above: Paddle boarding on a Kaholo SUP, Eagle Harbor Door County Wisconsin, July 2021.

I hope you enjoy this photo build log of the Chesapeake Light Craft Kaholo Stand Up Paddleboard.

Summer 2020:

We have enjoyed renting stand up paddleboards (SUP) in Door County over the years, and decided that we wanted a couple for our use near home. A bit of research led me to the Kaholo SUPs from Chesapeake Light Craft. It is a high performance, lovely looking, hollow frame wooden paddleboard that can be bought as a kit and assembled at home with simple tools. This will be for my wife so I am building the 12'-6" version, for myself, I would need the 14' model. I visited the Chesapeake Light Craft (CLC) shop a couple years ago. It is in Annapolis, a short drive from BWI, and it was fun to see the boards in-person, and also to see the high accuracy machines they have for cutting out kit components.

CLC Kaholo 12-6 Stand-up Paddleboard Specs:

Length: 12'-6"

Thickness: 4 1/2"

Width across the top of the board: 29 3/4"

Weight: 29 pounds

Construction: Hollow frame, Okuome marine plywood, stitch&glue construction with fiberglass and epoxy

Length: 12'-6"

Thickness: 4 1/2"

Width across the top of the board: 29 3/4"

Weight: 29 pounds

Construction: Hollow frame, Okuome marine plywood, stitch&glue construction with fiberglass and epoxy

The SUP Build Log is below, but first: I Made This Wooden SUP Paddle

The page you are on concerns the construction of a Kaholo wooden SUP. I built a wooden SUP paddle also. If you would like to see how I did that , please follow this link button:

Building a Kaholo SUP!

The Kit Arrives:

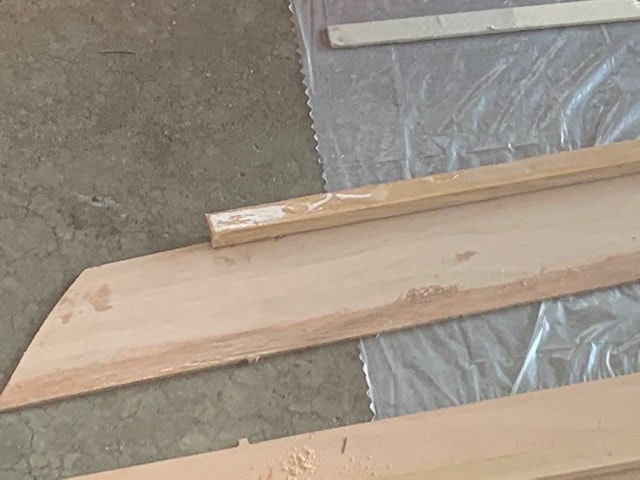

Gluing together the plywood panel pieces and the long wooden cleats

The kit comes with great photo instructions, which I will follow. Here I have laid out the plywood panels in the correct orientation, on a sheet of plastic in the garage. I have also cut out strips of fiberglass which will lay over the puzzle joints that join the big pieces of plywood together. Pick the side of the plywood that you want to show on the outside of your board, and face that side down. The side that is up at this stage, the side that get the fiberglass reinforcing strip, will be the inside of the board.

The start of building a Kaholo SUP has gone well! The pieces from CLC fit together nicely and the instructions are complete.

The Kaholo has two long solid wood strips that run down the length of the board on the inside top corner of the board. I will call these "cleats". There are two cleats, and they show up in the kit in two pieces each. To create a full length cleat, take two of the cleats and glue them together with the pre-cut "scarf" joint. The scarf joint is simply a long taper that increases the surface area of the glue joint. Line up the tapers and epoxy them together with silica-thickened epoxy. Do not over-tighten the clamps to the point that you squish all the epoxy out.

Weighted down the joints to keep them flush, with tiles and heavy objects. Note the plastic under the epoxy and the plastic garbage bags between the weights and the epoxied joints. The epoxy wont stick to the plastic. If you do not protect the adjacent surfaces using plastic in this manner, you will likely glue the plywood to the floor and to the weights.

So far the CLC Kaholo SUP kit has been a breeze to work with and the components have fit together perfectly.

Cutting the long solid wood cleats to length

The Kaholo 12-6 has solid straight grained clear wood cleats that run from end to end in the corner between the deck and the sides. I epoxied the scarf joints together to create full-length pieces, and now I will trim the end to the correct angles and length as described in the manual.

