May 2023

A combination of two of my hobbies, Alphorns and 3D printing!! My largest printing project yet, a 12 foot long fully functioning Alphorn!

It's September 2, 2023 and I am considering this project complete!!!! I just finished the shortened version of the first section to tune it and raise the pitch a bit. Now I will play it and enjoy it. It functions well, though my wooden ones sound better , I think. There are a couple notes mid range that sound airy, so I may modify the design over time, but overall I am pleased. I will be taking it to a party later this month which will be fun. I will record a song on it and include it on this site.

It's August 12, 2023 and I just finished the horn and played it for the first time. It works!!! As you follow the build-log below, you will see it is a bit flat, so I will need to redraw and reprint the first section to raise the pitch a bit. The joints all worked and the horn plays! It is more flexible than a wooden alphorn, but the joints are very strong. I did a full destructive test on one of the sections by swinging it and smacking it against the corner of a wooden bench; it took multiple swings and when it broke, it did not break at the glue joint.

It's August 12, 2023 and I just finished the horn and played it for the first time. It works!!! As you follow the build-log below, you will see it is a bit flat, so I will need to redraw and reprint the first section to raise the pitch a bit. The joints all worked and the horn plays! It is more flexible than a wooden alphorn, but the joints are very strong. I did a full destructive test on one of the sections by swinging it and smacking it against the corner of a wooden bench; it took multiple swings and when it broke, it did not break at the glue joint.

Here is the build log of this 3D printed alphorn INCLUDING CAD DRAWINGS, but first; Photos of the completed Alphorn!

There are a group of people around the world who seek to create a 3D printed Alphorn. I have made 2 wooden Alphorns, also called Alpenhorns, and I set out to print a full size horn on my Prusa i3 MK3S 3D printer.

I drew a model of an Alphorn using Fusion 360, based on the hand sketches that I used to build my 2 wooden alphorns. I know that the design for my wooden alphorns works, so I think this design will work acoustically. For info on my wooden Alphorns, click this link.

