SCAMP ARGO's Birdsmouth Mast is made from Sitka Spruce. Construction photos below.

The plans call for a hollow wooden mast made using "birdsmouth" joints. It makes for a strong, light, and quite pretty mast. The hollow design minimizes weight aloft and makes stepping the mast easier due to the overall lighter weight. The joint looks complicated, but I think it will be worth it, and also not too difficult, so I will go for it. Tools required are: surface planer, a decent table saw, handplanes, good straight edges, and a nice area to work on pieces that are over 16' long. If you don't have a surface planer, I imagine you could take your boards to lumber yard or cabinet shop to have the initial thickness-planing done. The procedure I followed is detailed below, and detailed photo's of each step are below.

- Cut the boards to length; and I left an extra 2" longer the final length for this initial rough-cut

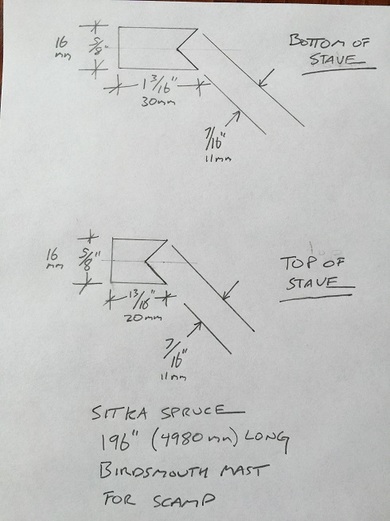

- Used a surface planer to plane the boards to 5/8" (16mm)

- Rip 8 staves. I ripped the rough blanks to 1 5/16" which is slightly oversize vs the finished dimension at the bottom of the mast for each stave which is 1 3/16" (30mm)

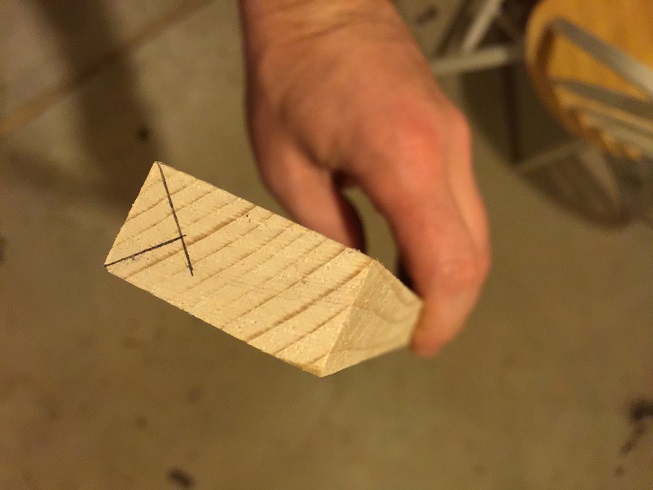

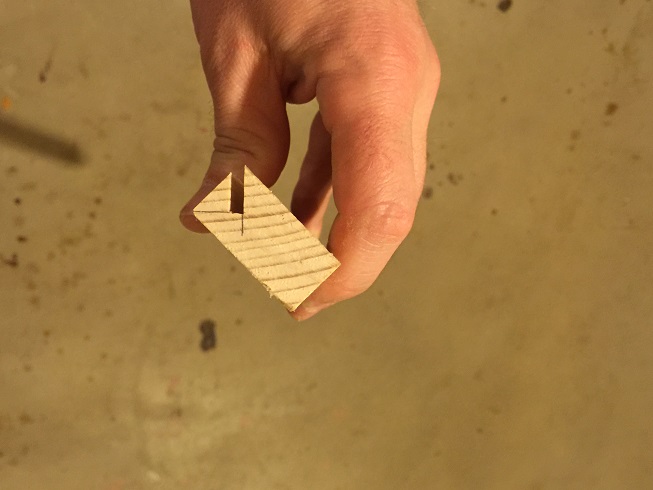

- Cut in the birdsmouth using a table saw (detailed steps below)

- Measure very precisely using stainless steel rulers and squares, and a frequently-sharpened pencil, and mark the tapers onto the staves. NOTE that the taper-rate increases near the head of the mast. The taper is not constant from base to head of the mast. I used the taper dimensions provided on the purchased SCAMP drawings and connected the dots with a fine straight 36" stainless straight edge.

- I used a saber-saw with a new sharp blade to rough-cut the tapers, and then sanded them exactly to the marked line, this worked quick and worked well. I dry fit the assembly and it looks great. Now I will not get back to this project until the weekend.

- Detailed photos of steps are below

6. Now adjust your tablesaw fixture for the second birdsmouth cut. The stave will lay with the wide side down on the second cut, as you can see in the photo. Adjust the depth of cut and fence locations and cut your test piece first to make sure it is perfect. Then cut the second cut of the birdsmouth into all the staves.

8. Measure very precisely using stainless steel rulers and squares, and frequently sharpened pencil, and mark the tapers onto the staves. NOTE that the taper-rate increases near the head of the mast. The taper is not constant from base to head of the mast. I used the taper dimensions provided on the drawings and connected the dots with a fine straight 36" stainless straight edge.

12. Enlisted my wife to help jostle the pieces together and held them in place with zip-ties. Photo above is after zip-tying the mast together. Zip ties about every foot or less. I then went over the whole mast with epoxy to fill and gaps in the joints, but I had good epoxy filling the birdsmouth so I think this will be very strong joinery.

- Proceeded to apply 3 coats of epoxy followed by 4 coats of Epifanes high gloss spar varnish.