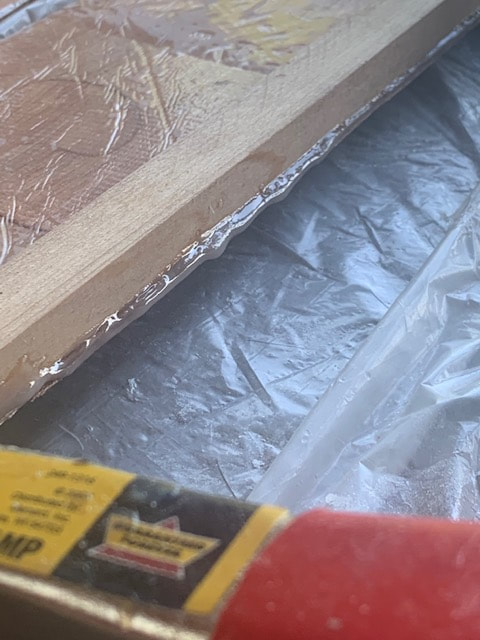

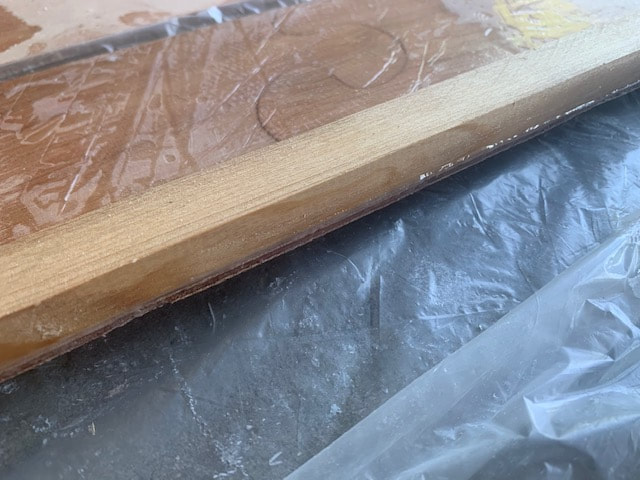

Epoxying the cleats to the side panels

I rasped and sanded down the high spots of epoxy that existed where I had laid down the fiberglass reinforcing strip on the sides. I also rasped and sanded the scarf joint area on the cleats so that the joint sides were flat and sanded. This will ensure nice flush surfaces for glue adhesion, and sanding the epoxy also creates a rough surface, called a "key", for the epoxy to sink its teeth into for a better bond. The kit came with slow-cure epoxy, which is good for long pieces like this. Fast set epoxy might start curing before one was ready to clamp the pieces together, especially in summer like what I am in now.

When I built my SCAMP sailboat, I quickly learned that cleaning up epoxy BEFORE it cures is SO much easier and saves SO much chiseling, sanding and rasping vs if it is left to cure in a messy fashion. In this photo one may see the epoxy ooze-out from clamping the cleat to the sides. Now is a great time to take 45 seconds and run your gloved finger down this glarpy epoxy and make a nice tiny smooth fillet out of it.

Fiberglassing the Underside of the Kaholo SUP Deck

There appears to be enough fiberglass in the kit to complete the build of this Kaholo SUP. Not sure if they included enough epoxy though.

I mixed slow set epoxy in 12 ounce batches and applied it from the center out. Spread the fiberglass out nice and flat from the center out, eliminating any air bubbles. I used a chip brush, but a epoxy spreader works great also. The fiberglass will absorb the epoxy and turn clear, this is called "wetting out" the "glass". Apply enough to "fill" the fiberglass, but not too much where you have excess epoxy floating over the fiberglass sheet.

Stitching together the bulkheads and sides of the Kaholo SUP

This was an exciting part of the Kaholo Stand Up Paddleboard construction, as it really starts to take 3D shape!

Stitching the bottom panel onto the Kaholo 12-6

First, I put the bottom panel in place over the bulkheads. The bottom of the board is still facing upwards. The fiberglass reinforcing strip on the bottom panel puzzle-joint will face the inside of the board. My wife and I did this whole step together. Before we began stitching the bottom panel to the board, we stitched the split forward section of the bottom panel together.

Chesapeake Light Craft has done a nice job in my opinion of designing and cutting out the pieces for the Kaholo SUP. The pieces continue to fit together well.