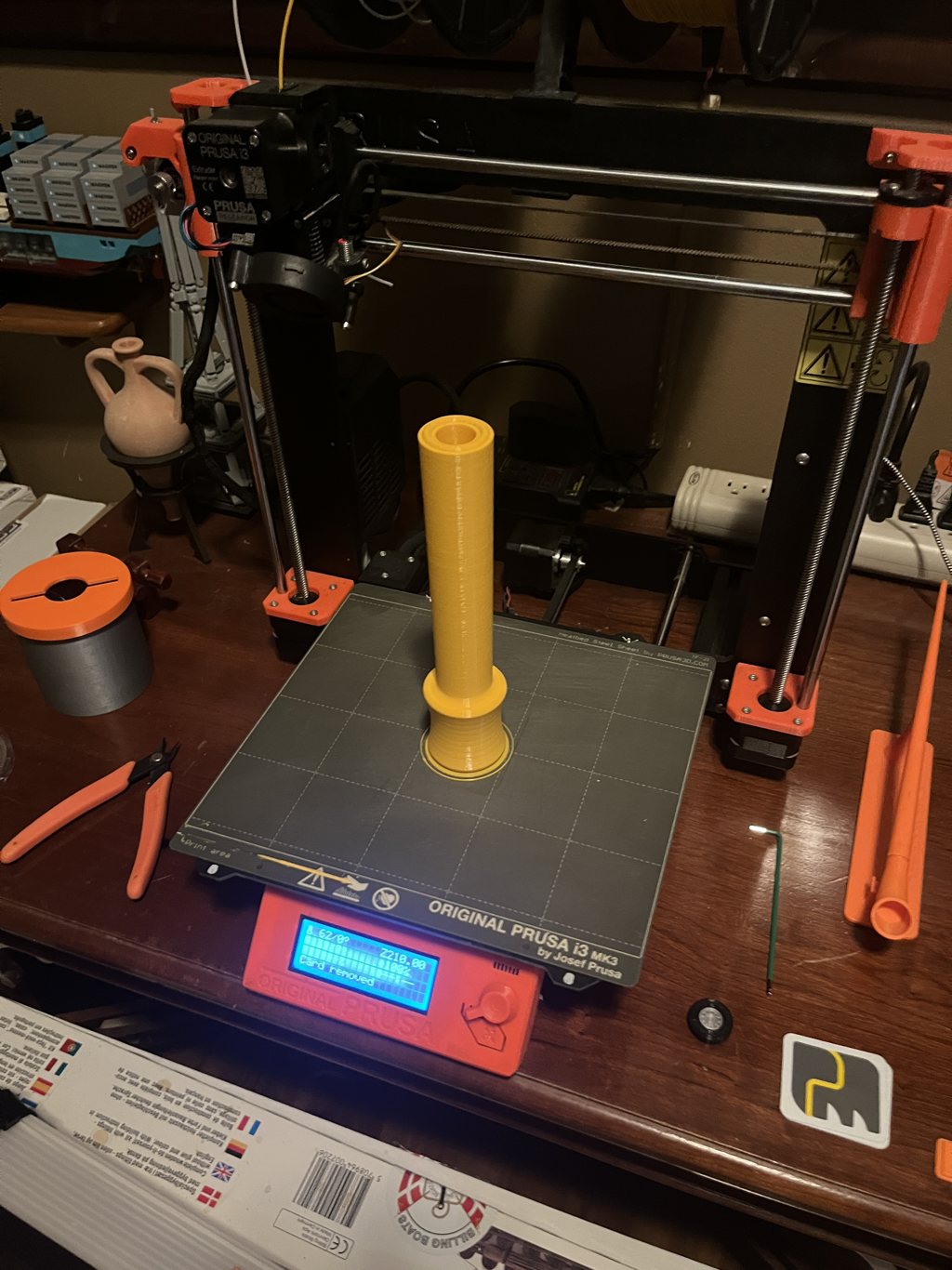

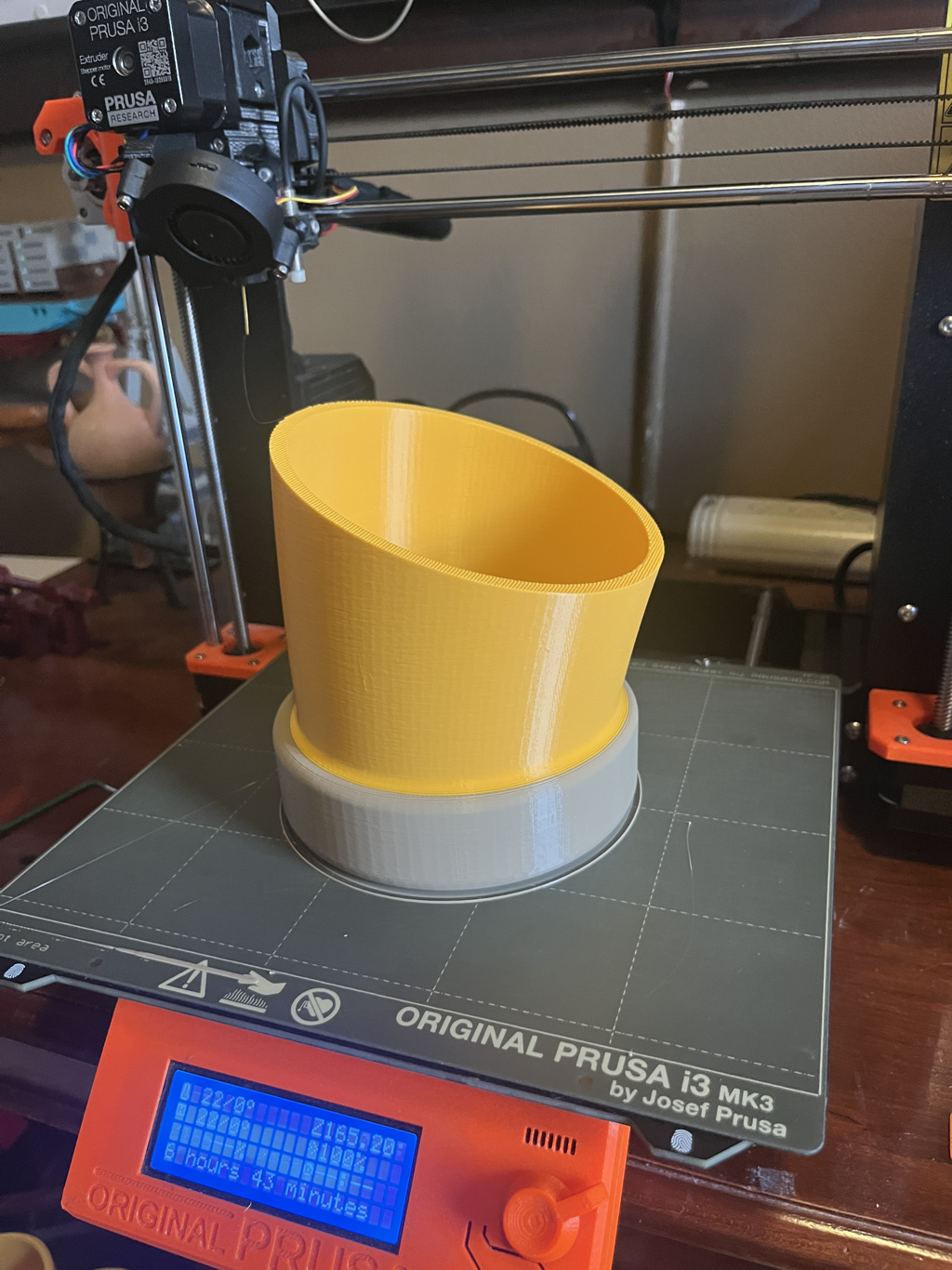

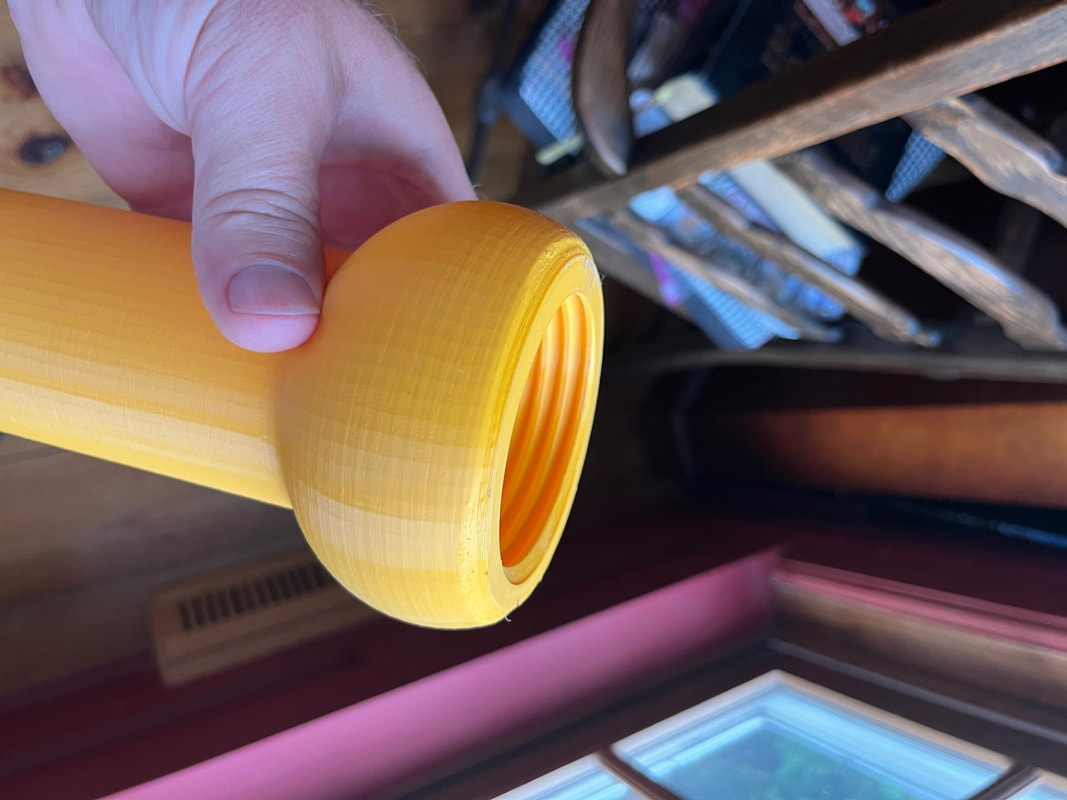

My 3D printed Alphorn needs to be able to be printed by my Prusa i3 MK3S printer, so I designed an Alphorn in 27 printed pieces. This Alphorn has been designed to break down into 4 pieces connected by 3 threaded joints. Other than the threaded joints, the other 27 pieces will be fused together with plastic epoxy.

