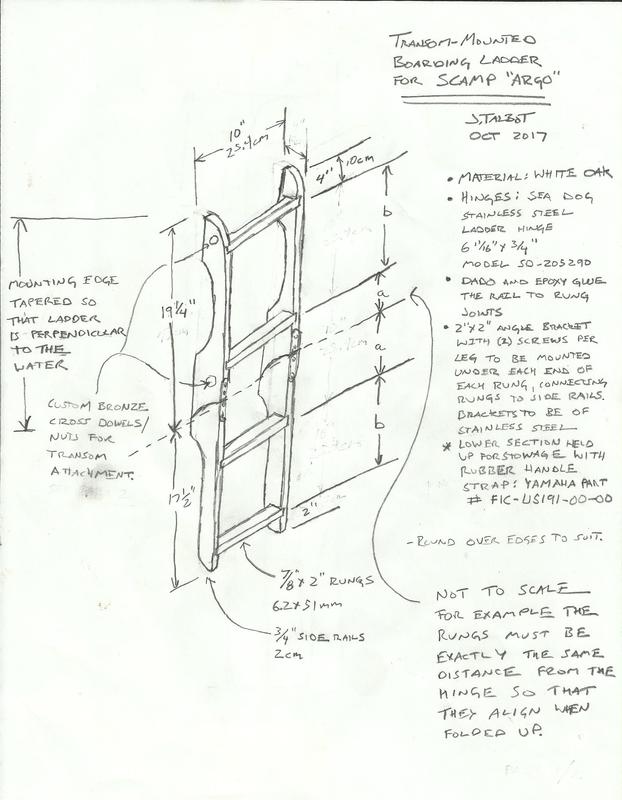

Argo will be fitted with a white oak, folding, transom-mounted boarding ladder.

The boarding ladder is useful for re-entering the boat which is an important safety feature. It will also be useful for kids and adults to re-enter the boat after taking a nice swim.

As an engineer, I must admit, this is a poor drawing, not to scale, and the dimensions are not even exactly right. This was my concept sketch and during the construction of the ladder I measured and built it right. Apologies for the shoddy drawing, do your own planning, the concept sketch above is a decent reflection of what I built, just not a good reliable construction drawing.

Mounting Hardware

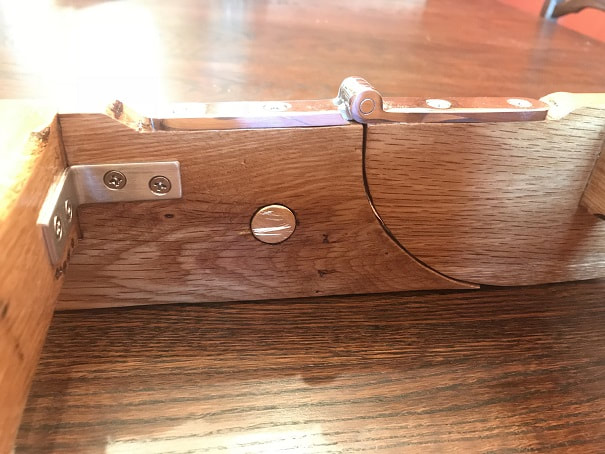

- The ladder will be mounted to the transom with four 1/4" diameter through-bolted machine screws. These machine screws will thread into 3/4" diameter cross-dowels that will be fitted into the ladder rails.

The white oak, as with other white oak used on this project, is from an old tree that fell down in the yard a long time ago. Many boards to not have milled edges, as seen here. First order of business is establishing a straight edge. I marked a straight line as can be seen, and cut to it with a saber saw.

IMPORTANT DESIGN NOTE!!!!!!: I was laying in bed pondering my boarding ladder in the wee hours of the morning, and as I looked through pictures of SCAMPs and boarding ladders, it sank in that the transom of the SCAMP is not perpendicular to the water.....in fact it has a aft leaning angle to it, such that the top of the transom overhangs the water a bit. Climbing up a reverse incline such as this would be a chore.....so I got up and cut an angle into the upper portion of the ladder that mounts to the transom. Luckily, I started with 4" wide rails, so I had enough room to add a nice taper with enough room to still get your fingers around the upper rung.

- Made 3/4" x 3/4" backing strips that will reinforce the transom on the inside of the transom; the mounting hardware will go through and be tightened up against these strips on the inside of the transom. They are the full length of the upper section of the boarding ladder, I may need to trim them to fit during installation.

- Removed hinges, sanded everything, and applied 6 coats spar varnish.

Boarding ladder thoughts specific to this SCAMP: I find the boarding ladder on my Compac 16 very useful for entering the boat from the water. On small boats, boarding from the side will tip the boat substantially, whilst boarding from the stern, especially as near to the centerline as possible at the stern, provides a stable reentry point. That is based on reasonably calm waters, re-entering a boat that it upright. Re-entering, or righting, a boat that is on its side, or turned turtle, is another situation entirely; For this reason I will be installing both mid-ships re-boarding stirrups along with this boarding ladder.