With the board right side up, we twisted the wires that we had pushed through the bottom earlier. These hold the bottom tight to the bottom of the bulkheads. The wires we long enough, and we found it much easier to just run these through the big holes in the bulkheads, not the little pre-drilled stitch holes.

Truing up the board, epoxying the joints, and removing stitches.

Next I mixed thickened epoxy to a still-fairly-thin consistency , so that it could be drawn up into a syringe. We then used syringes to apply epoxy glue to all the joints, doing our best to skip over the copper stitches. After a day of curing, we will remove the wires, and then we will have more epoxying and filleting to do.

Filleting the joints

The joints which were stitched and glued together are now further reinforced with a "fillet" of epoxy which has been thickened with wood flour. These fillets are not unlike a fillet weld in metal welding, as they form a roughly triangular-in-cross-section reinforcing support and bonded joint between two pieces of material. If you can plan it, just do the filleting the next day and you can skip the sanding, in my opinion.

Important: Here you can see the epoxy glue which was applied earlier to the joint. IF you apply the fillet over this epoxy within about a day and a half, the epoxy fillet material will still chemically bond to this epoxy glue. IF the epoxy glue cures completely hard and shiny, then it will present a slick surface that your epoxy fillet will not bond well to. Anytime you want to epoxy together two epoxied surfaces that have already cured, you need to rough up the surfaces to provide a "key" or roughed up surface for the new epoxy to grab on to. It has been over a week since I worked on this SUP, and you can see the glossy hard, completely cured glue in the corners. I will rough this up with 120 grit sandpaper so that the fillet bonds well. If you can plan it, just do the filleting the next day and you can skip the sanding, in my opinion.

With gloved gluey hands I didn't get good pictures of this step....but: 1. Mix about 18 oz of epoxy and thicken it with wood flour until it is so thick that it will not drip off of the stir stick. 2. Transfer the mixture to a disposable backery piping bag , or a large ziplock. 3. Cut a 1/4" to 5/16" hole off the bottom corner of the bag. 4. Squeeze the mixture into the corners of all the joints in the SUP. 5. Use a stick that looks like a large tongue depresser, 1" wide, with an end that is cut to a 1/2" radius semi-circle. USe this semi-circle-ended paddle/stick to form a nice concave bead or fillet in the material that you have squeezed into the joint corners. IMPORTANT: We did this today and it's about 73 deg, and the kit comes with SLOW cure epoxy. If you mix a big batch of epoxy like this with fast cure or even medium cure epoxy, especially on a hot day, you will have a hot, smoking, and fast curing pot of epoxy that will cure before you can use it all. Epoxy cures in an exothermic reaction, giving off heat, and I have mixed even medium size batches in very hot weather than started smoking because they got so hot; not good, and you waste the epoxy. All that said, it's not too hot today, and this is slow set epoxy so we used 34 ounces of epoxy to fillet the whole Kaholo 12-6. About 18 ounces per batch.

Well I got slowed down at this point by an unplanned surgery. In September I will restart the project!

Building the Kaholo SUP: Epoxy Coating The Interior, Installing the Stringers and Handle Reinforcers

Feeling better and getting back to work on the SUP today, Aug 29, 2020"

I coated the stringers with unthickened epoxy, including flooding the long "endgrains" of the plywood which soak up more epoxy. Then I used left over thickened epoxy from gluing the bow piece in place, to fillet the stringers with my finger. I would normally make fillet material with wood flour, but I had left over silica-thickened epoxy which worked fine.

Laminating The Transom

First I sanded the plywood aft facing surface of the rear transom. Then I gave it a coat of unthickened epoxy, then I gave it a coat of silica thickened epoxy and then I applied the walnut and pine strips from the kit in an alternating pattern. I was sure to give all glued faces of the strips a good coat of epoxy glue as I went. I clamped them and taped them in place to cure. The wooden braces I am using with the clamps, are covered in clear plastic packing tape so that they do become adhered to the transom.

Attaching The Top To A Kaholo Stand Up Paddle Board:

This is a big step!!! Once one attaches the top to the board, one will never see most of the inside of the board, or have easy access to the inside of the board, again. It is also imperative to have ample weights and tape at the ready.

*Note, at this point I ordered a quart and pint of additional MAS resin and hardener (slow) from CLC. It would be disastrous to be gluing down the top or wetting out the fiberglass on the board exterior, and then to run out of epoxy mid-step. I don't think there is enough epoxy or silica left in the kit to make it (there is plenty of wood flour left). I wasn't perfect with my epoxy, though I wasn't overly wasteful either, and I do not think there is enough left so I bought some more.