CAD Drawings and rendered view of the 27 pieces

| 3d_print_alphorn_j_talbot_2023.f3d | |

| File Size: | 5232 kb |

| File Type: | f3d |

| alphorn_v20.ipt | |

| File Size: | 3506 kb |

| File Type: | ipt |

| alphorn_3d_print_j_talbot_2023.3mf | |

| File Size: | 2933 kb |

| File Type: | 3mf |

Fusion 360 render of 27 piece 3D printed Alphorn

Fusion 360 render of 27 piece 3D printed Alphorn

Maximum size of piece in this print

7.5" wide x 7.5" long x 8 1/4" high. 19cm wide x 19cm long x 21cm tall.

As of June 14 , 2023 I am in the process of printing the pieces , I am printing 2 pieces per day. Once I have them printed and once I prove the design and joints all work, then I will post my drawings/CAD model.

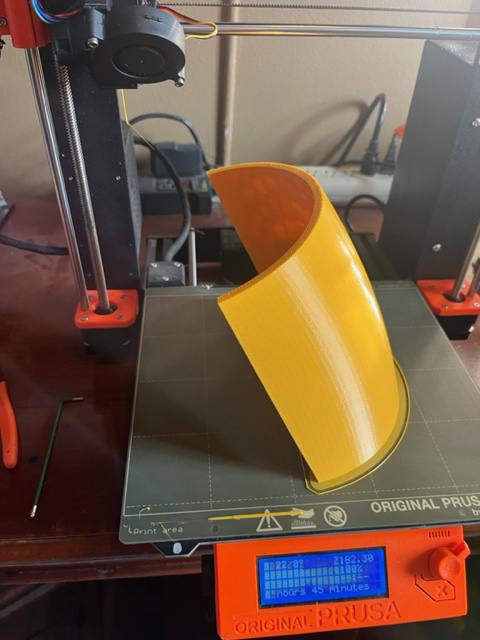

July 16 update. Apologies I was unable to print due to work commitments for a couple weeks so made not progress for almost 3 weeks. Back at it now and 3 more pieces to print.

July 17 update: All parts are now printed and I will begin epoxying the components together. At this stage I will find out if this whole concept will work or not!

July 16 update. Apologies I was unable to print due to work commitments for a couple weeks so made not progress for almost 3 weeks. Back at it now and 3 more pieces to print.

July 17 update: All parts are now printed and I will begin epoxying the components together. At this stage I will find out if this whole concept will work or not!

