I modified a small jon-boat trailer to fit the unique shape of the SCAMP hull.

The bottom of the boat is flat from port to starboard, but has a belly from stem to stern. The bow is a vertical, flat, pram bow. I considered the following:

- The flat skegs would make resting the boat on a solid platform quite easy, and if the platform were big enough, you could even walk around the boat on it. I decided against a solid platform, as I did not like the idea of damp dead air between the platform top and the bottom of the boat. I wanted a more ventilated system, so I stuck with carpeted bunks.

- I wanted large surface areas on the bow roller and bottom-support pieces, so I removed the stock urethane rollers and made large flat carpeted support blocks as shown below.

SCAMP Bow Roller / Bow Support

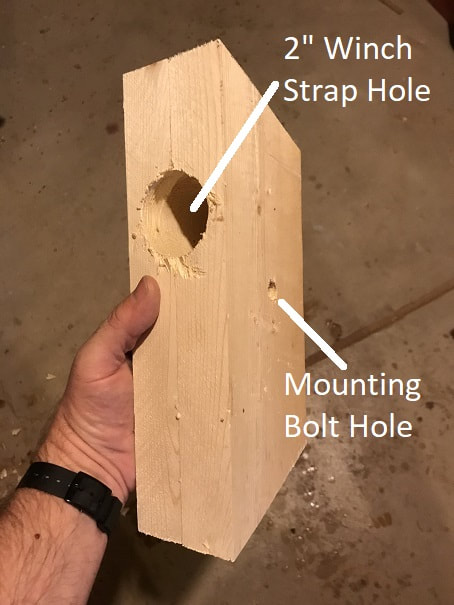

I used scrap 2x6 lumber to build a flat-faced bow support piece to sit flush on the pram bow. It has a large hole drilled through it, through which the winch strap runs, and it is covered in trailer-bunk-carpet.

I used a 2" forstner bit to bore a large hole through the piece. I also drilled a pivot bolt hole which will be used to mount this block to the bow-roller-bracket on the trailer. Be sure to avoid interference between the mounting-bolt hole, and the winch-strap hole. The way my winch, and probably most winches, are set up, is such that the winch-strap hole is located above the pivot bolt hole.

I adjusted the vertical position of the bow-roller/winch on my trailer all the way up to the top of the post. Here you can see the bow-support installed. The winch strap passes through the hole and when tightened, draws the boat up flush to the flat bow support piece. Be sure that your winch hook and bow-eye fit into a 2" hole. The bow support piece is snug but not tight, it can pivot a bit so that is always sits flush against the bow.

Bow Bottom Support Piece

As with the bow-roller, the stock trailer came with a urethane roller in this bracket. I made a large flat carpeted support-piece with a beveled leading edge, and installed it in this location. The original roller can be seen in the photo up at the top of the page. I like a larger surface area to make contact with the plywood bottom, rather then a winged roller.

SUPPORTING THE SCAMP'S CENTERBOARD WHEN TRAILERING:

I'd say it is important that the centerboard is firmly supported from below when trailering, rather than relying on the centerboard-uphaul-tackle. The arrangement I used above, results in the trailer bunk being directly below the centerboard case, so the centerboard rests right on the trailer bunk.

I'd say it is important that the centerboard is firmly supported from below when trailering, rather than relying on the centerboard-uphaul-tackle. The arrangement I used above, results in the trailer bunk being directly below the centerboard case, so the centerboard rests right on the trailer bunk.

Trailer Bracket for Transportation and Storage of Outboard Motor

- To avoid the weight of the motor bouncing on the transom during transportation, and to provide a convenient long term storage spot, I built the bracket below on the trailer. I have used a similar bracket on the trailer of my Compac 16 for years.

- Use U-bolts to avoid drilling through the trailer frame.

1. TWO U-Bolts (the gape should match your trailer tube height and the length should be long enough to go through the boards and across the tube) 2. Stout bracket board (On my other boat I used a 2x10, this time I didn't have that but I had some left over 1.25" hardwood, so I used that) Make it as short as possible but long enough to keep good clearance between the skeg and the ground; you will need to measure your motor. 3. I used a backer board for the other side of the tube from the bracket board.