*Note, at this point I ordered a quart and pint of additional MAS resin and hardener (slow) from CLC. It would be disastrous to be gluing down the top or wetting out the fiberglass on the board exterior, and then to run out of epoxy mid-step. I don't think there is enough epoxy or silica left in the kit to make it (there is plenty of wood flour left). I wasn't perfect with my epoxy, though I wasn't overly wasteful either, and I do not think there is enough left so I bought some more.

- I missed a key photo here: I sanded the tops of all the upward-facing edges that the top will glue down to, so that they would present a nice , flush, rough surface for the epoxy glue.

Vacuuming out ALL dust and debris from the interior of the board. I figured this was my last chance to make sure any objects were removed from the board prior to me gluing the top on. You'd hate to have something rattling around in there for all time and to be unable to remove it later. I vacuumed the heck out of it and also vacuumed the top edges where the top needs to adhere.

- Next I mixed unthickened epoxy and brushed it into the bare upward-facing edges of the frame. The unthickened epoxy will soak into the unfinished edges better than thickened epoxy. With that done, I immediately made a large batch of thickened epoxy and applied a thick bead of epoxy to all upward facing edges of the SUP frame. I made this epoxy glue paste thick, otherwise it will drip right off the tops of the edges....it needs to be thick enough to stay put.

Planing and sanding the board down prior to fiberglassing

After sanding with 80grit, I vacuumed the entire board to check for voids in the exterior seams. The seam between the top and sides was full of epoxy due to how the top was glued down onto a thick bed of epoxy glue. The exterior joint seams of the sides to the bottom had been epoxied and filleted from the inside, but needed to be filled in spots from the outside. At this point in the build, I filled any of those voids with silica thickened epoxy.

Then sanded the entire exterior of the board with 120, 180, and finally 220 grit, with a random orbit sander.

Fiberglassing the Bottom of the Kaholo SUP

The Kaholo comes with a breather to let the interior of the board dry out and also to ensure that a pressure differential doesn't build up between the inside of the board and the outside. With the next step being to fiberglass the bottom of the board, I decided to drill a small 1/8" dia hole in the deck where the breather will eventually go.

This step was not in the OEM plans. A day after applying the single layer of fiberglass on the bottom of the SUP, I epoxied on a 5" wide second layer of fiberglass on the sharp bow and down the bottom of the hull as shown in the photo. At this time I also applied a complete 2nd coat of epoxy over the previous days fiberglass/epoxy which had not yet fully cured.

Attaching the fins to the bottom of the Kaholo SUP

First a sanded down the area where the fins will be glued to the bottom, with 120grit sandpaper to rough it up. I elected to use "Bamboo Twin-fins by True Ames" which I purchased from the CLC site https://www.clcboats.com/shop/products/new/gephart-bamboo-fin-set.html These fins look cool and are fiberglassed at the manufacturer.

I made a square and true fixture to hold the fins staight and vertical during glue up. The bottom of the board from the kit has two marks that mark where the leading edge of the fins should start, then it's up to you to make sure they are straight fore-aft and vertical. I glued these to the bottom with epoxy thickened with silica.

- At this point, I sanded all the bottoms and sides, and trimmed the fiberglass and sanded the fins. This took a while, I did this with 120grit on a random orbit sander.

Fiberglassing the top of the Kaholo SUP

Fiberglassing and epoxying the bottom and sides, resulted in drips on the nice radius around the top of the board. I resanded this to recreate my nice smooth radiused top edge. With that done I was ready to fiberglass the top.

- aaaaaaand now the sides are all covered with epoxy drips again so it's back to rasping and sanding. 120 grit then 220 grit. Top and sides.

I have done this project at quite a relaxed pace and now it is autumn and freezing at night and soon is will be freezing all day. From here on out I need to turn the garage heater on to keep it over 55deg in the garage , for epoxy and paint and varnish to dry.

- With the deck hardware laid out (not permanently installed!) I was able to lay out the graphics. This board is for my wife and being of Norwegian decent, she had requested some rosemaling. I had made some stencils for a project a few year ago, based on the rosemaling in Disney's "Frozen", and she liked those, so I reused the stencils for this project. The original artist who drew these designs for Disney, is Brittney Lee, thanks for the wonderful art, Brittney!