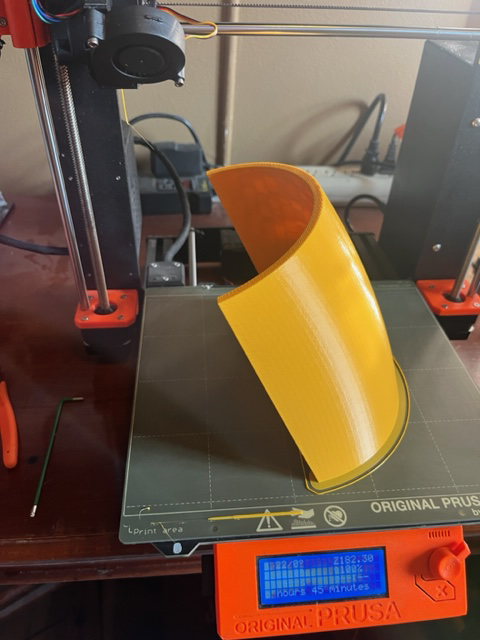

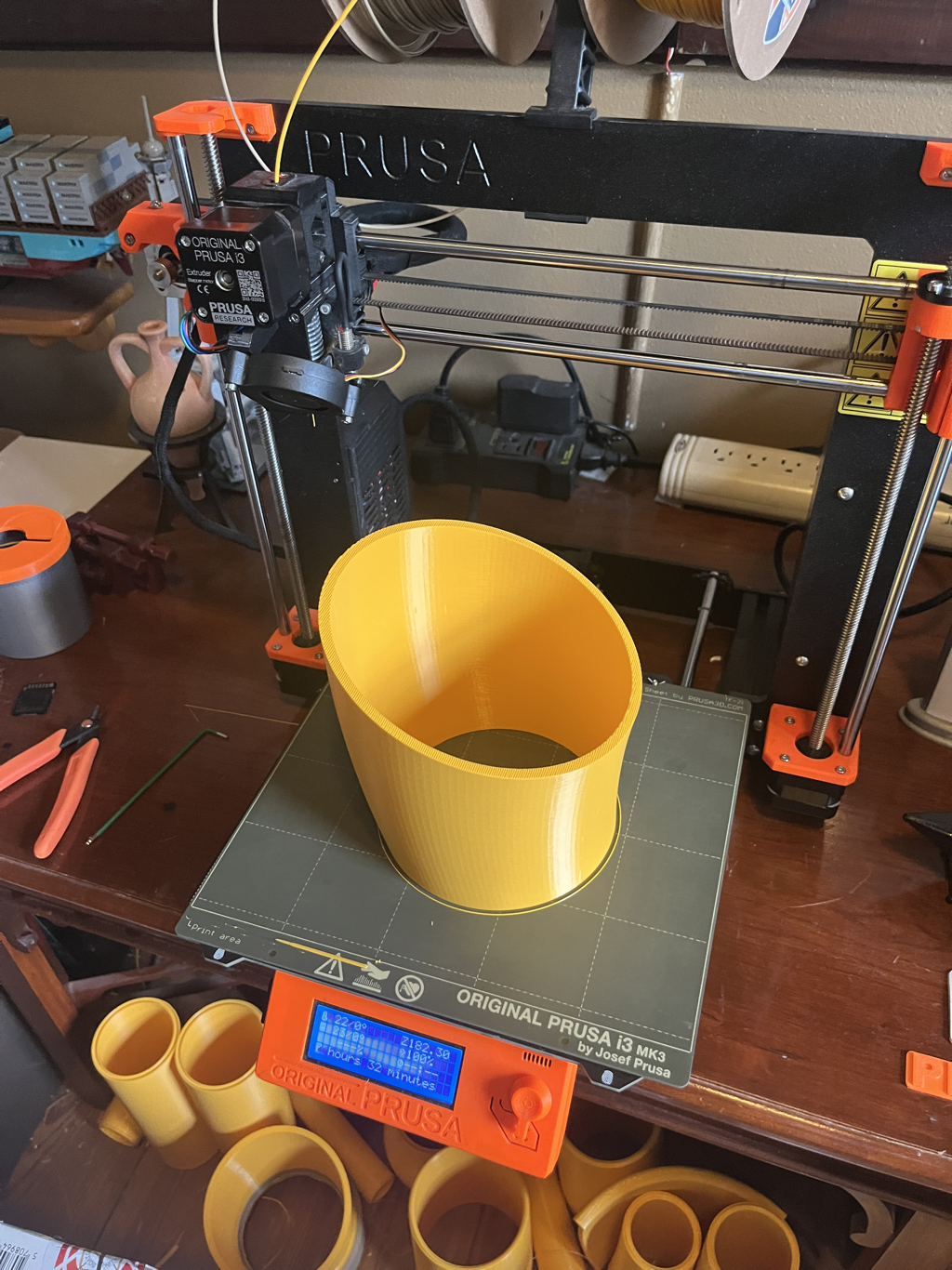

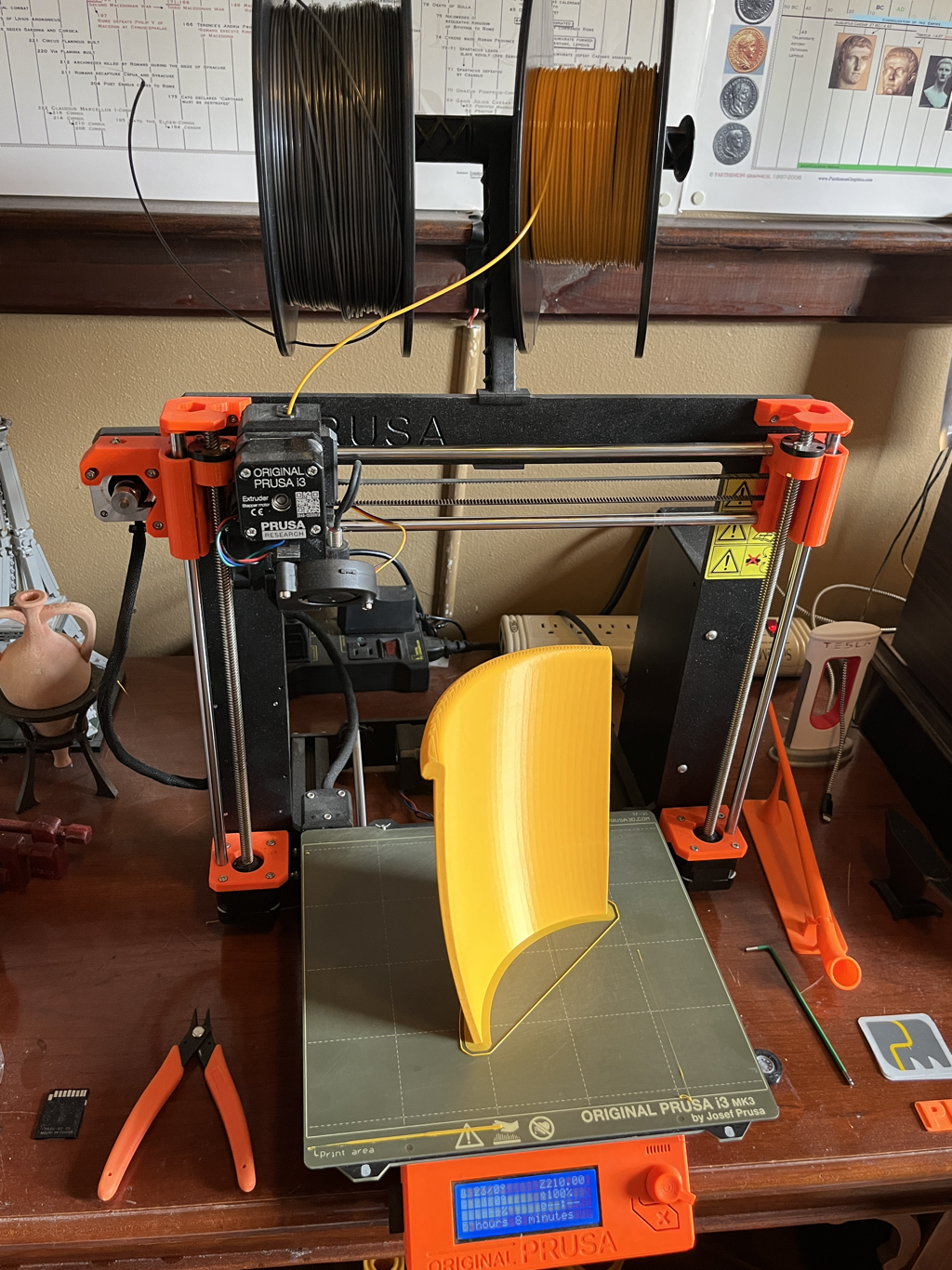

Printing the Alphorn:

Material: One could print this horn in various materials. I chose to print mine in PLA filament from Coex in Green Bay , Wisconsin.

Infill:

The Alphorn sections are printed in 25% infill for the first 5 pieces starting at the mouthpiece/skinny end of the horn , followed by 20% for the 2nd section pieces 6 through 10, then 15% for 3rd section pieces 11 through 15, and finally 10% infill at the bell end pieces 16 through 27. The foot I printed at 50% infill.