Leathering the SCAMP Mast

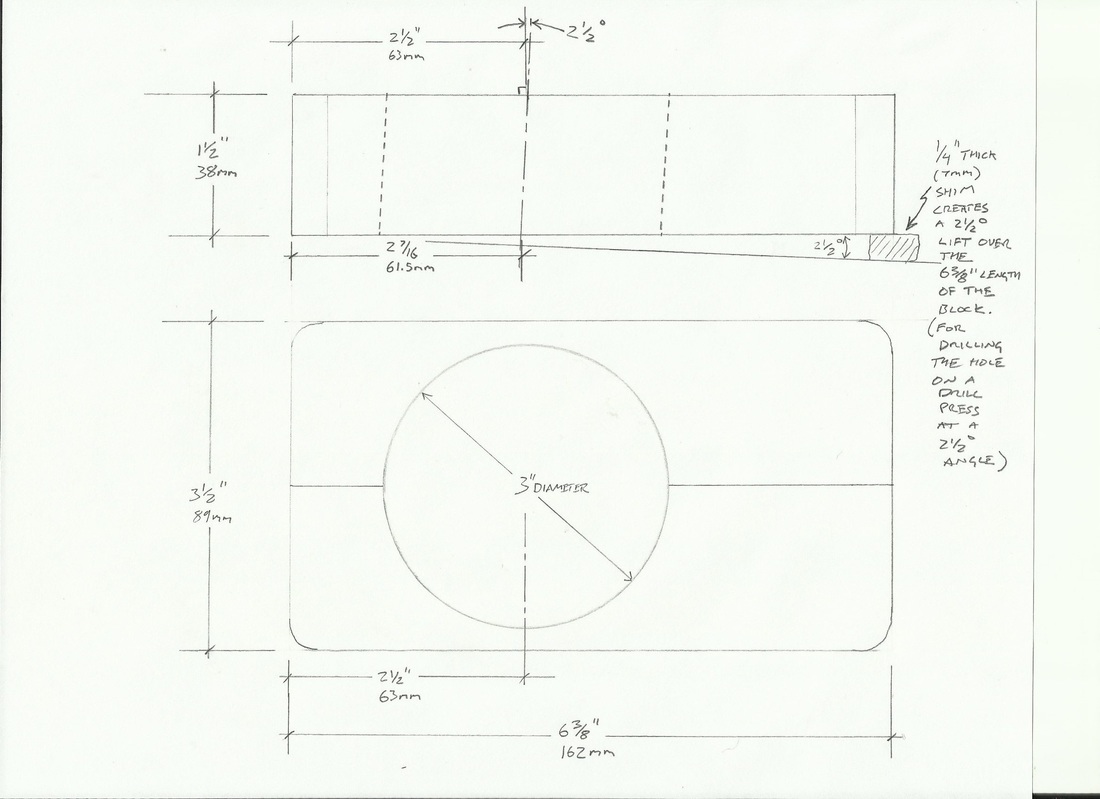

- I bored a 3/8" diameter hole in a short length of hardwood 3/4" dowel. Then I drilled a 3/4" hole in the top of the mast and epoxied this bored-hardwood-dowel into the mast. Epoxied the dowel inside and out. This 3/8" hole through the mast will be used to attach the halyard block and to provide an attachment point for topping lift/lazy-jacks.

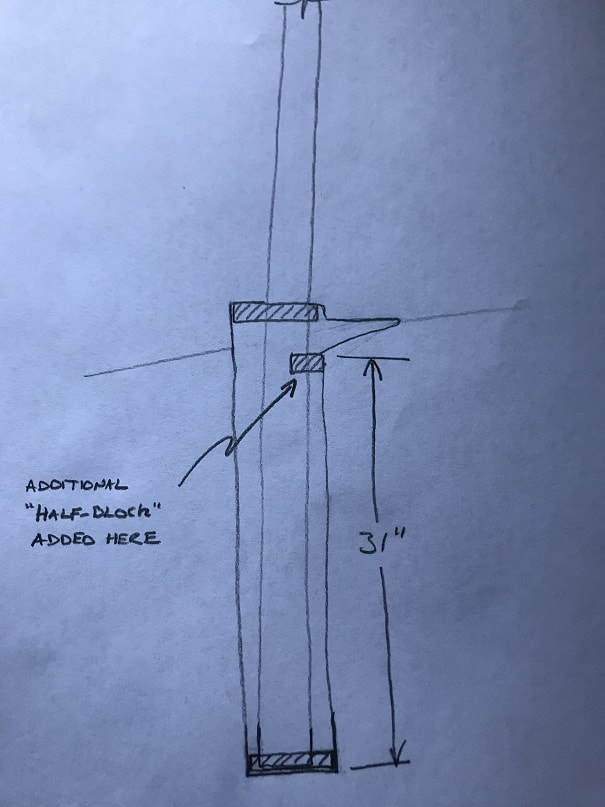

Shiver me timbers!!!! I made a mistake. The upper mast-block on my mast is at the correct location were there no mast step ramp, but it is too high up on the mast due to the existence of a mast stepping ramp that is part of my SCAMP mast trunk. The top of the the upper mast block on my mast is flush with the top of the mast trunk, but the angled mast stepping ramp lowers the aft side of the mast trunk as illustrated below. So, when I stepped my mast for the first time (pictured above), I realized that the mast was loose, because any aft pull on the mast pulled the upper mast-block backwards into the open space that is now the mast stepping ramp. With my upper mast block all nicely epoxied and varnished in-place, I decided to add third compression mast block 31" from the bottom of the mast , which will hold the mast snug against the topmost aft face of the mast trunk, done and dusted and very strong. Were I to build again, I would just locate the top edge of the upper mast block 31" up from the bottom of the mast. My system below is overkill regarding mast-block support-points, but based on how my build progressed, here I am.