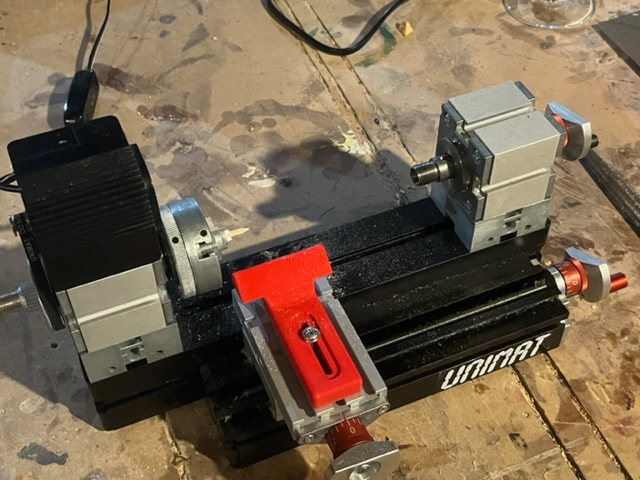

Little bit o work on the sprit tonight. The ends of the sprit on opti's are pin shaped for rigging. I shaped the pins by turning the sprit down at the ends on my mini lathe. I wrapped the sprit in paper to protect it from denting in the 3 jaw chuck, which worked well. Happy with results. This job could be done by carving down the end with a razor or by sanding it down with a file, but I like playing with tools so used my little lathe. Some photo's are below. I didn't even use the tool rest, I used a file and just held it up the the spar end to get the pin shape I wanted.

Completed , painted hull of model of Optimist Sailboat

Making the Sail for the Optimist Sailboat Model:

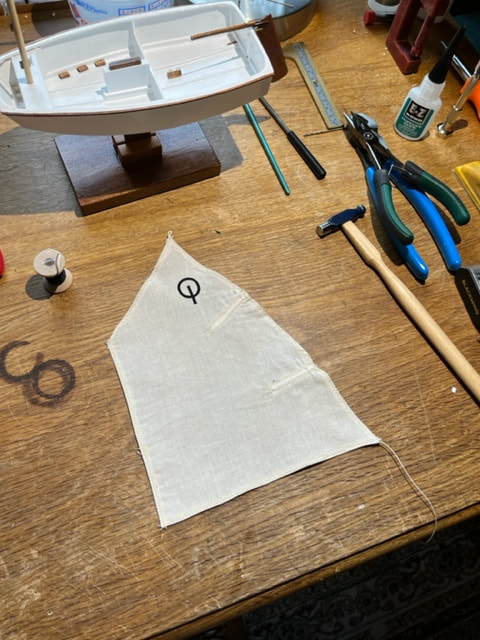

Well, I realized when I was done with the sail, that it was not the right shape. I had traced the sail shape along the sprit, not along what is the actual upper edge of the sail. So, I made a whole new sail to the right shape and got some more practice in model sail-making in the process.

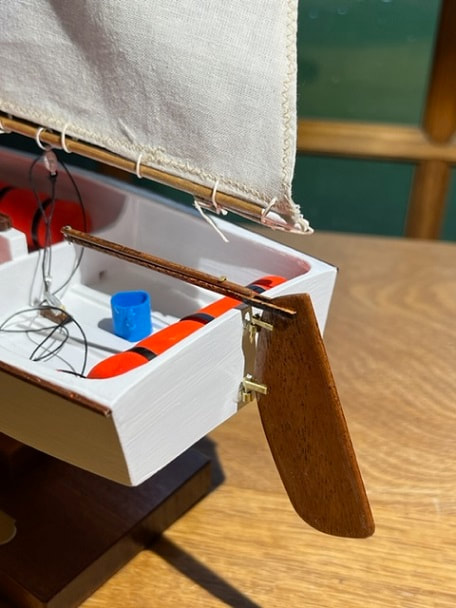

Below is a photo of the new, correct, sail. Note the boltrope sewn into the hems.

Below is a photo of the new, correct, sail. Note the boltrope sewn into the hems.