Supports:

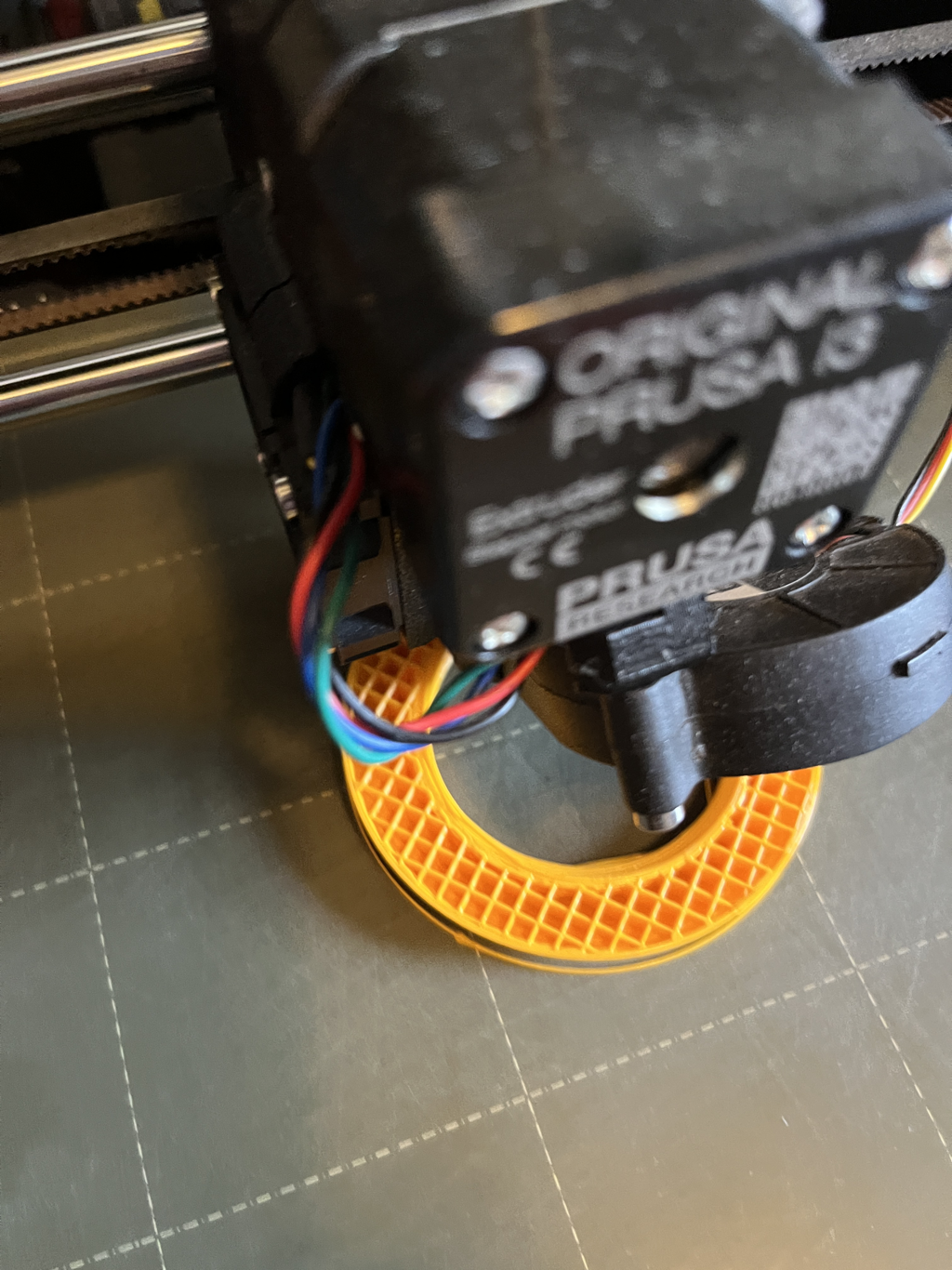

I designed the parts and sliced them on Prusaslicer including a brim but with no supports.

Resolution:

These parts were printed in 0.30mm draft resolution on my Prusa i3 MK3S Printer. EXCEPT pieces with internal threads, which I printed at .10mm resolution. I love my Prusa and the fine resolutions that are possible. I have never printed projects at the 0.30mm draft resolution until now. I am pleased with the outcome, and printing at this low resolution really shortened the print time.

Photos of some of the printed parts:

.....and now on to epoxy assembly of the parts!!

Assembling the 3D Printed Alphorn Pieces

Tuning the Alphorn:

Well, I finished the horn today, Aug 12, 2023. Wooden alphorns are tuned by cutting them to length with a saw. Below you can see the note "f" in three octaves played on this horn. It is a bit flat and probably needs to be about 4 inches shorter to be better tuned to F. I will need modify the drawing and reprint the first section!